Leaving Millport's Havens yard, the yard lead passes CM (Cinncinnati/Columbus-Millport) Tower with its diverging routes thru the diamond. The hopper is sitting on Fillmore Heights trackage.

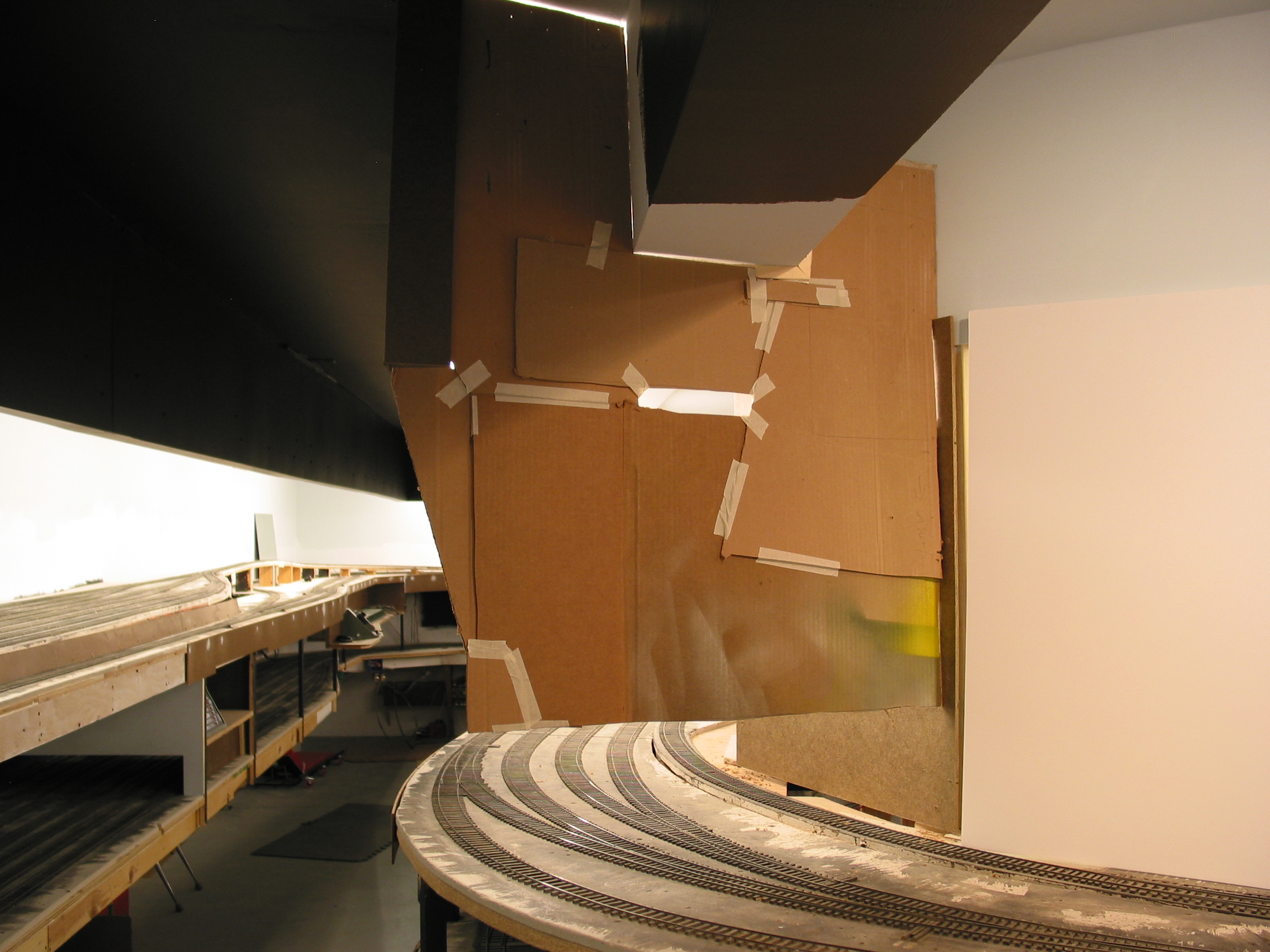

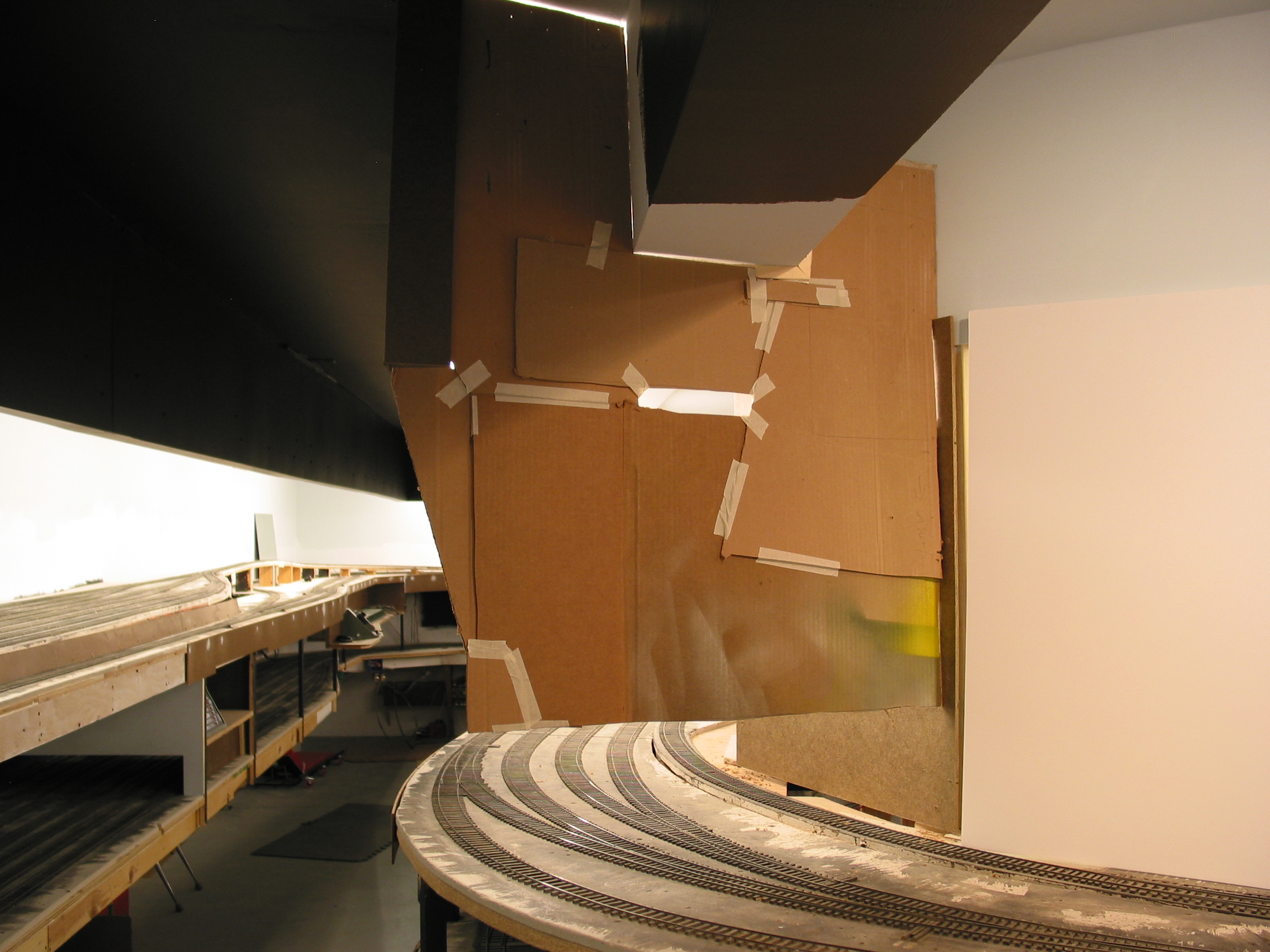

Once lighting was installed over Haven Yard, it became obvious that some sort of light block was needed. What to do?

The answer came in the form of a skyboard extending across the yard throat. And it would serve more than one purpose.

A 1/4" hardboard flat was first anchored to the existing framework. This will eventually be covered with a structure flat. Then a cardboard mockup/template was made. Already the light issue is resolved.

Looking the other way, a similar hardboard support and cardboard mockup were formed.

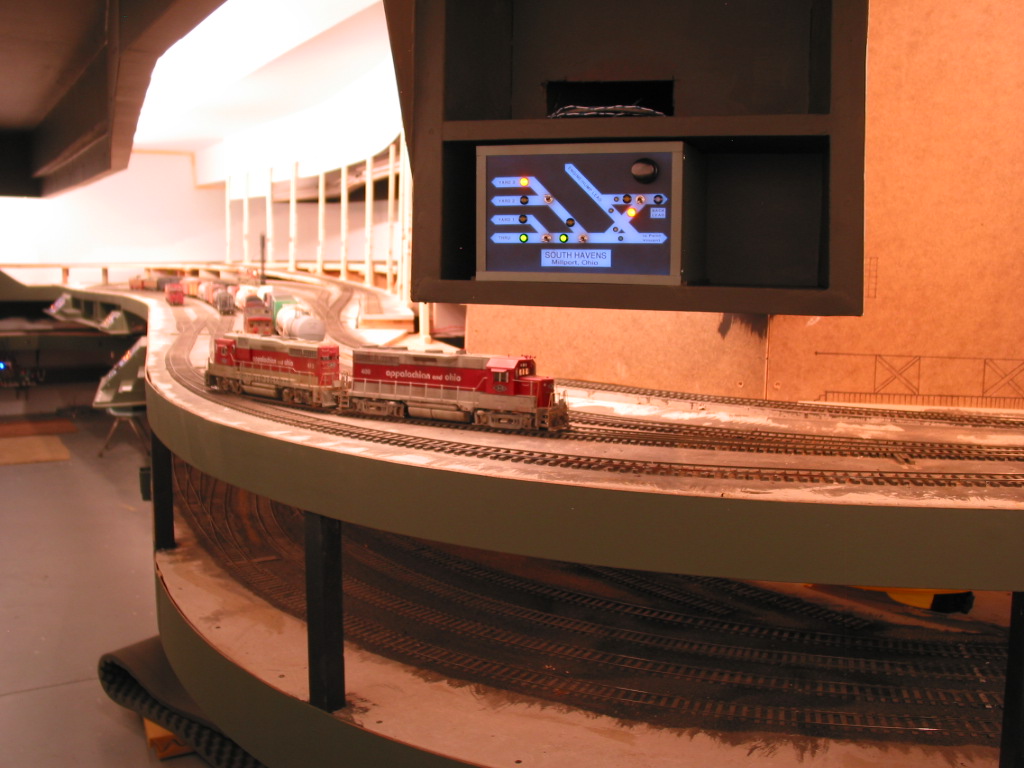

The skyboard is now seen as being actually a box which not only blocks the offending view of the yard lights, it will provide a home for a pair of control panels.

The templates have become 3/8" hardboard and pineboards form the interior shelves.

All fasteners are coutersunk and filled with MH Ready Patch.

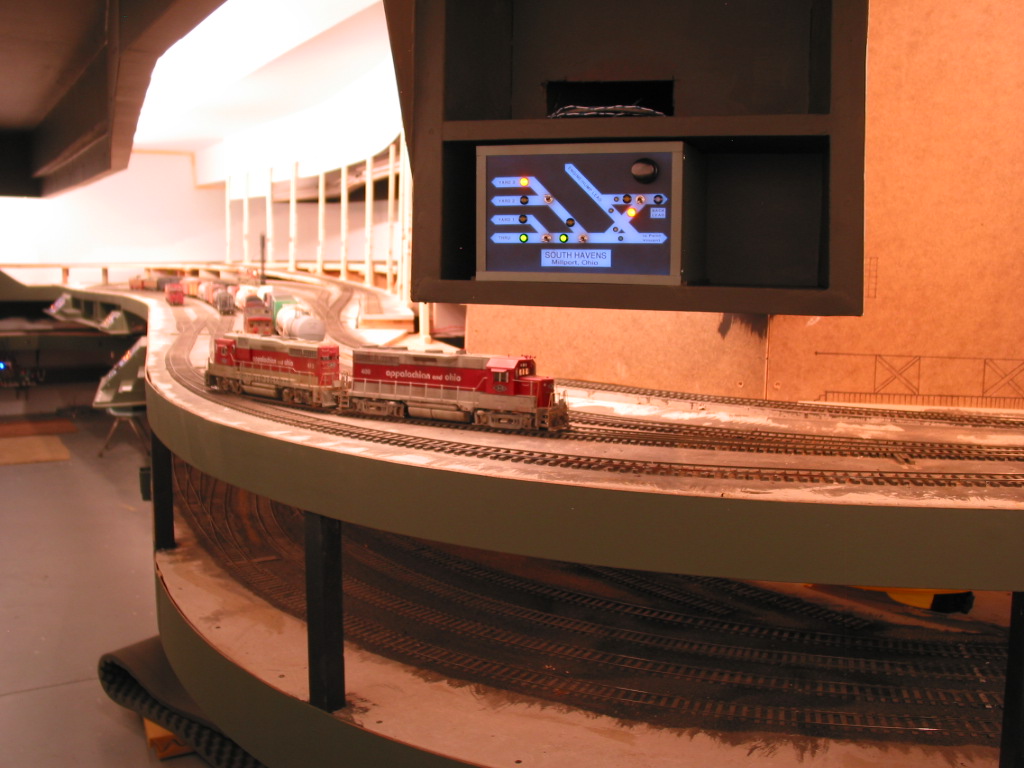

The South Havens yard panel has been installed to control the ladder below. The shelf above is for the CM Tower panel with its trackage just to the right. The bottom edge of this glorified skyboard/lightblock will be hidden by cross-track piping and conveyor housing from the rear industry.

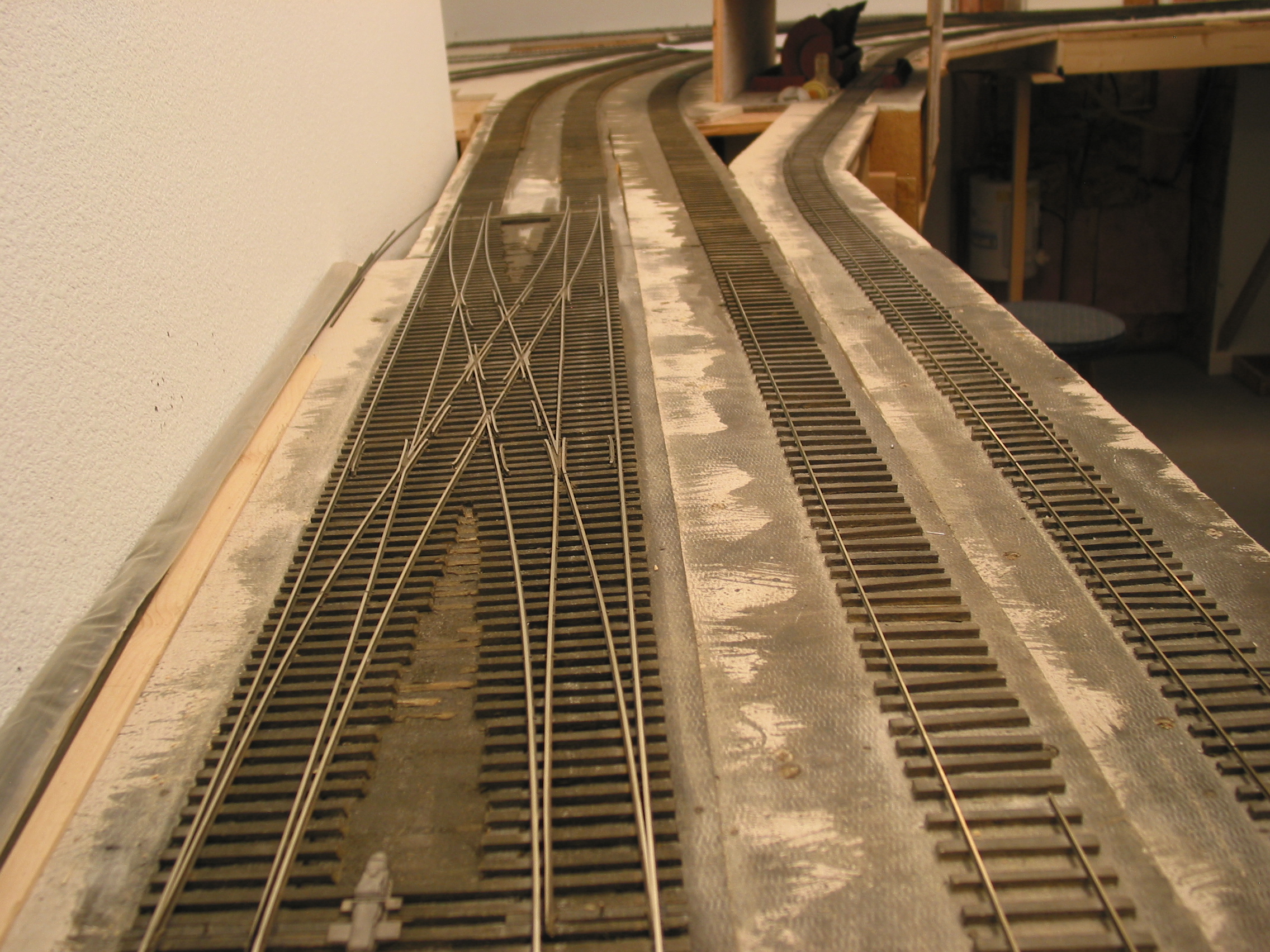

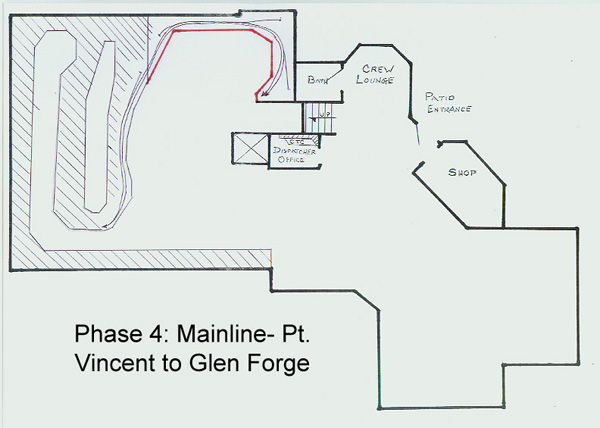

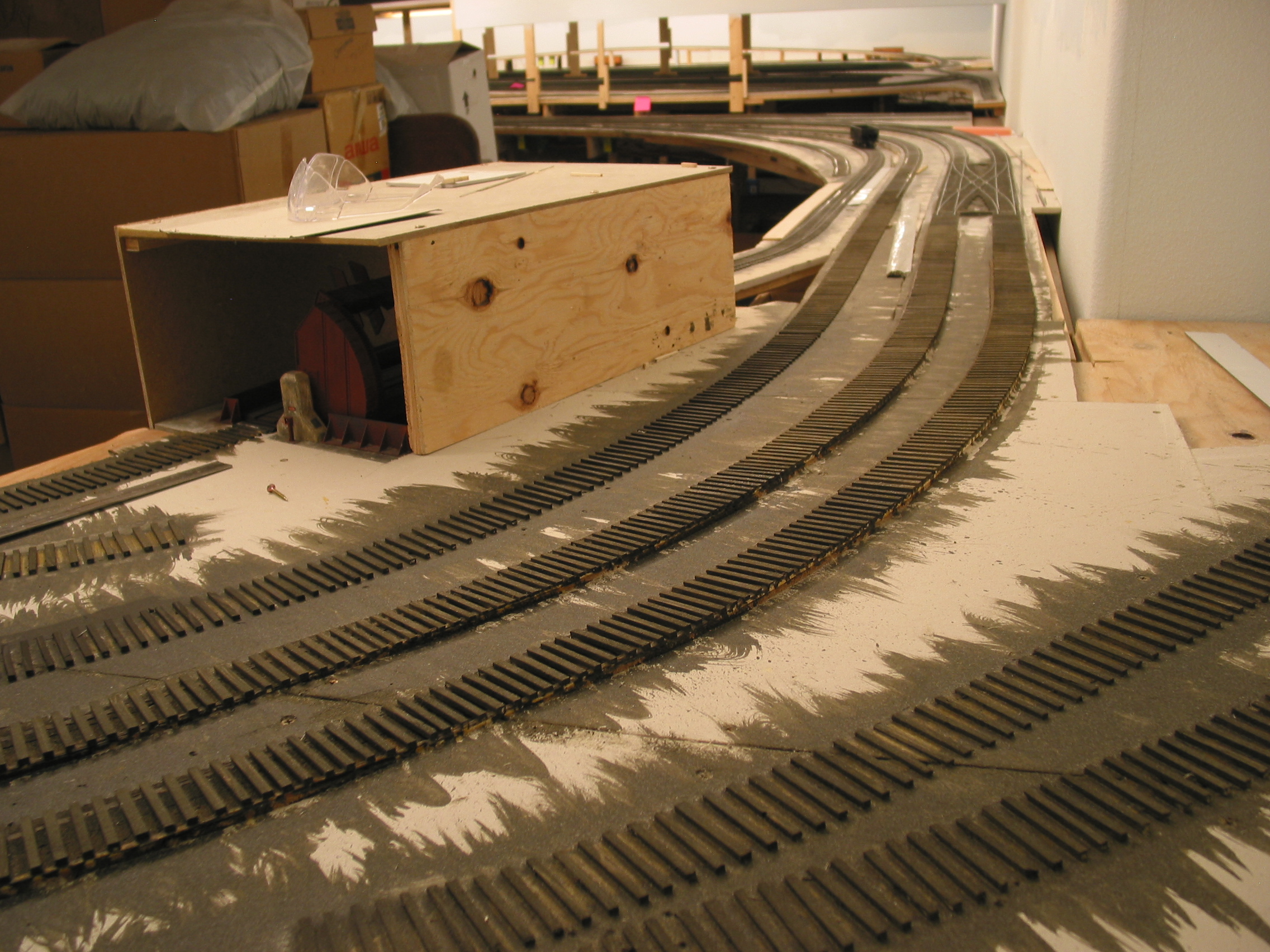

Leaving CM Tower, we come to Pt. Vincent and the beginning of the A&O double-track mainline. And, the beginning of the massive International Paper Co. Here splines are finding track locations on the micore subroadbed.

Splines, clamps, thinking thru operations.......

The peninsula styrene skyboard is being added at this time as well.

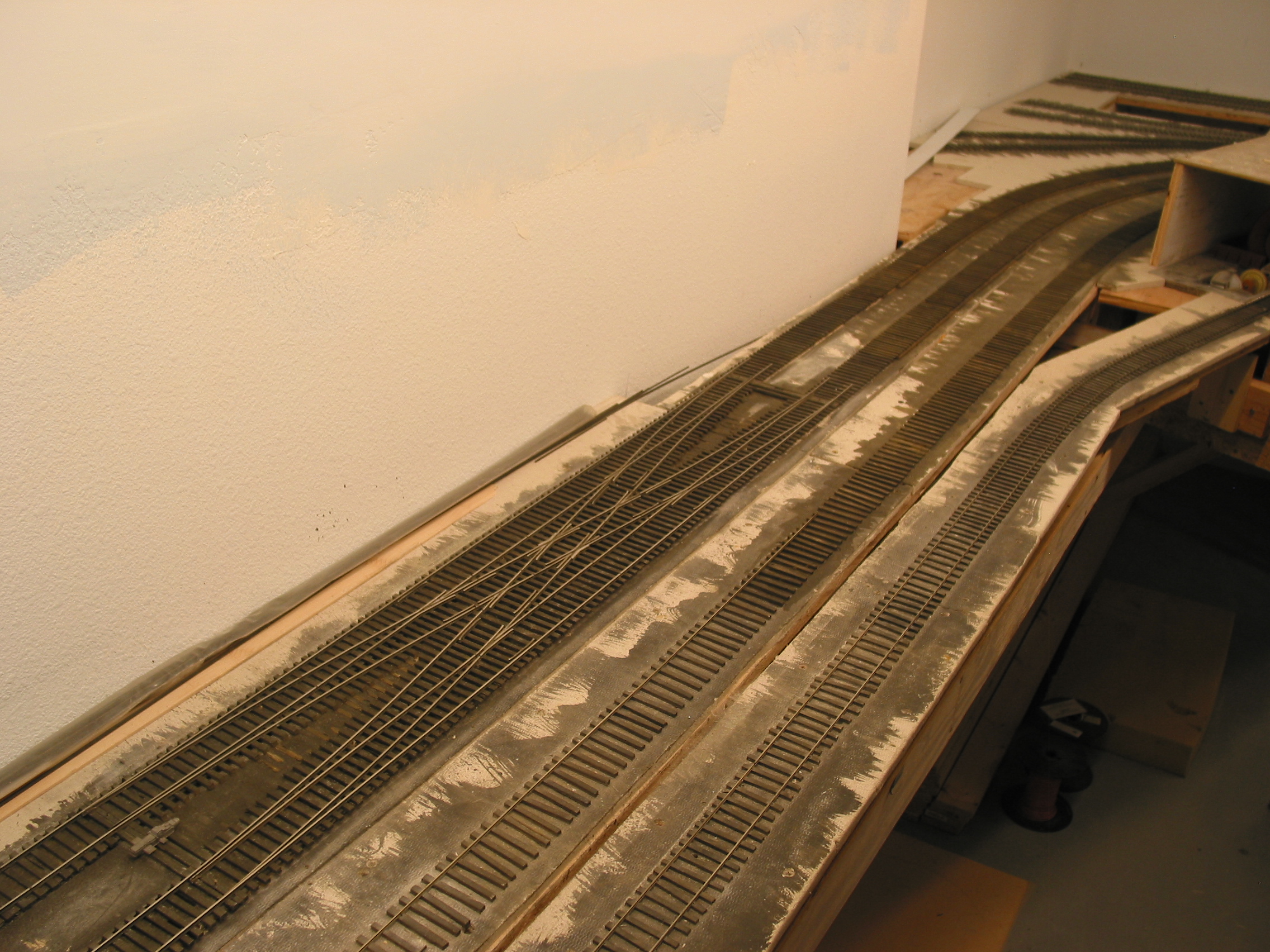

The first tracks encountered leaving CM Tower are the pulpwood, wood chip, and coal power plant tracks. A very congested bit of trackage here (see Forum, "Crew Logs" for a close up of this construction.)

Wood chip and pulpwood loads will be removed once cars are spotted.

A sorting/holding yard will help the switch crew of the Mill Job. The switch begins CTC territory and is known as CP (control point) Pt. Vincent.

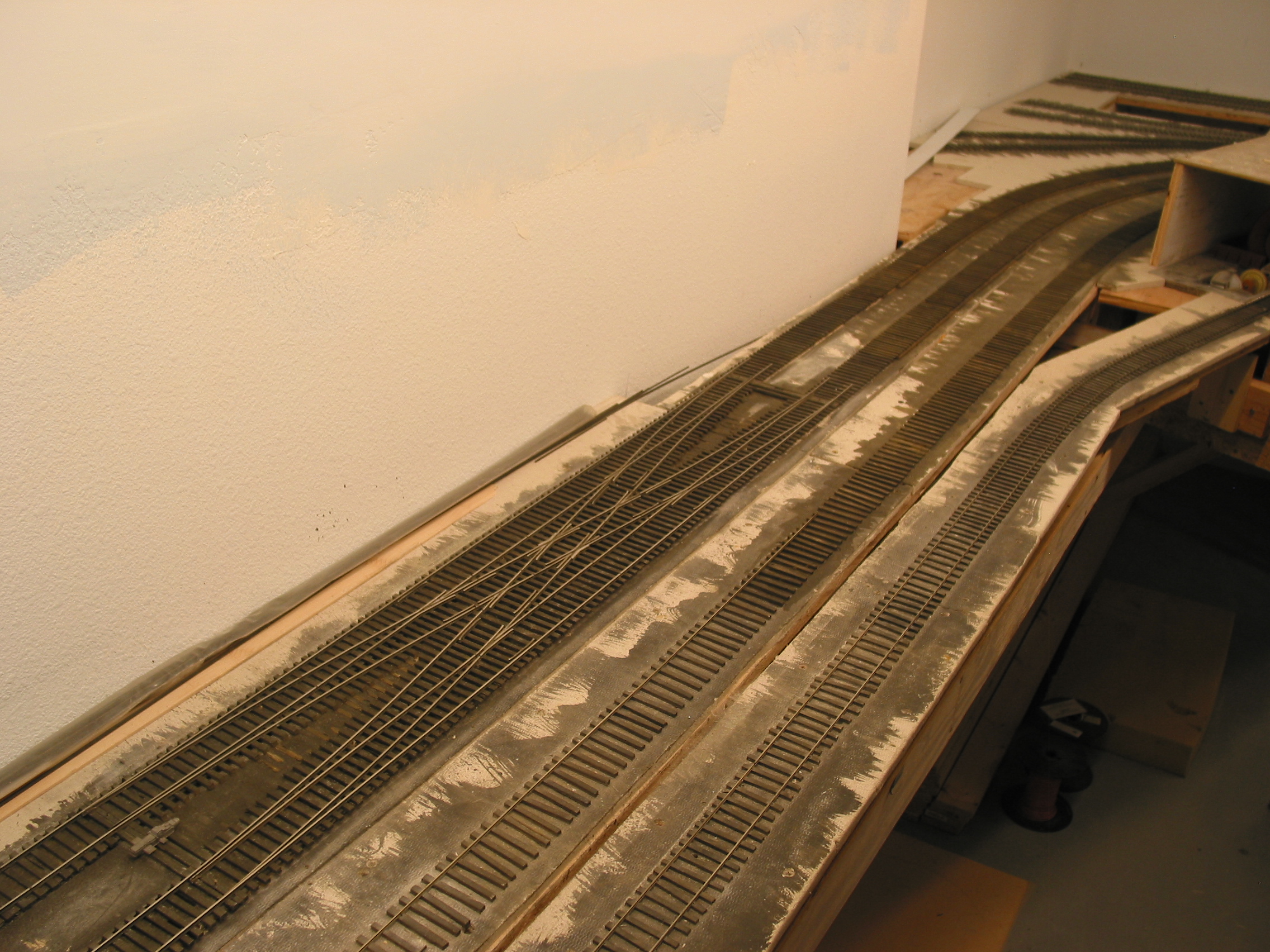

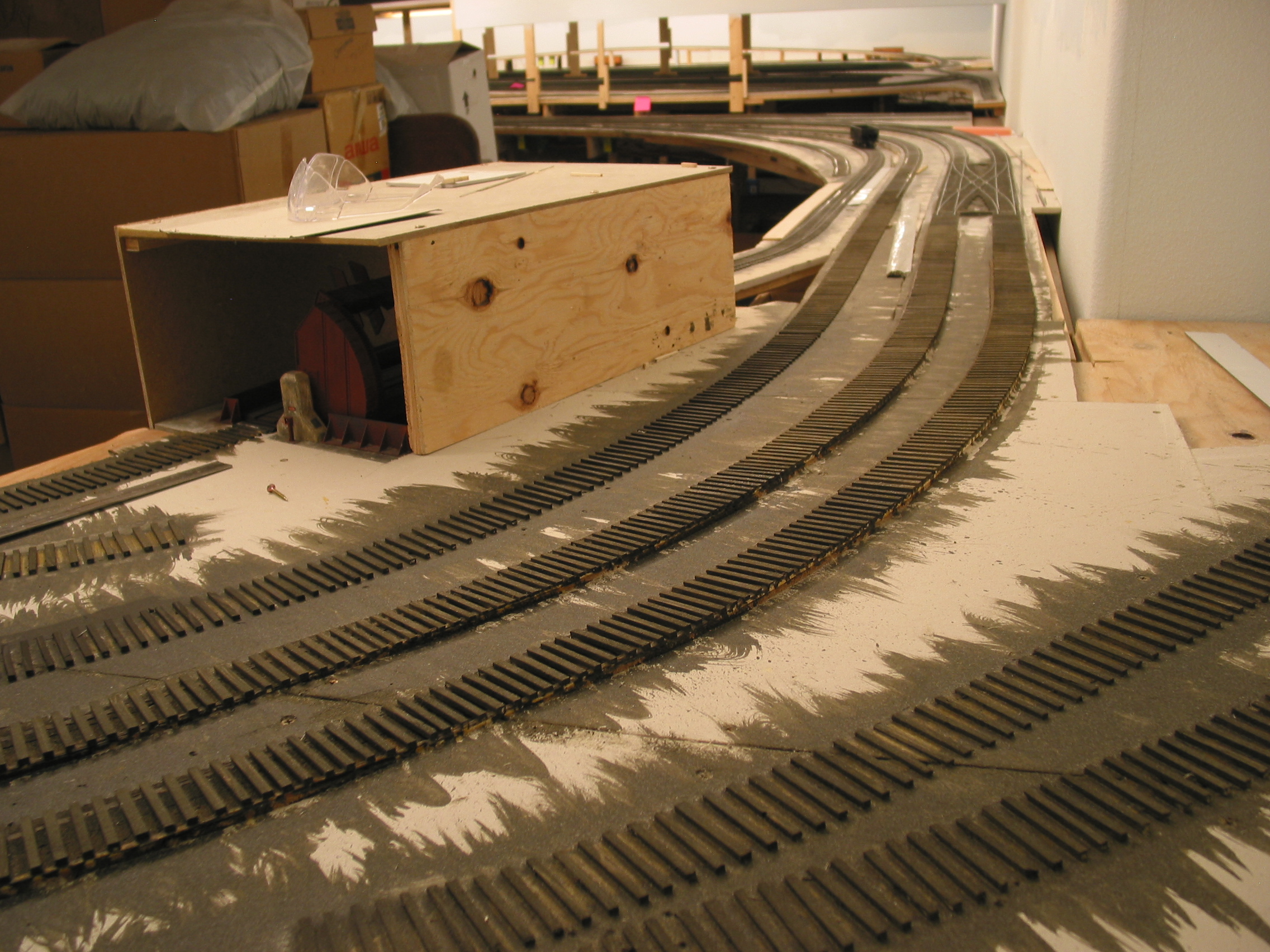

The splines have become ties with rail attached. Large mill flats will span the length of this 32' mill complex.

Looking the other way, the double-track main begins to rise enroute to Glen Forge. The T-pins reveal switch-building is still in process. The only track salvaged from A&O 1.0 is the curved diamond in the distance. Large paper warehouses will enclose distant trackage.

Point Vincent is the raw materials end of the International Paper Co. with pulpwood and wood chips coming in, along with coal for power generation. Shelf cubbies provide a place for the removed loads once cars are spotted.

The finished Pt. Vincent work station with its removed-loads cubbies (lower two) and card file shelf (top). Rope lighting for night ops lights each one. Effort on the fascia helps provide a shadow-box effect for the railroad.

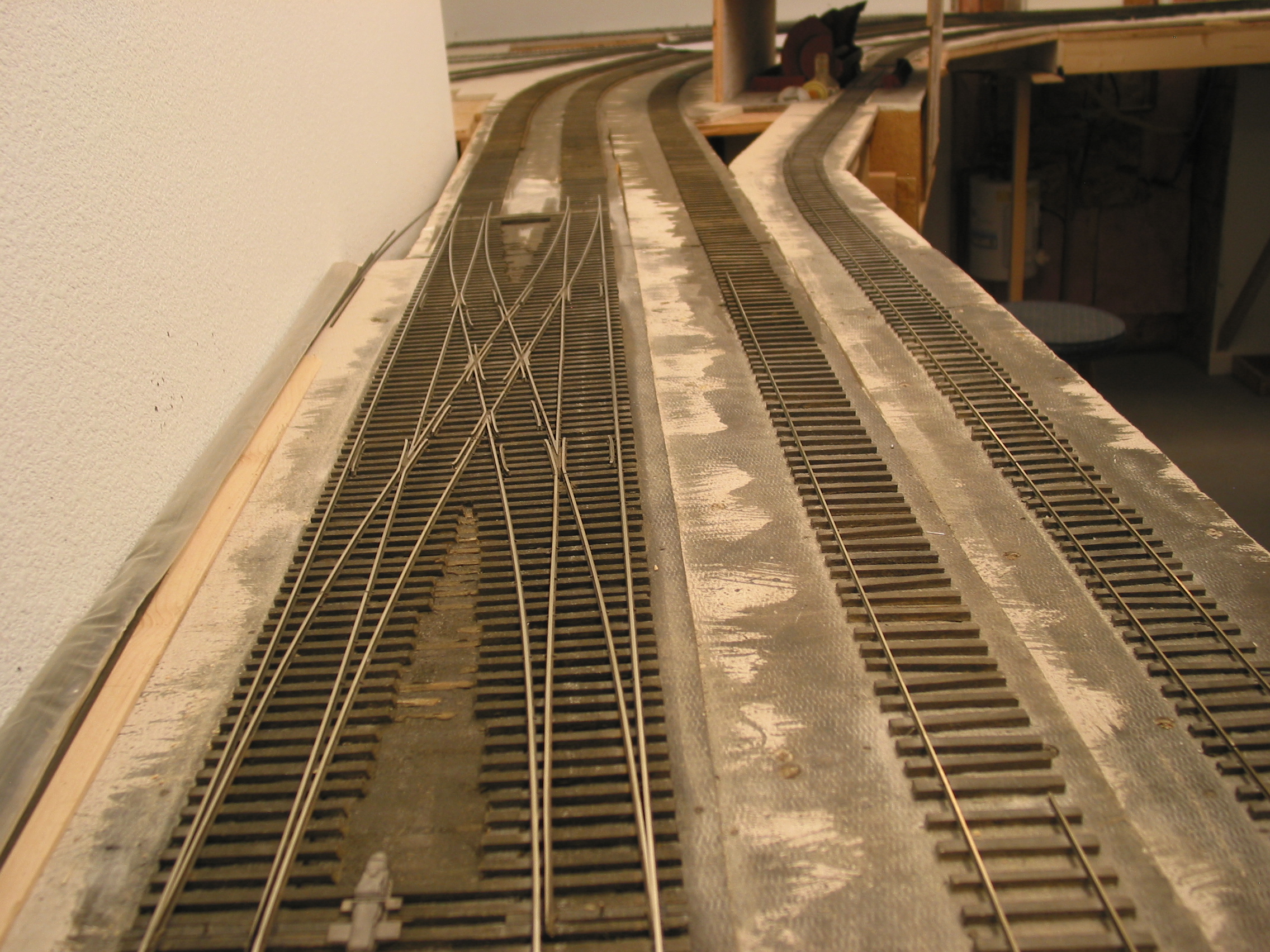

After arcing past the last of the International Paper trackage, the double-track main comes to a double crossover known as Bayfield.

An engineer's view of the Bayfield double-cross. The track to the right is the coal arrival and departure and the far right is coal rotary empty receiving track.

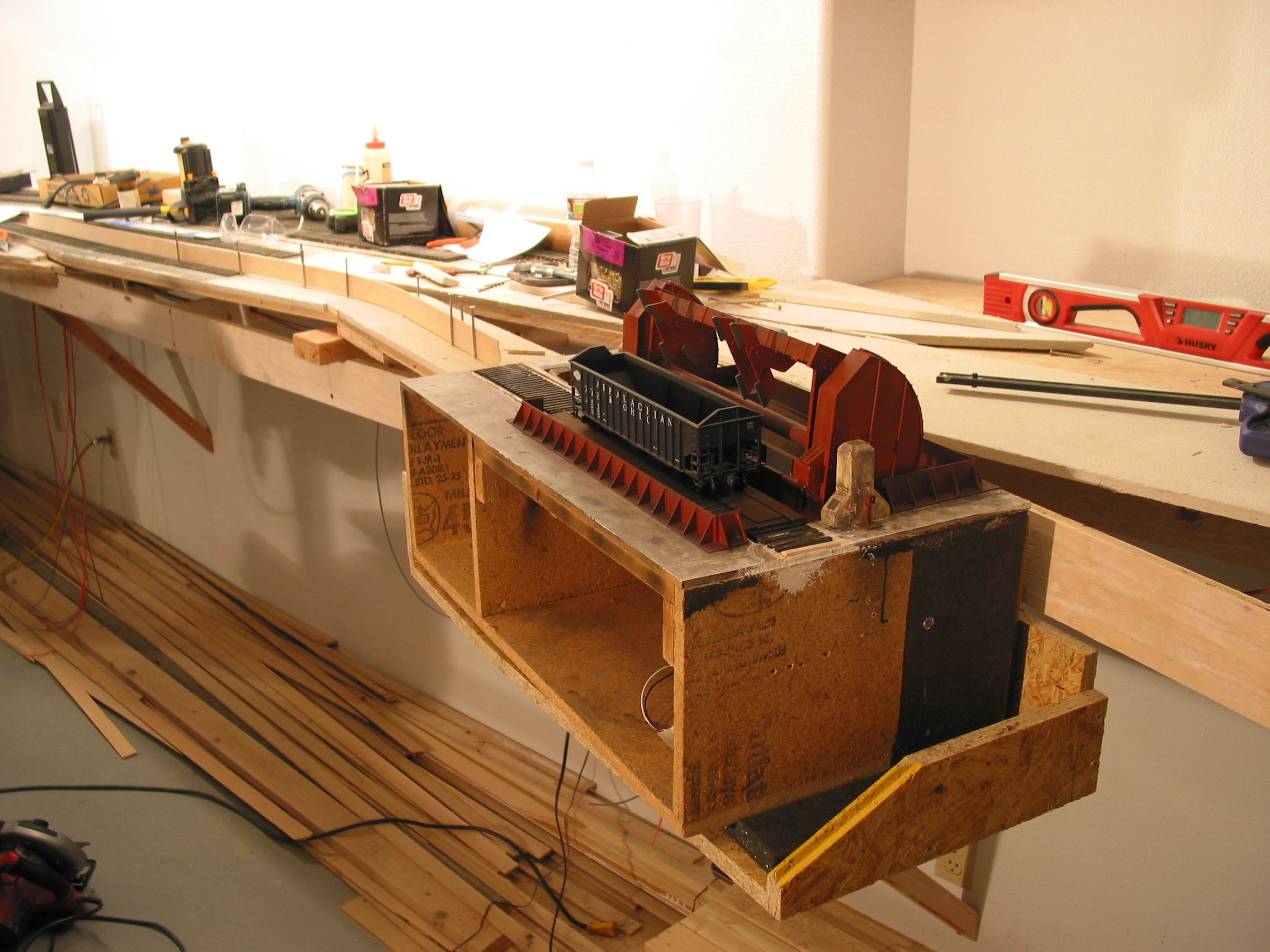

Time to fill more basement. This is Glen Forge. A slide out section is necessary in front of the Rinaii hot water heater for service reasons.

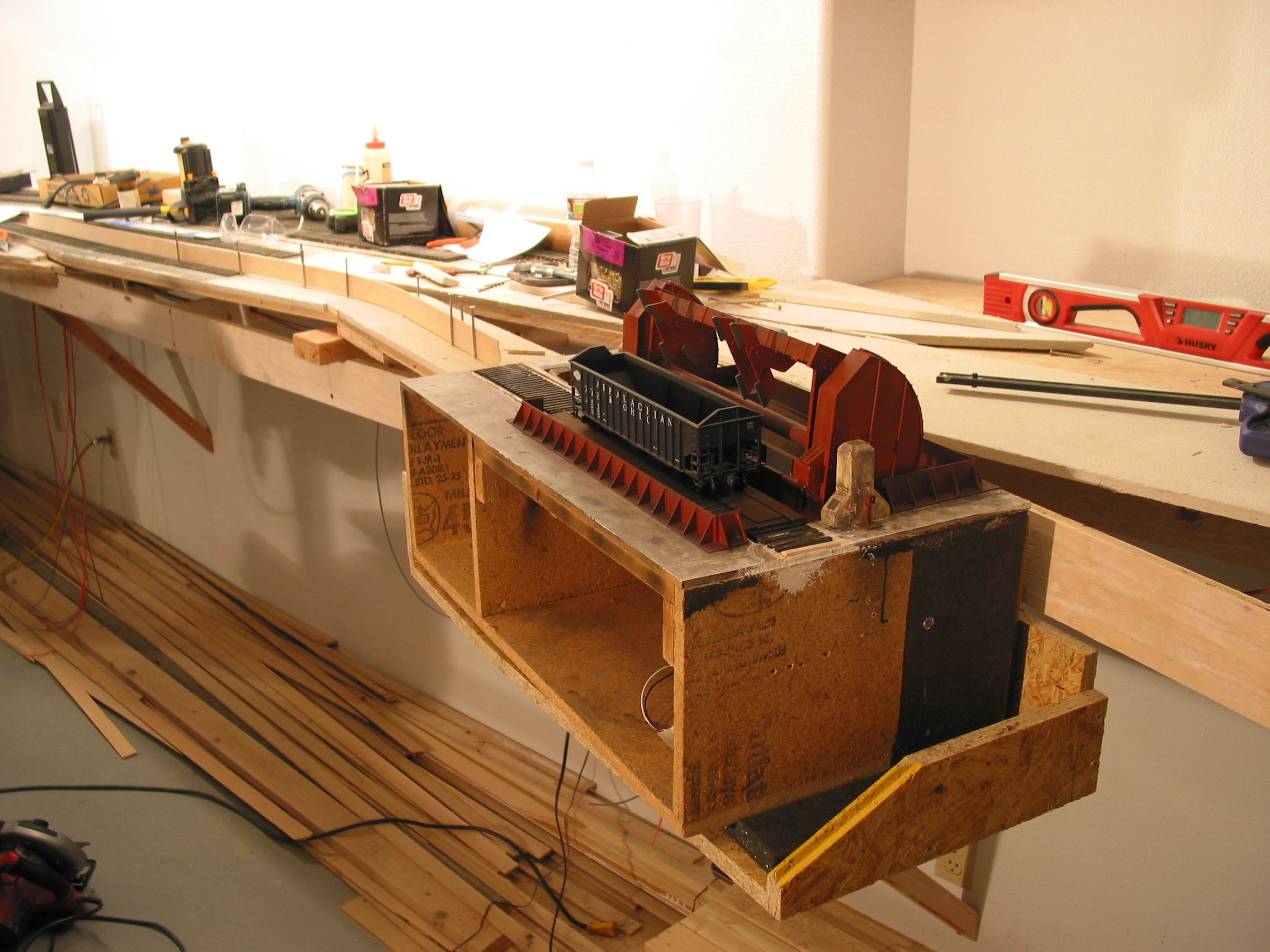

The Whiting Rotaside dumper been secured into a cradle, assuming its new place on A&O 2.0. A pair of coal barges and tug will be parked along a finished river scene in front.

Splines were used to align the rotary trackage with the empties track. A slight grade automatically pulls the hoppers away as the next hopper is placed for dumping.

Likewise the splines dictate the track locations into the rotary.

The Glen Forge tracklines are established, being careful to not locate any turnouts across the joints of the slide out section in front of the Rinaii.

The ties are in place into Glen Forge. The Bayfield double-crossover can be seen in the distance looking down the mains. A plywood cocoon encases the rotary to protect from damage during this phase of construction.

An overall view of the Glen Forge ties ready for rail. Like everywhere else, the final track arrangements have been refined for operation. Besides the rotary, Glen Forge features the Southern Baking Company with its flour airslides and the Whirlpool appliance factory with its coil cars and 40' hy-cubes.

Vince installed the first of the CTC signaling system under Bayfield. That's an "S-mini" for the Chubb CMRI below, and above is a bank of detectors for the many control points in this section of the railroad.

Vince lays in the rail for the Southern Baking Co by standing in its access hole. This opening will be always available, but invisible by being inside the tall structure.

Here I'm laying the rails into Whirlpool which are lengthend by piercing the wall into the stairway area. The completed throat turned out to be a 3-way and lap switch.

The finished Whirlpool end of Glen Forge. The double track main at right-cneter begins its 2.5% climb to the Ohio River bridge from here. The hole will be for emptying coal hoppers (see Fillmore Hts., phase 3).