Car Preparation

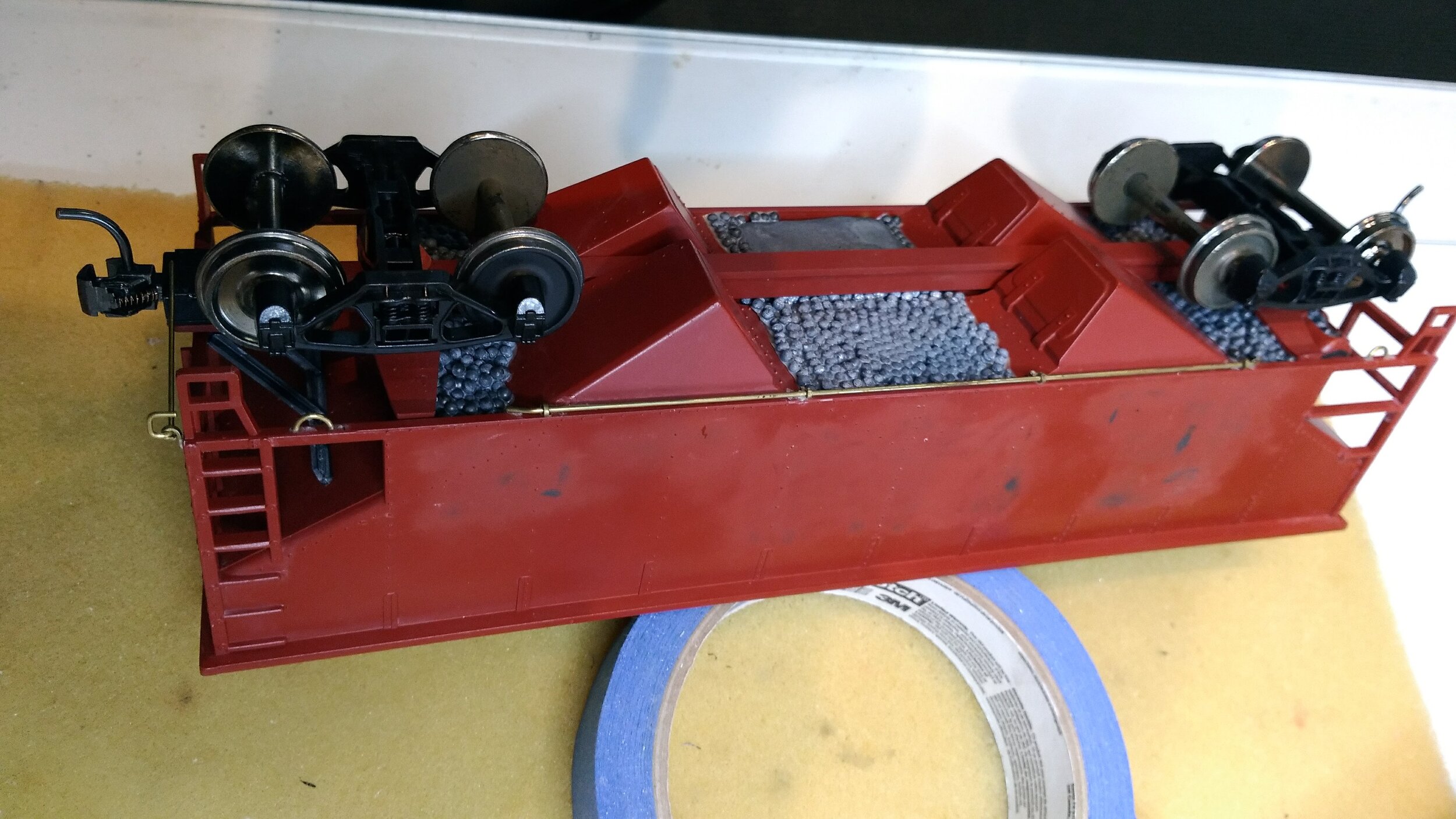

Car preparation to achieve standards is a necessary part of good operation. Here a soon to be painted Weaver offset two bay hopper has received necessary extra weight using lead shot and white glue. This brings the car to 14 oz. for a 36’ car (16 z. fpor a 40’ car).

The hopper was paint stripped and pull rings, train line, and cut levers details added. In O scale- it’s noticeable. Wheelsets are by Intermountain and have one resistor added to an axle per truck for CTC detection.

The A&O CEO likes peaked hoppers, so a styrene master was made, molded in RTV rubber, and cast in urethane. Then .010” styrene is cut, trimmed, filed, filled as needed, and added to the hoppers. The styrene acts as a bridge plate for strength. The notched end allows access into the hopper from the ladder on the B end.

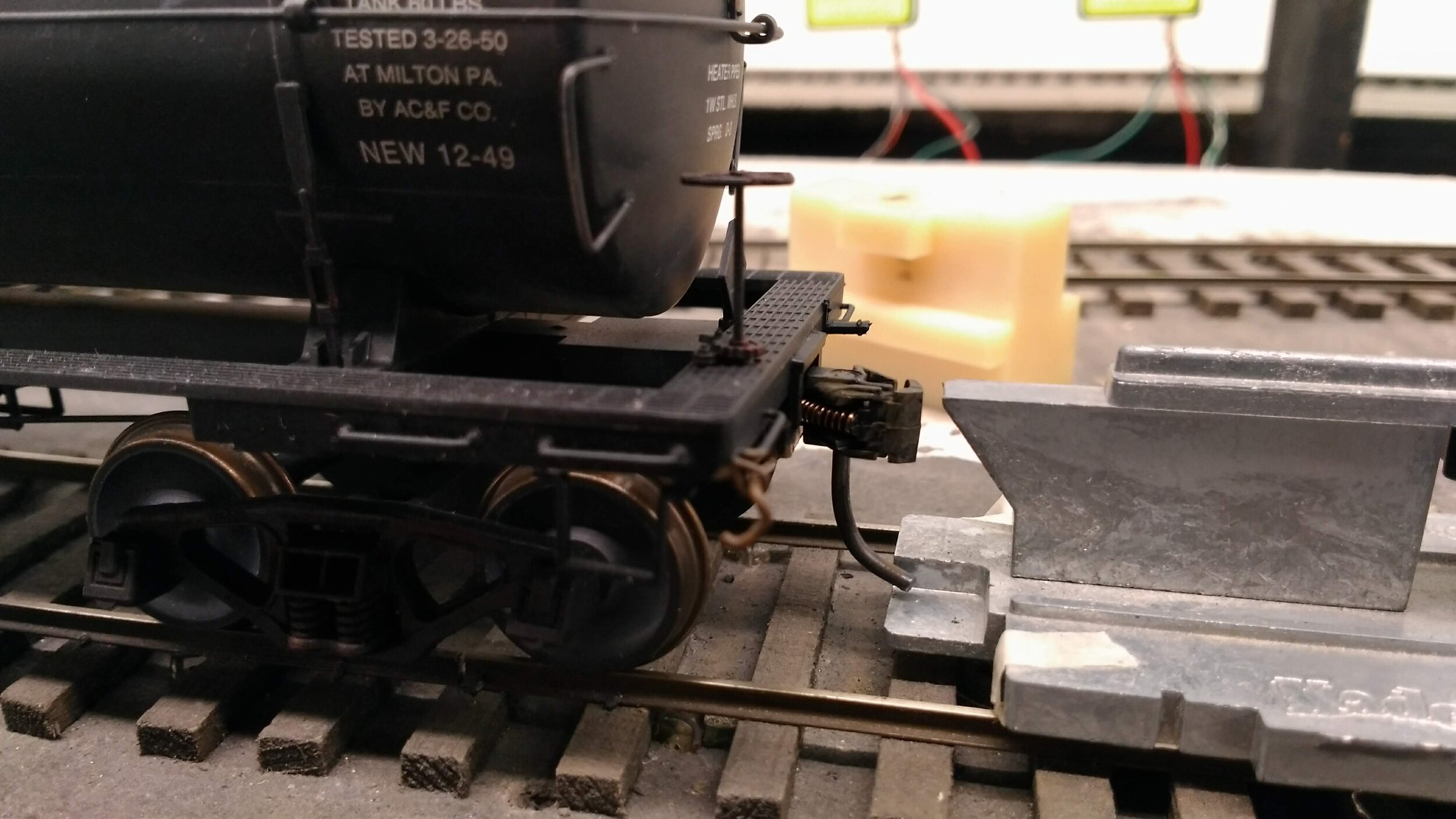

Coupler height is checked using a gauge Bob made on his mill.

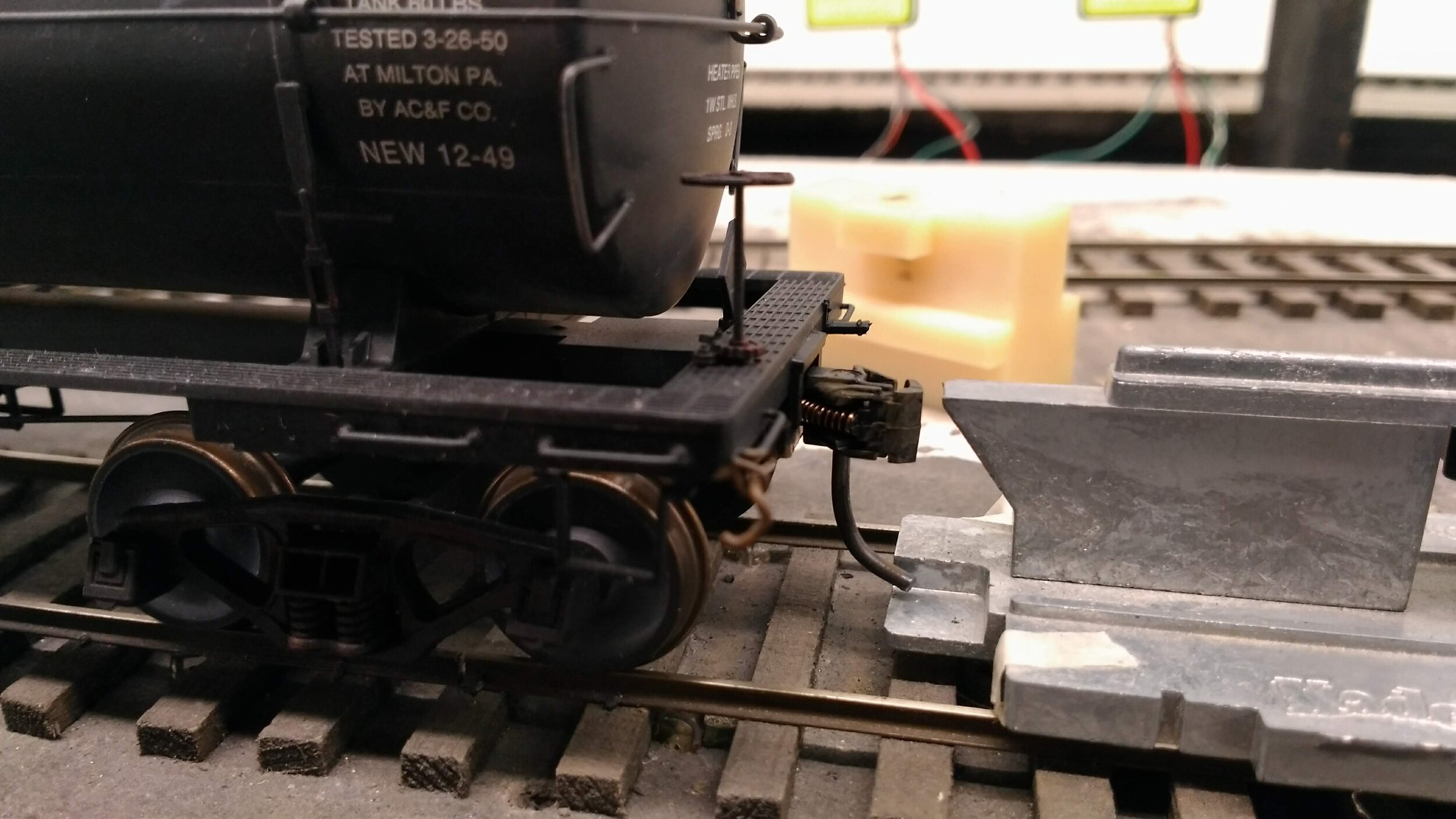

While some railroaders remove the Kadee “Draft Gear” uncoupling pin, they are required on the A&O because of remote uncoupling, such as….

….the 16th street hump where a string of permanent magnets uncouple the car as it crests the hump. Properly working couplers are not an option to make this whole operation work. Obviously nothing goes straight from box to layout on the A&O.

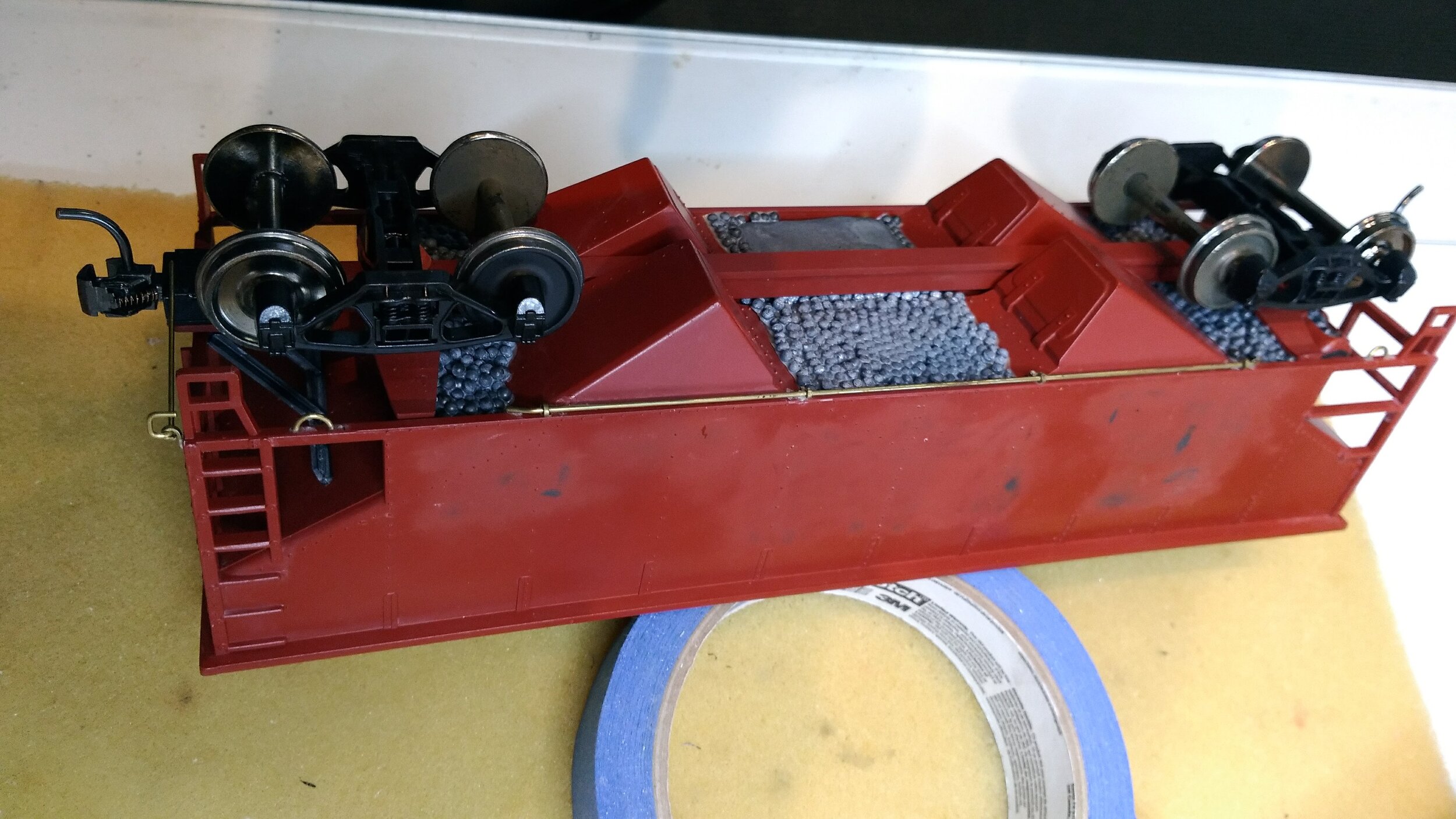

I made a tank car cradle for inverted placement. The red straps are pieces cut from a square of rubber available in the plumbing section of the hardware store. Handy device.

For cars that roll too frisky down the hump, even when the last retarder has stopped them cold, I added .005 phosphor bronze across the bolster in arc to provided resistance on the axles. They are attached with a small screw thru a predrilled hole. The phosphor “wings” can be tweaked to achieve the correct amount of resistance. For heavier cars I’ve used .008.

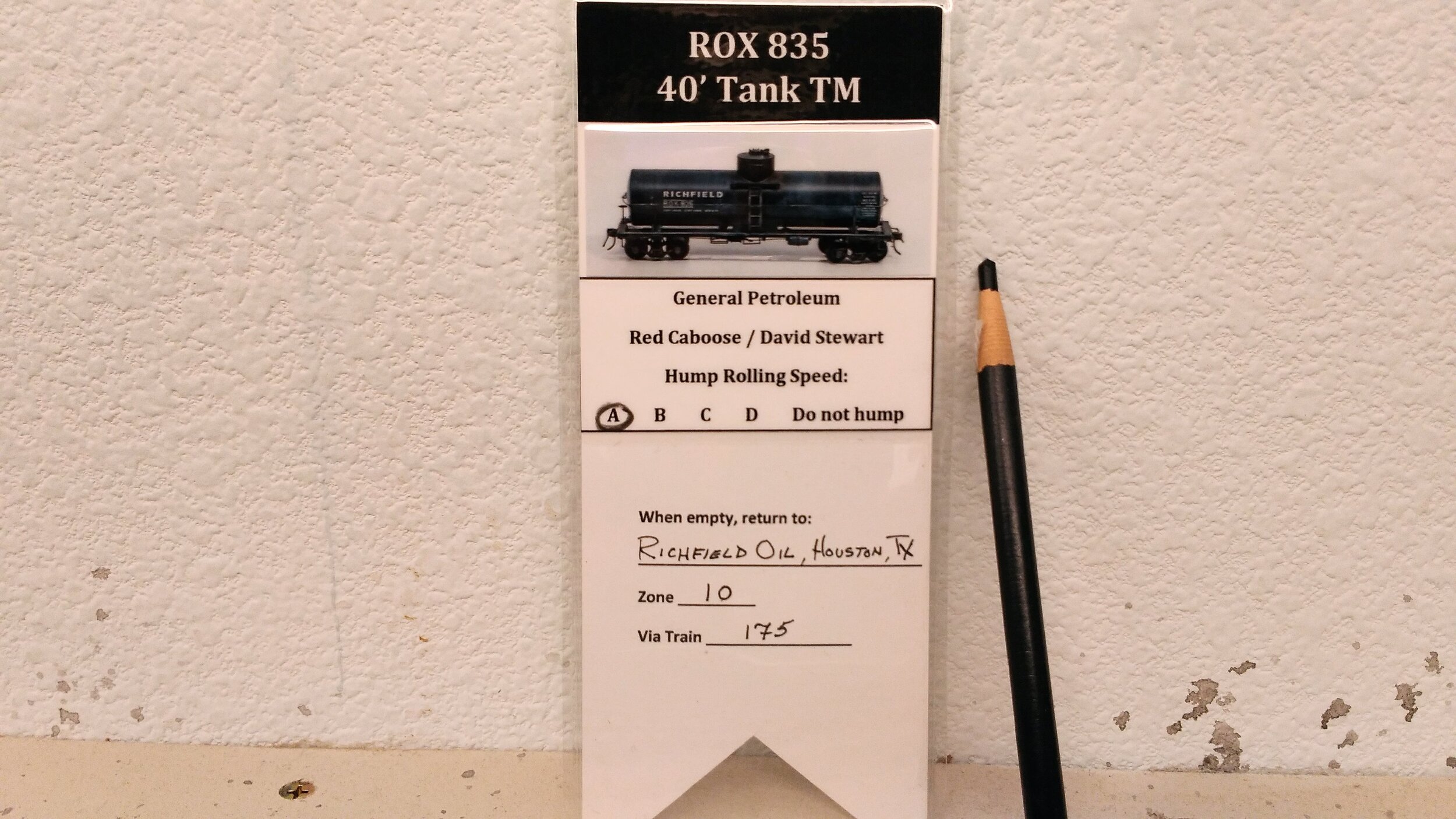

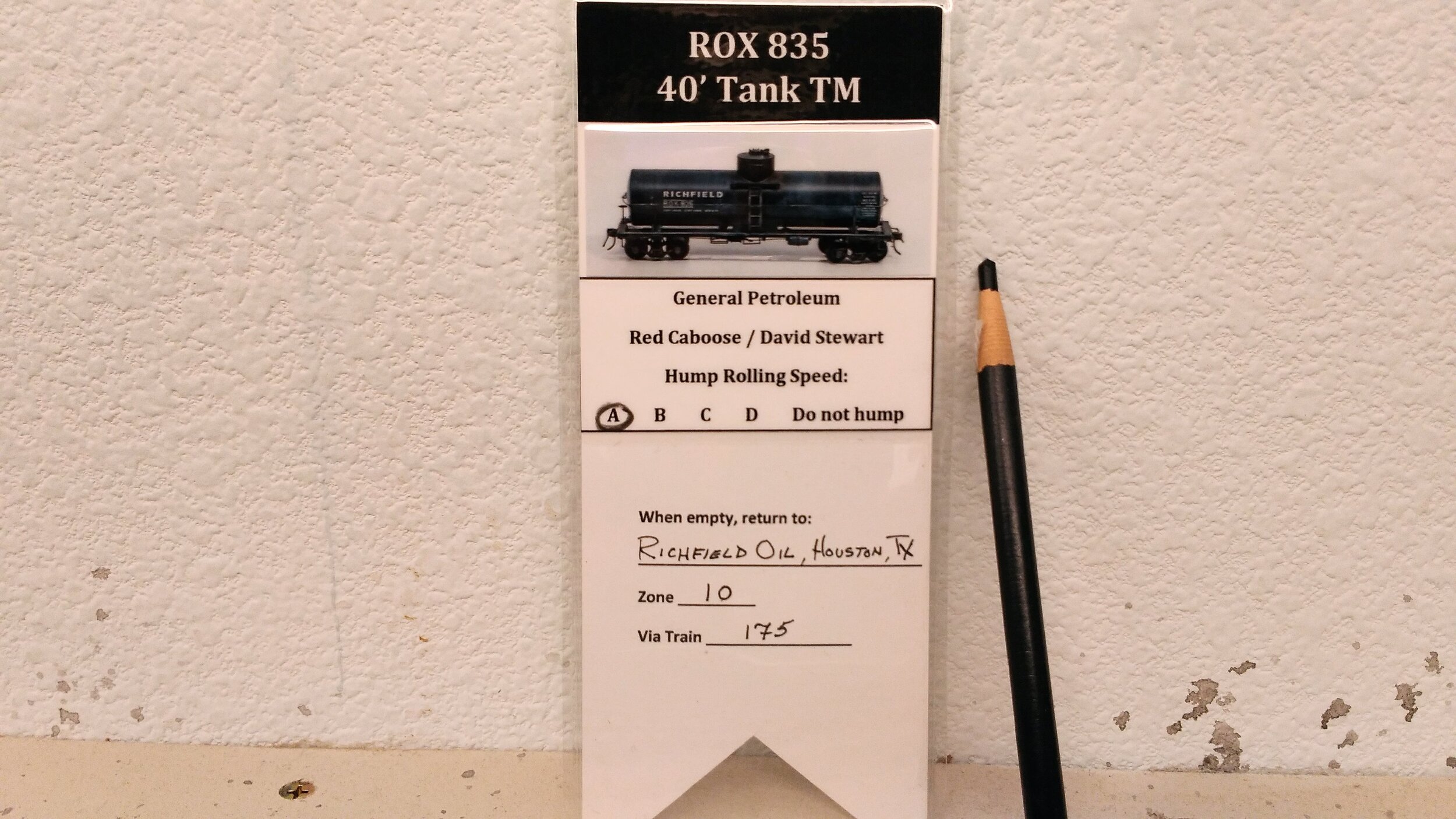

Time for a test run. Placards A -D tell me how they perform on the straightest track into the hump bowl. I try to make every car an “A” roller. That way an empty yard track can be filled from the end forward by any car that may present itself. This car needs “its wings clipped…tweaked.”

A little pulling upward on the phosphor bronze and now Mr. Richfield is an “A” roller.

Finally ROX835 is ready for service by circling “A” on the car card. This was previously done with a grease pencil, but now with a Sharpie as the grease pencil proved too easily removed by handling.

The “Hump Rolling Speed” is a guide for the hump operator.

This tank car is getting some crud removed from service days on A&O 1.0 via a Dremel and wire brush wheel. It’s also a little sluggish so some fine Nano-Oil will do amazing things.