Car Forwarding

The A&O CEO likes car cards, and it fits my 1968 time frame. And I like picture car cards for fast recognition/pairing by the crews. Cue photographer Bob.

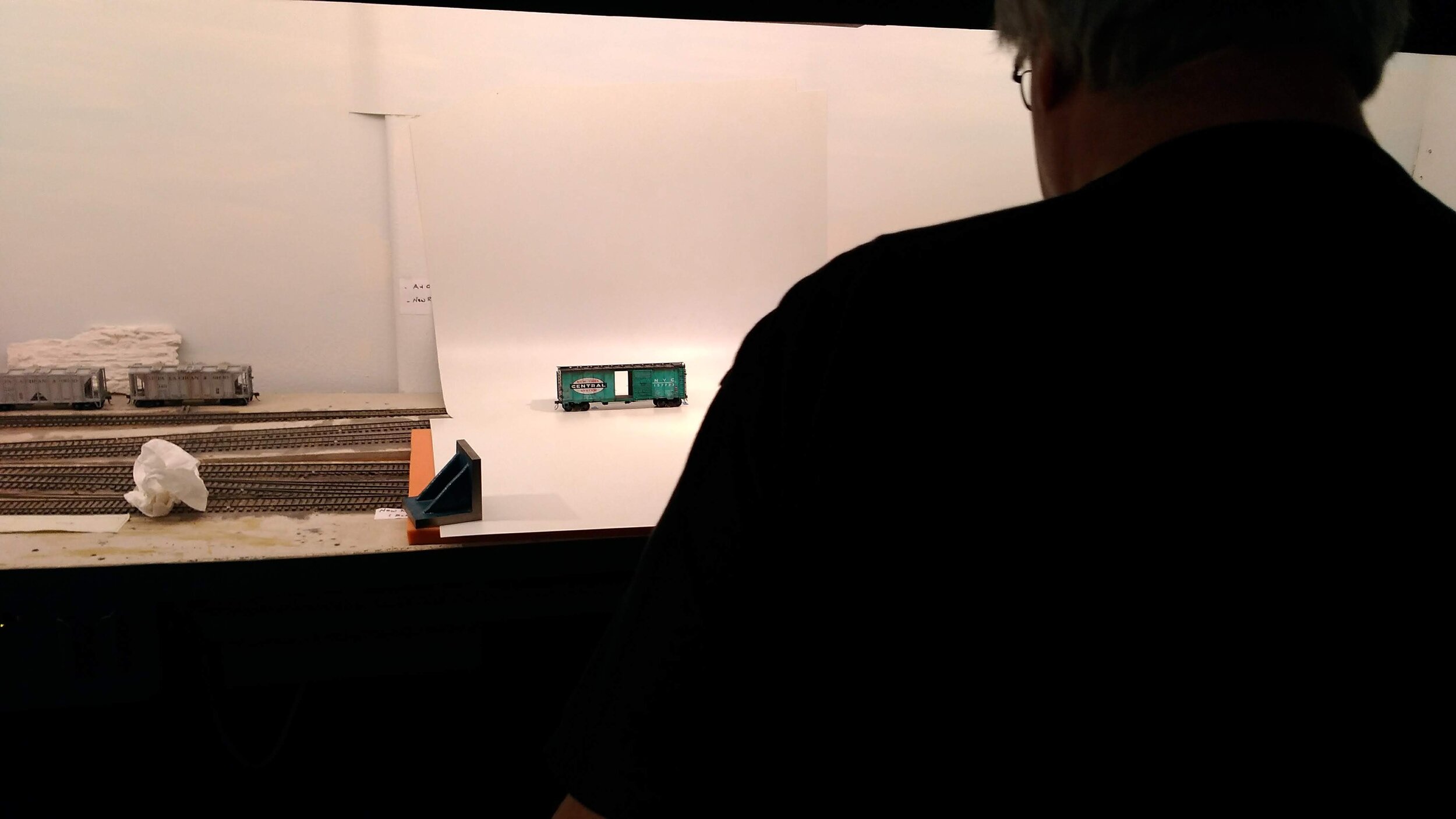

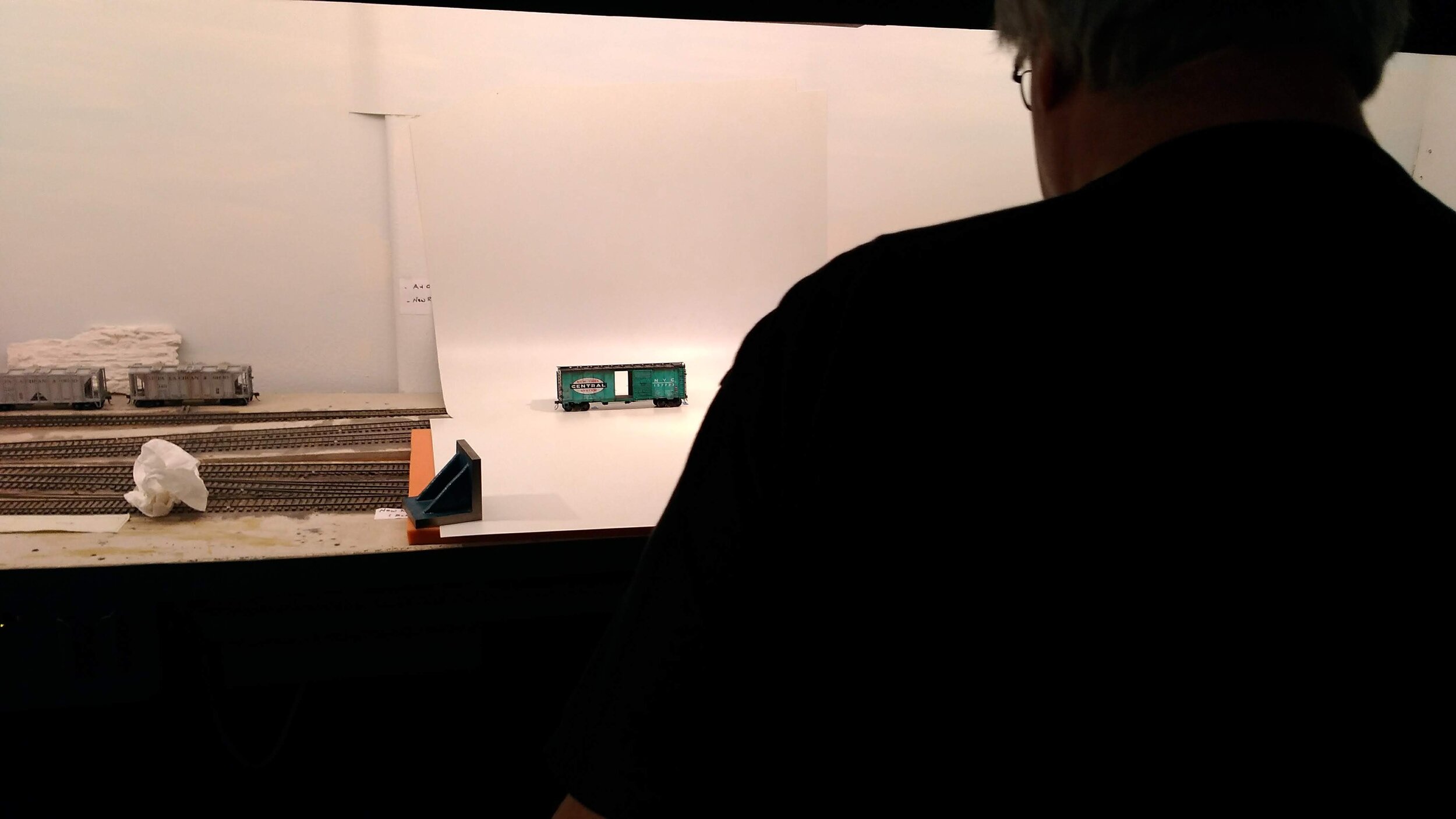

A styrene sweep was set up in, appropriately, Sobol Springs where mass portraiture of weathered cars sat one by one.

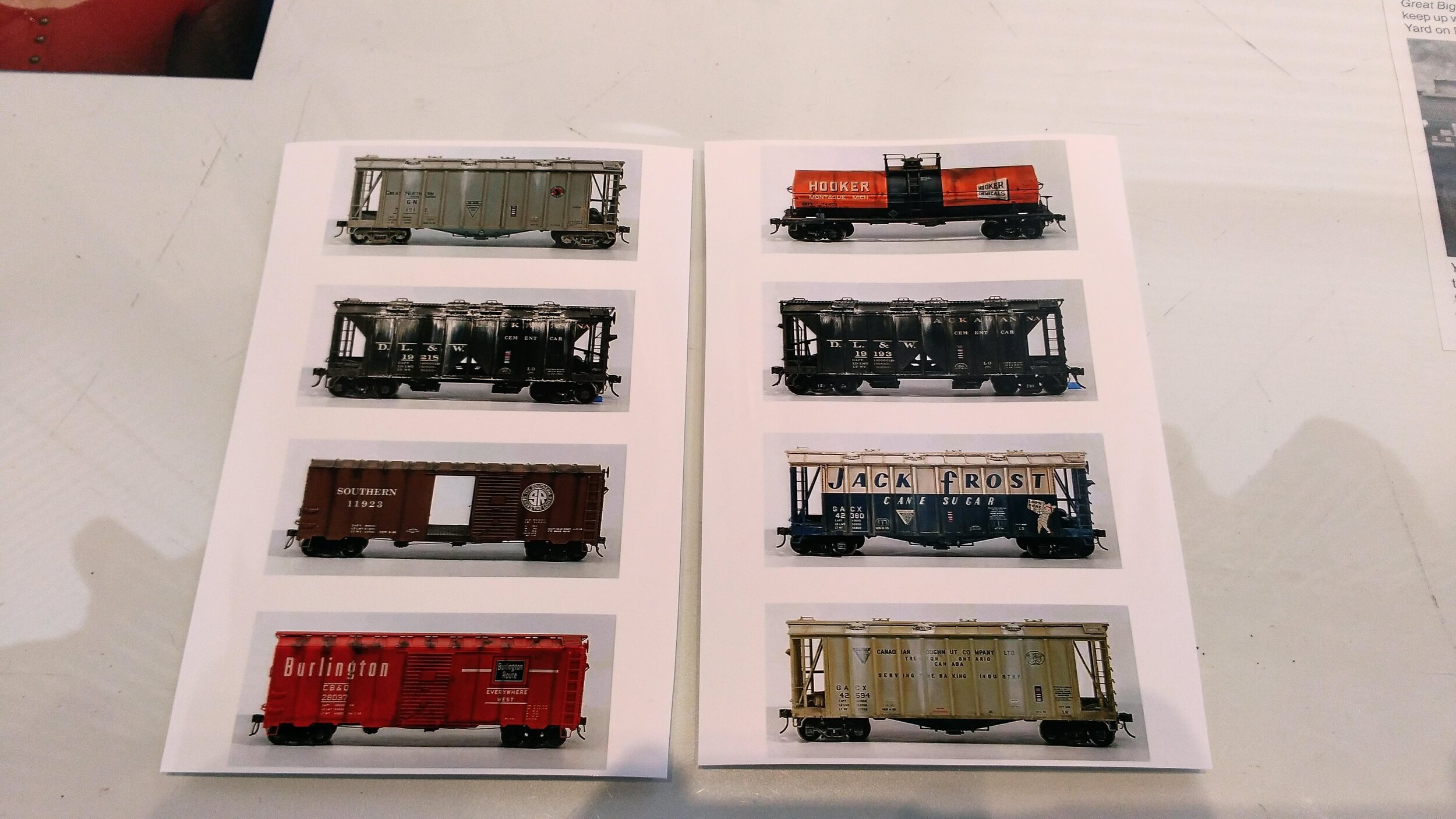

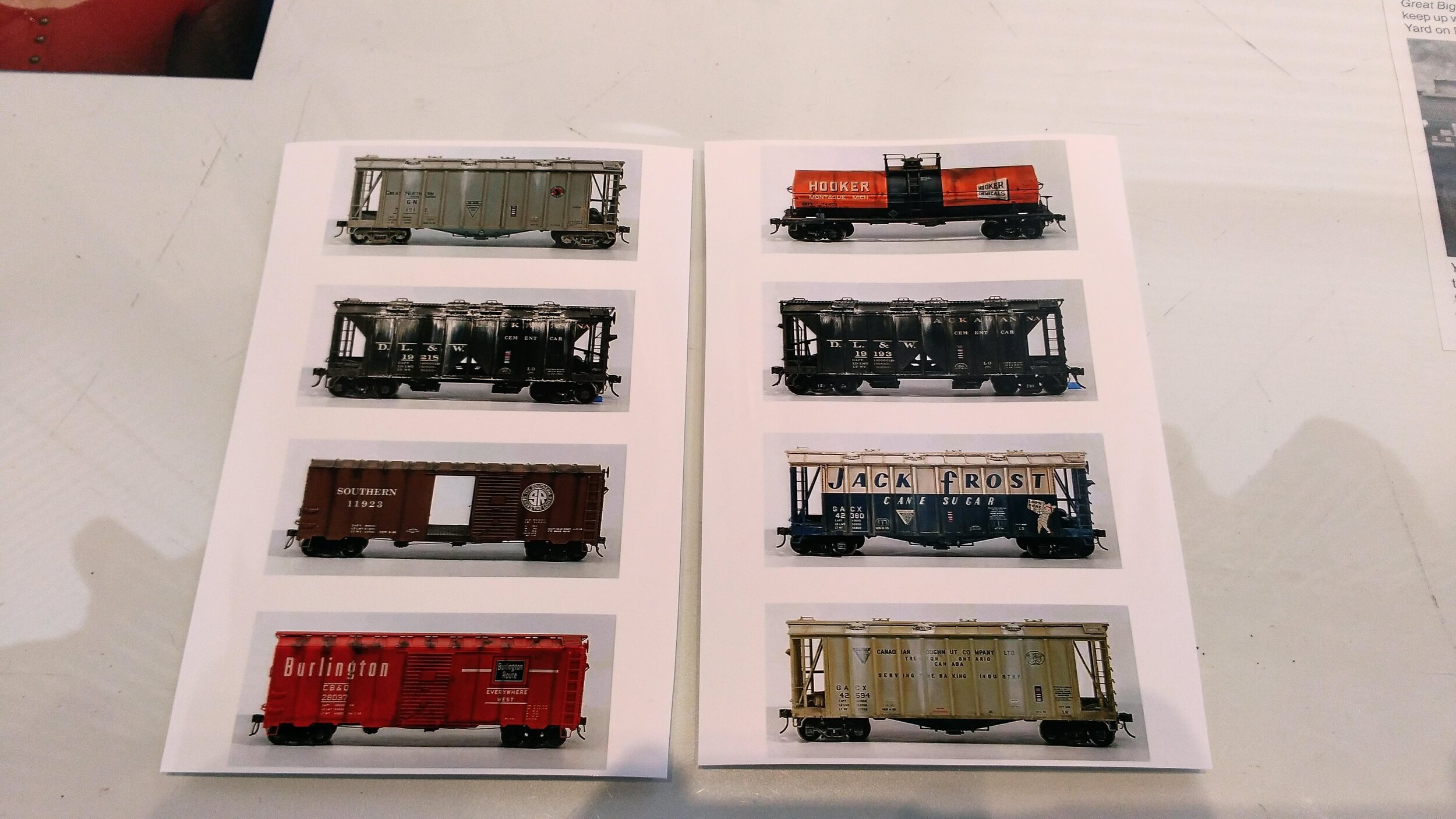

Bob digitally arranged the photo files and sized so that he could submit email the file to Walgreens for glossy prints. Four cars per print at $0.15 per print- cheap enough. Thanks again Bob!

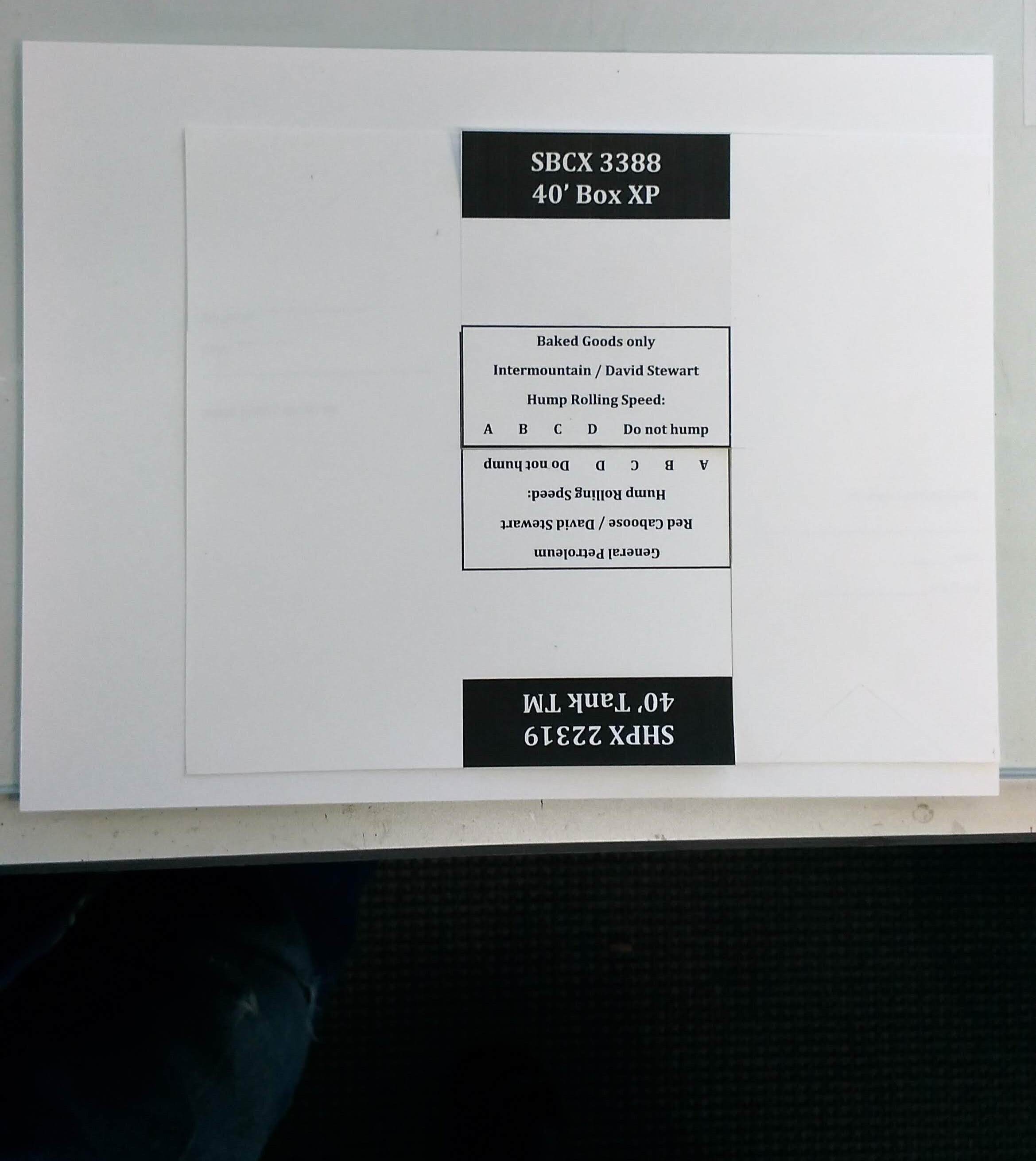

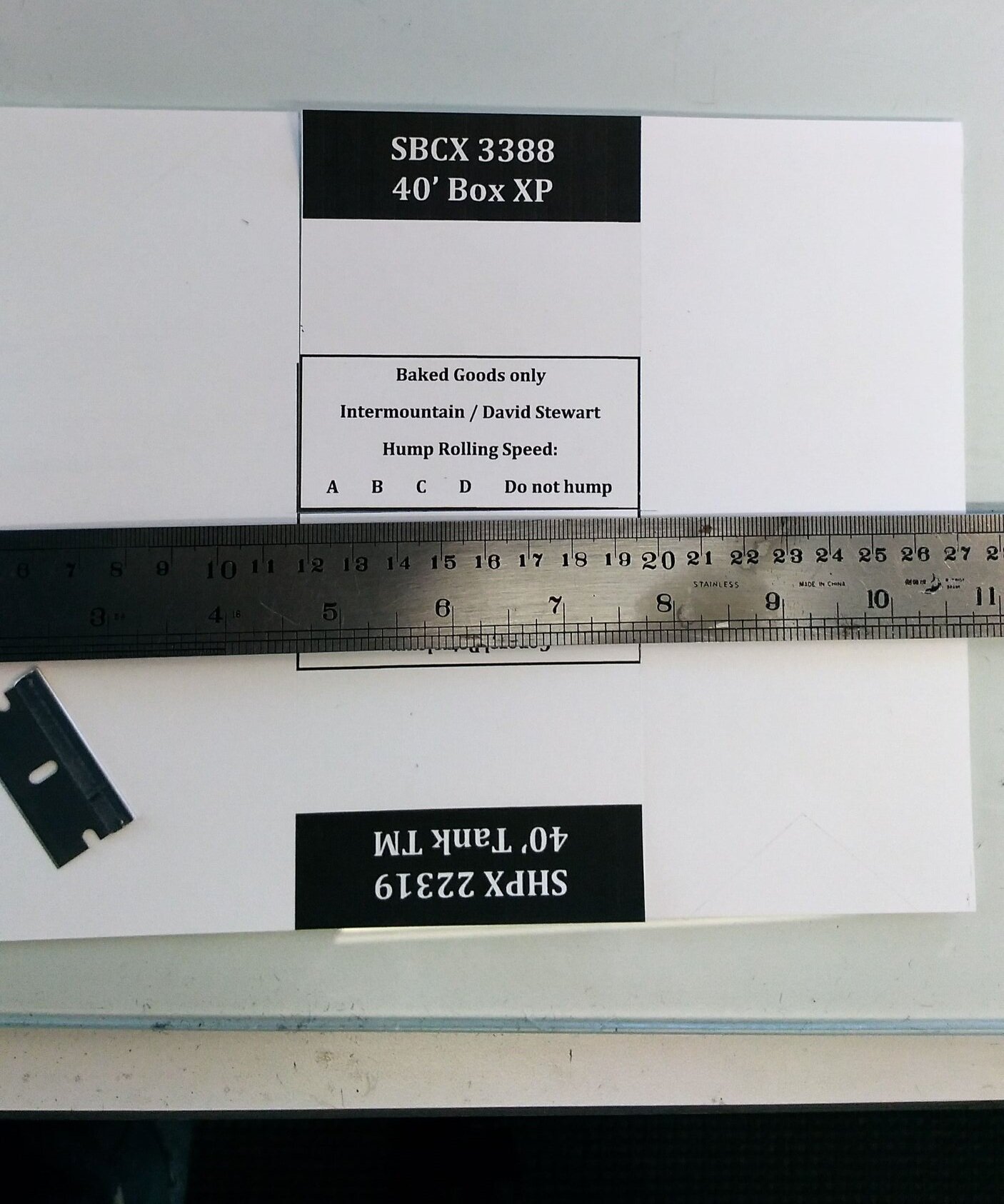

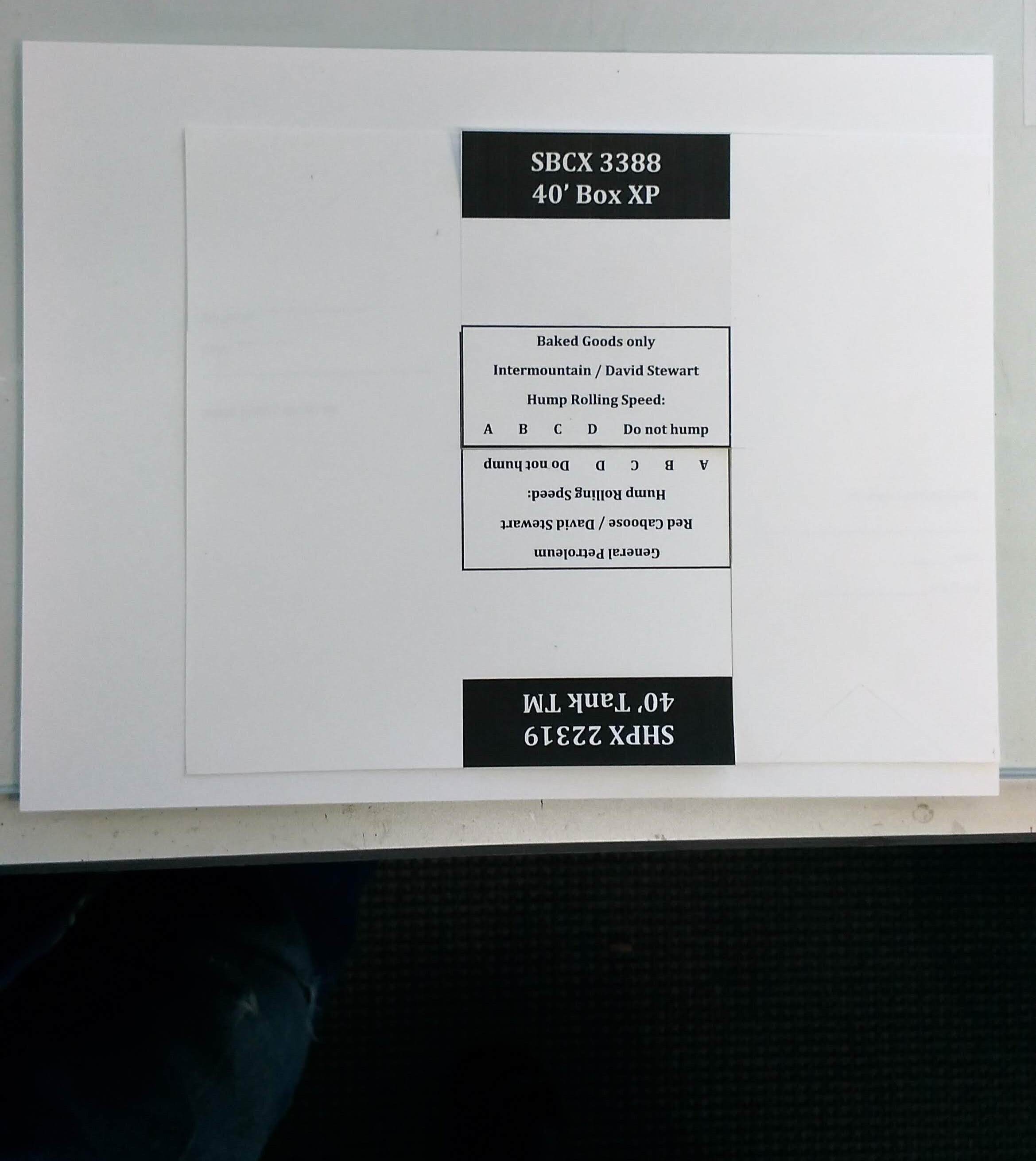

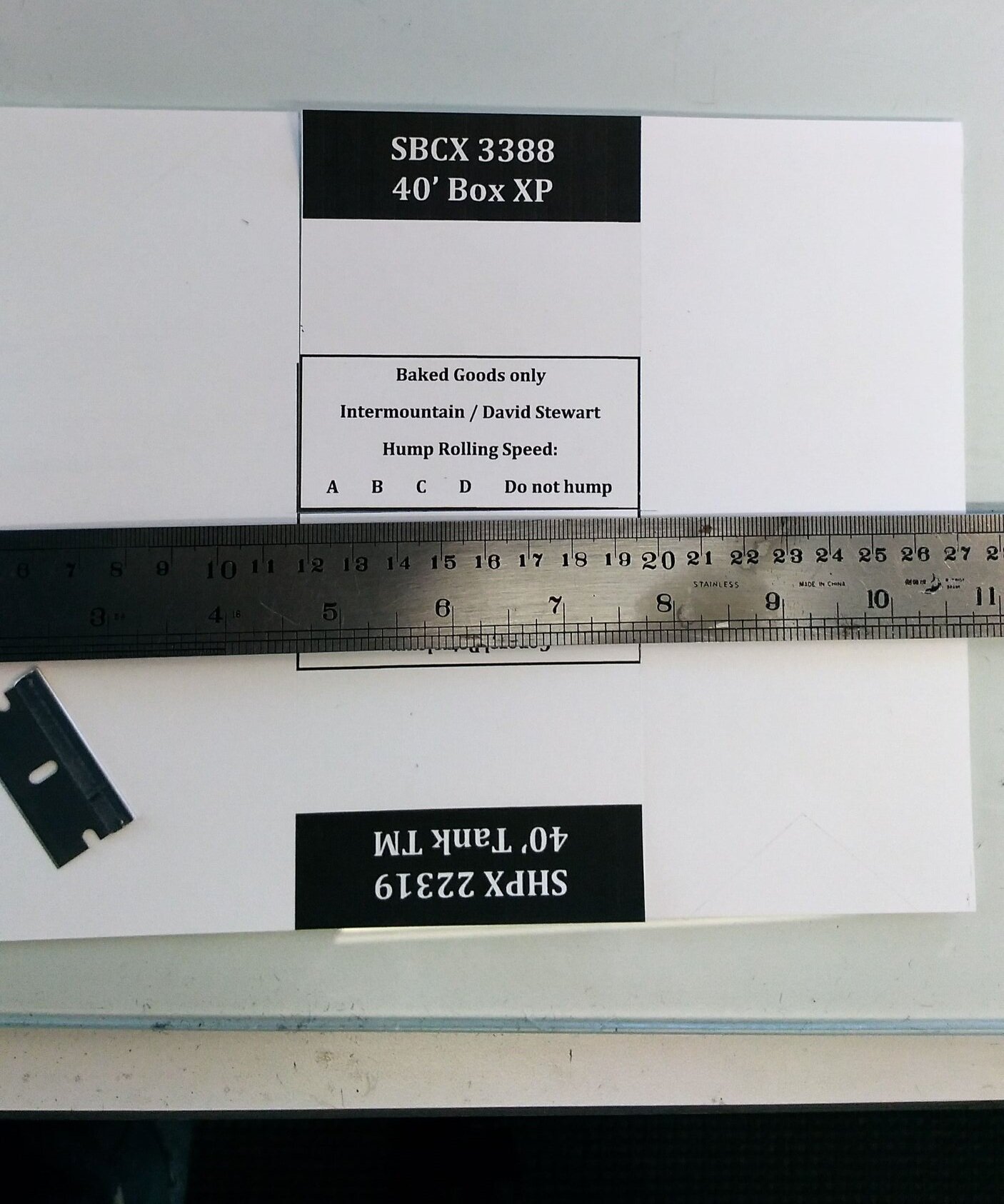

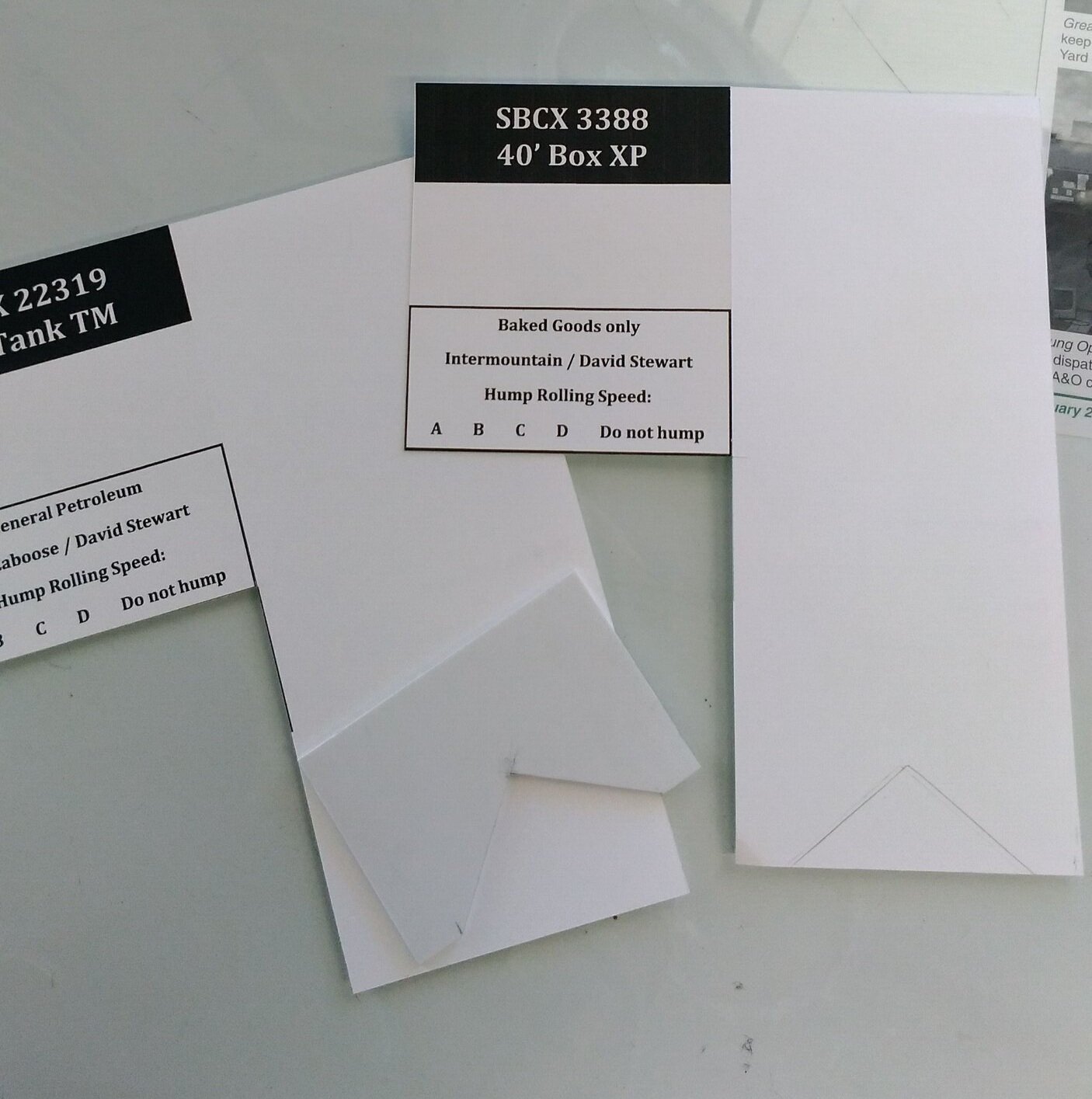

With the help of my awesome wife Katie, we printed car cards using Word. She was able to invert one below another such that a fold creates a pouch. The overall size of the cardstock car card is 3.25”x7.25”- Now THAT’S O Scale cards.

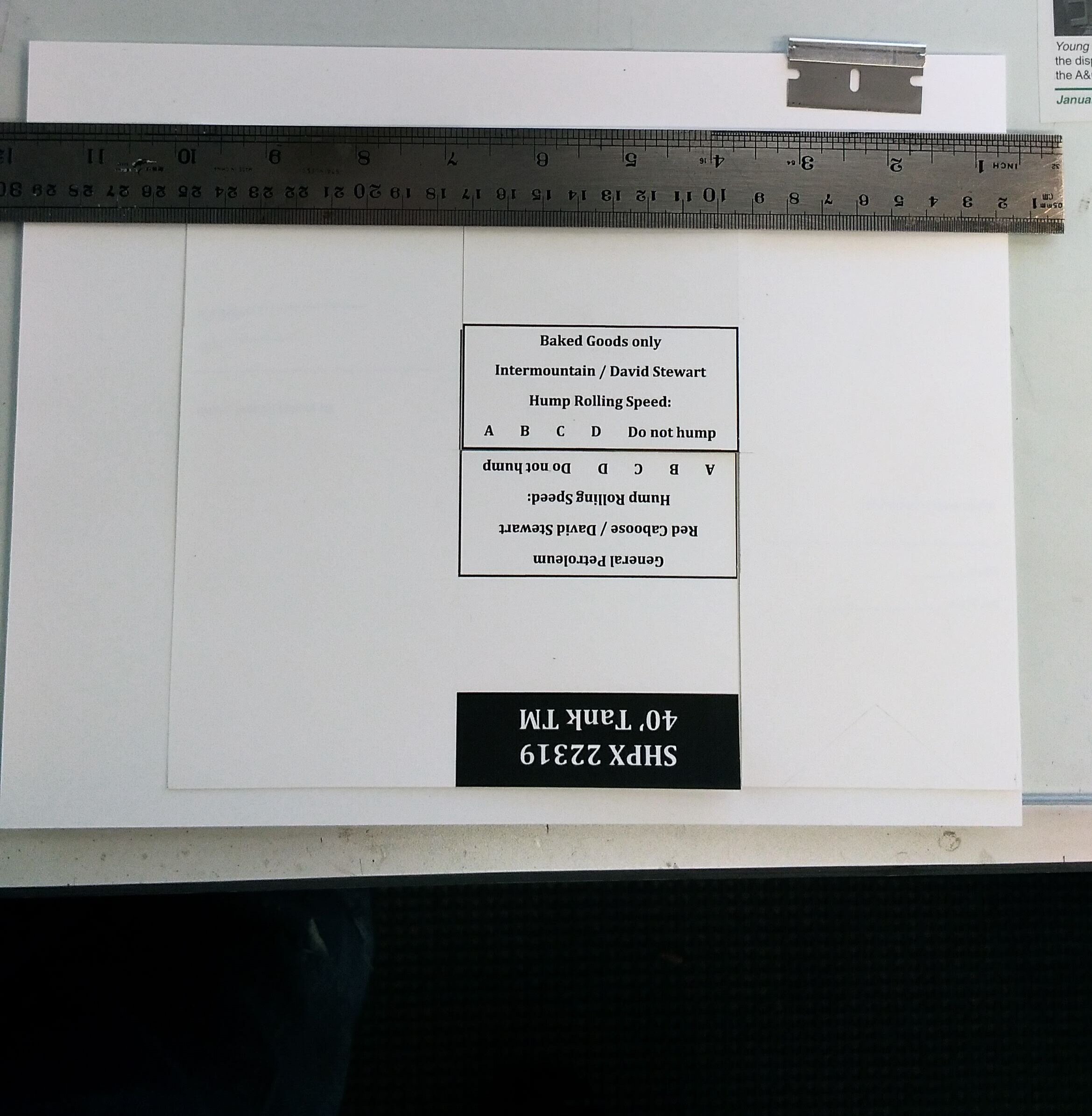

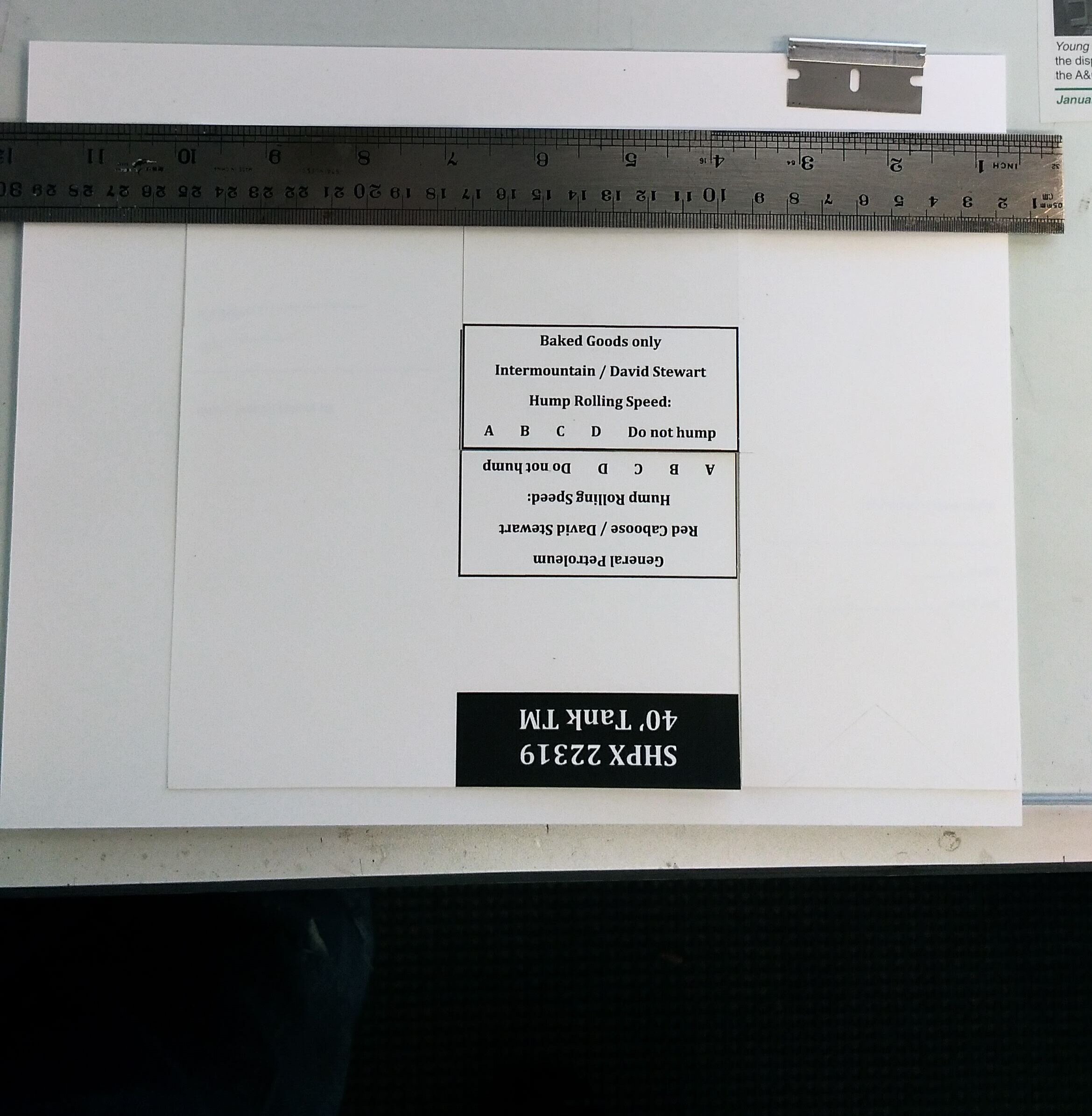

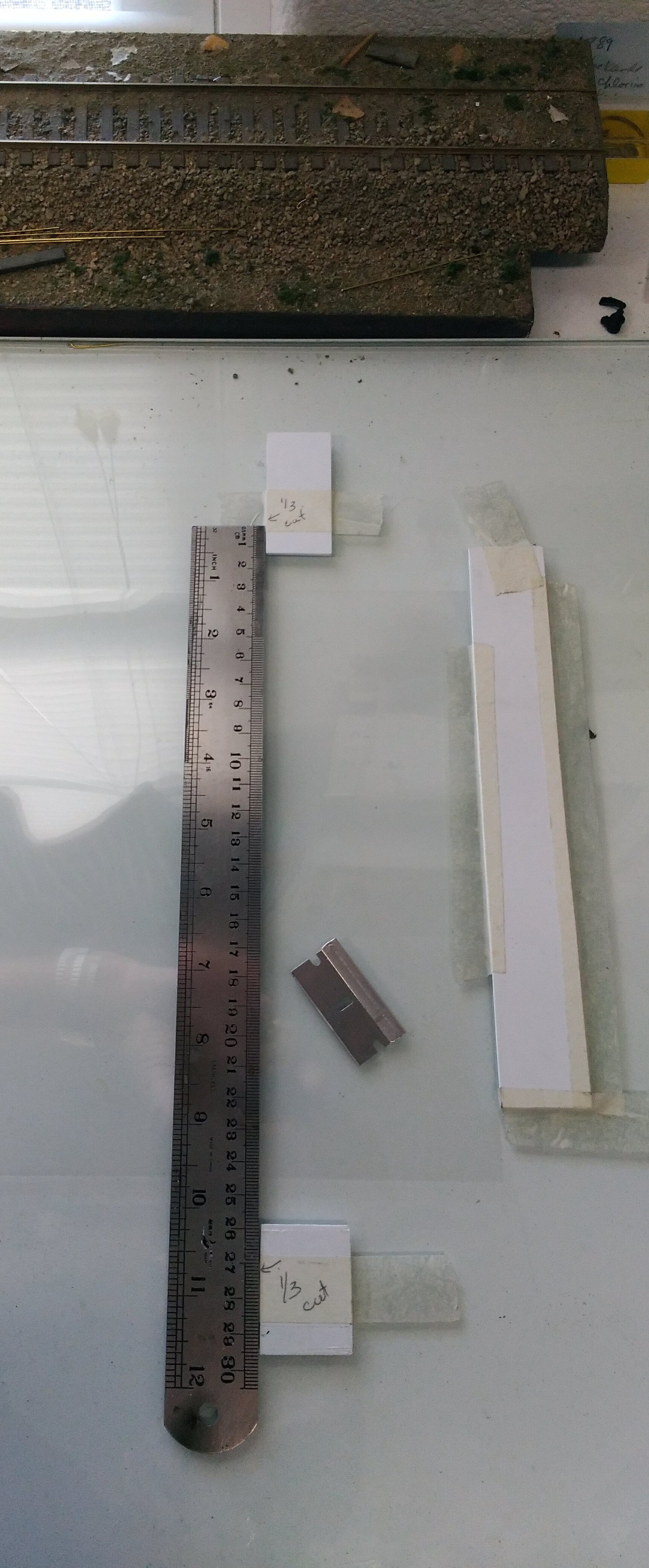

The 8.5x11” cardstock sheet is trimmed to size so each “wing” is equal to the width of the car card.

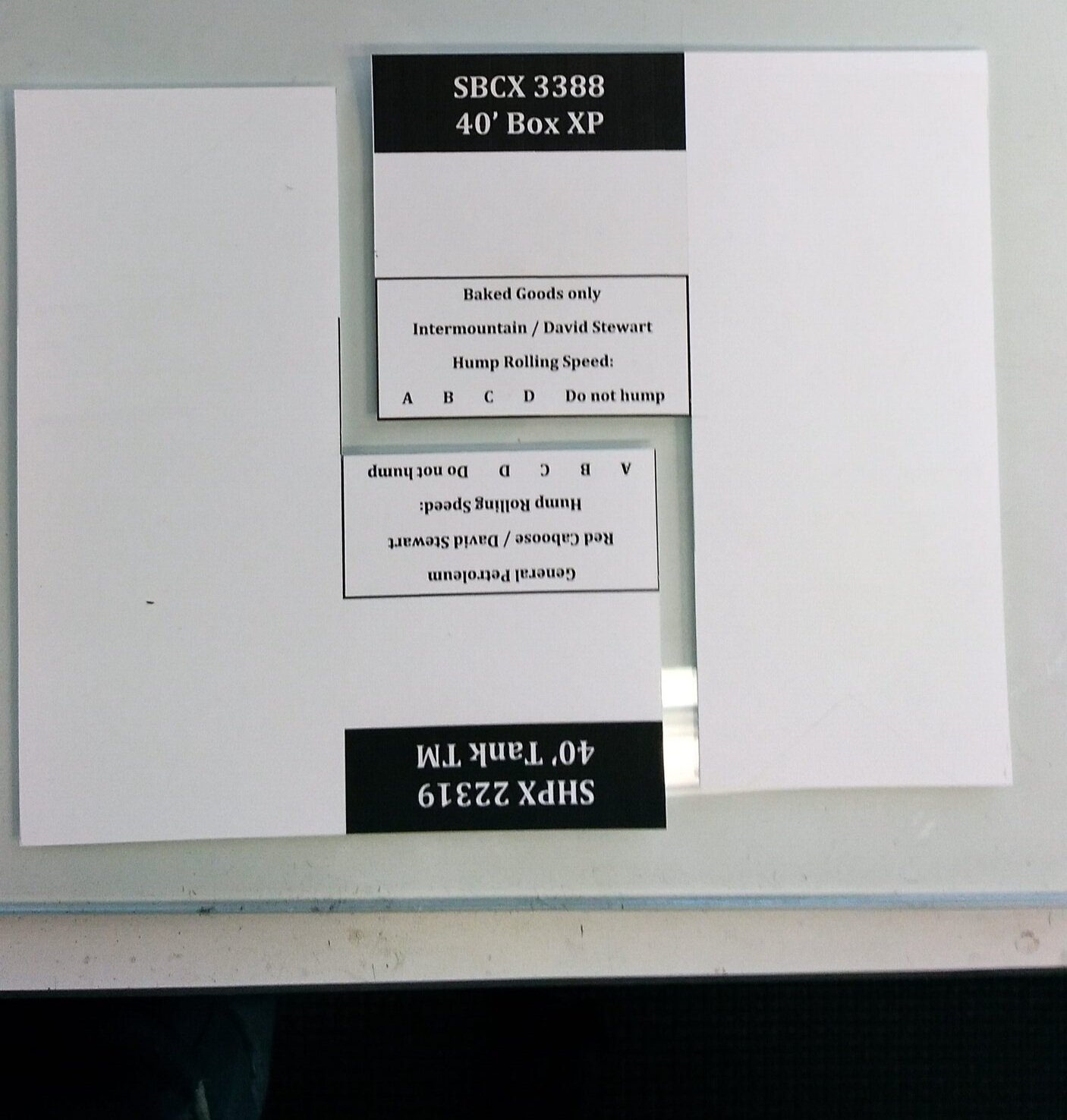

Next I cut down the left edge to the meeting line. Then I score lightly to the bottom of the cards. Next I cut across. Then lightly score top to middle, and clean cut to the bottom or down the other side. When done it looks like ….

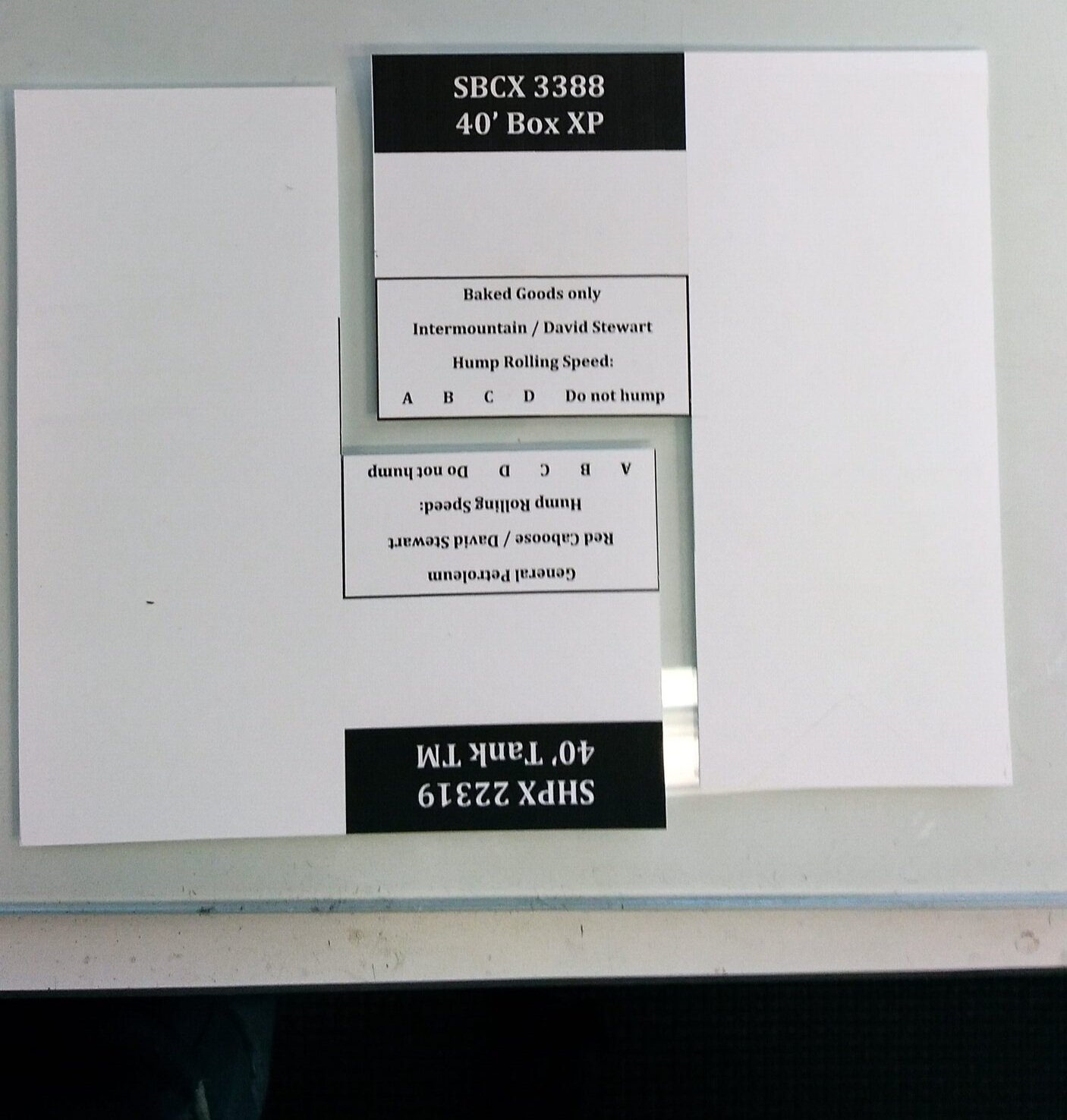

….this.

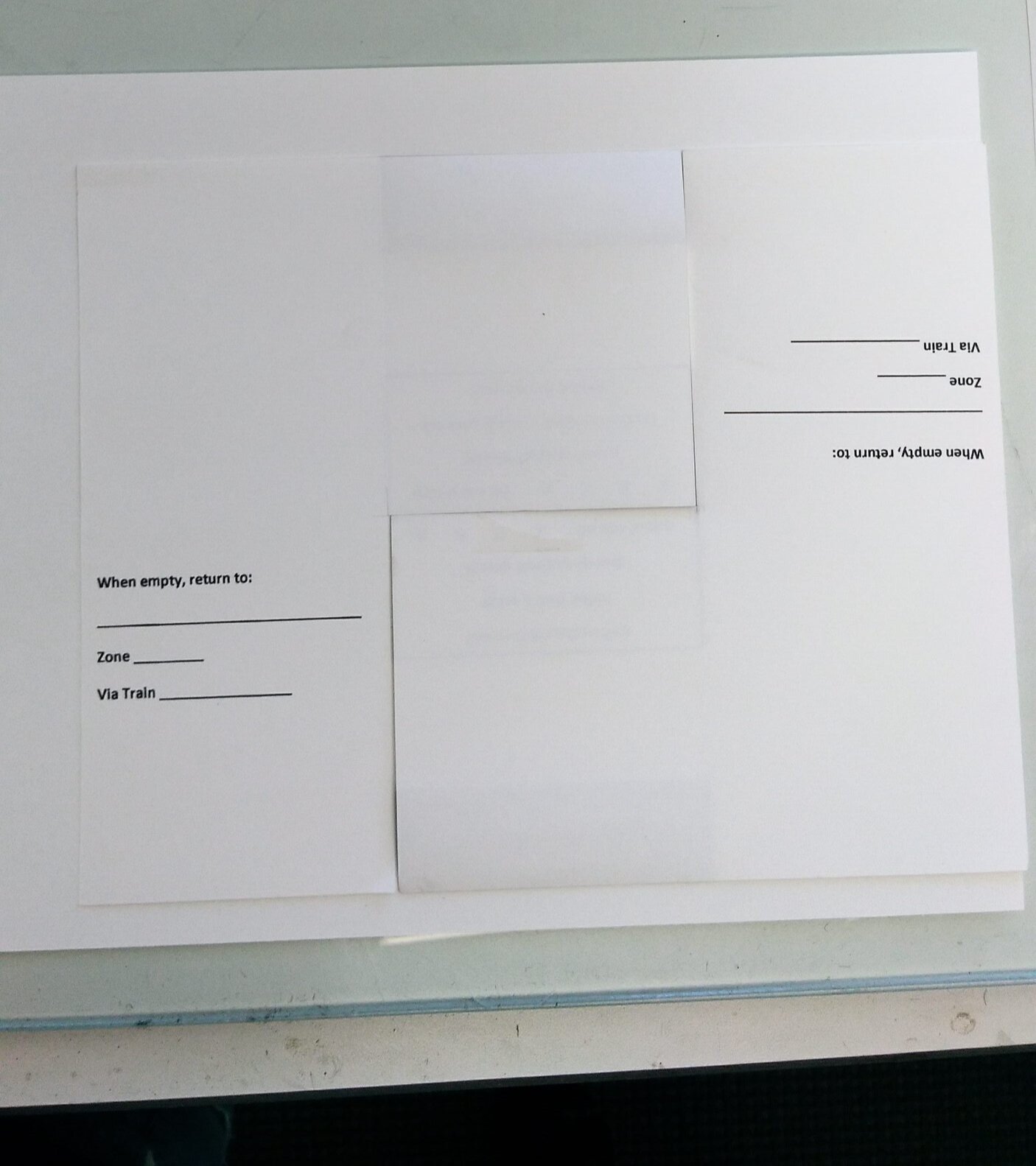

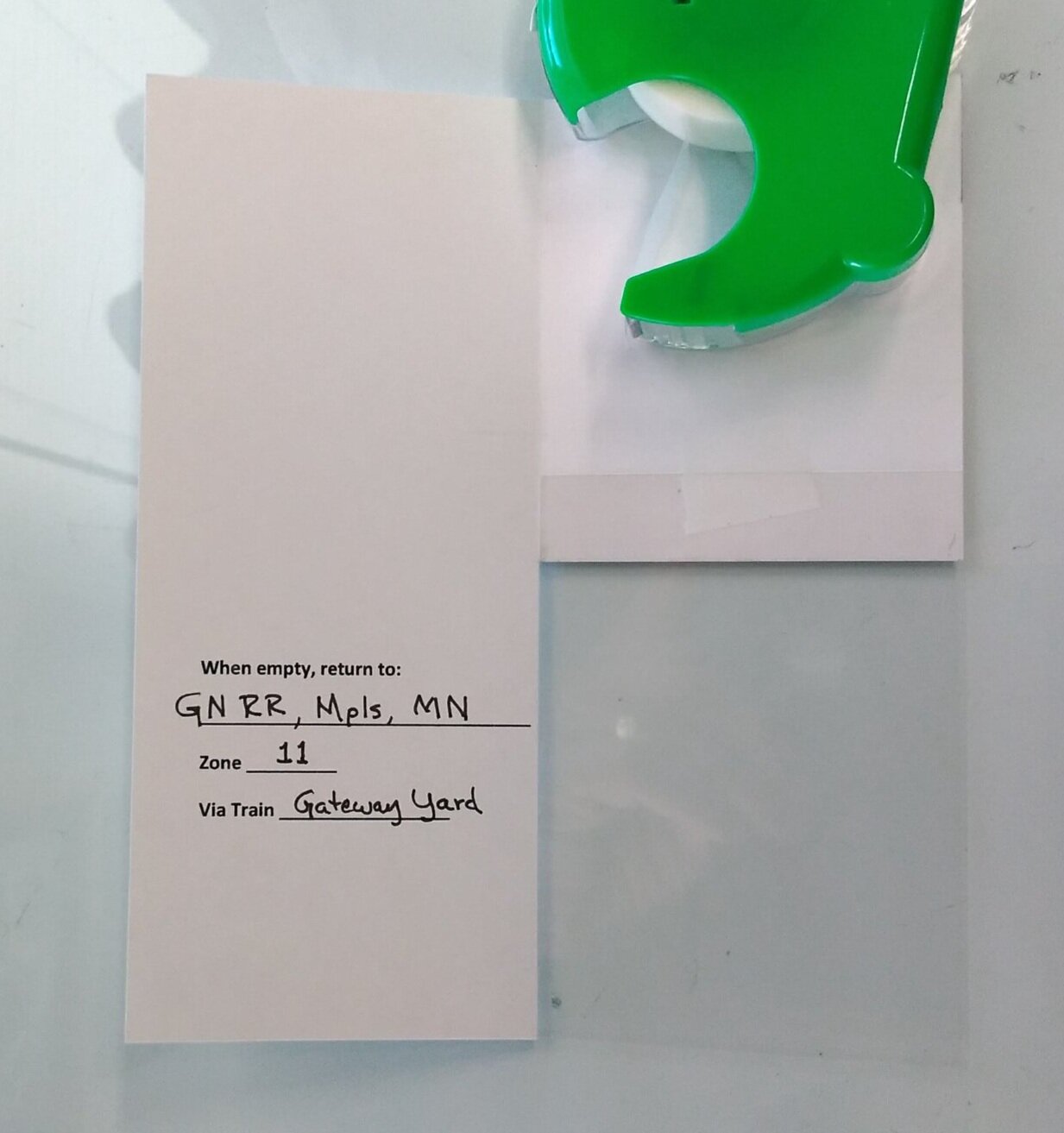

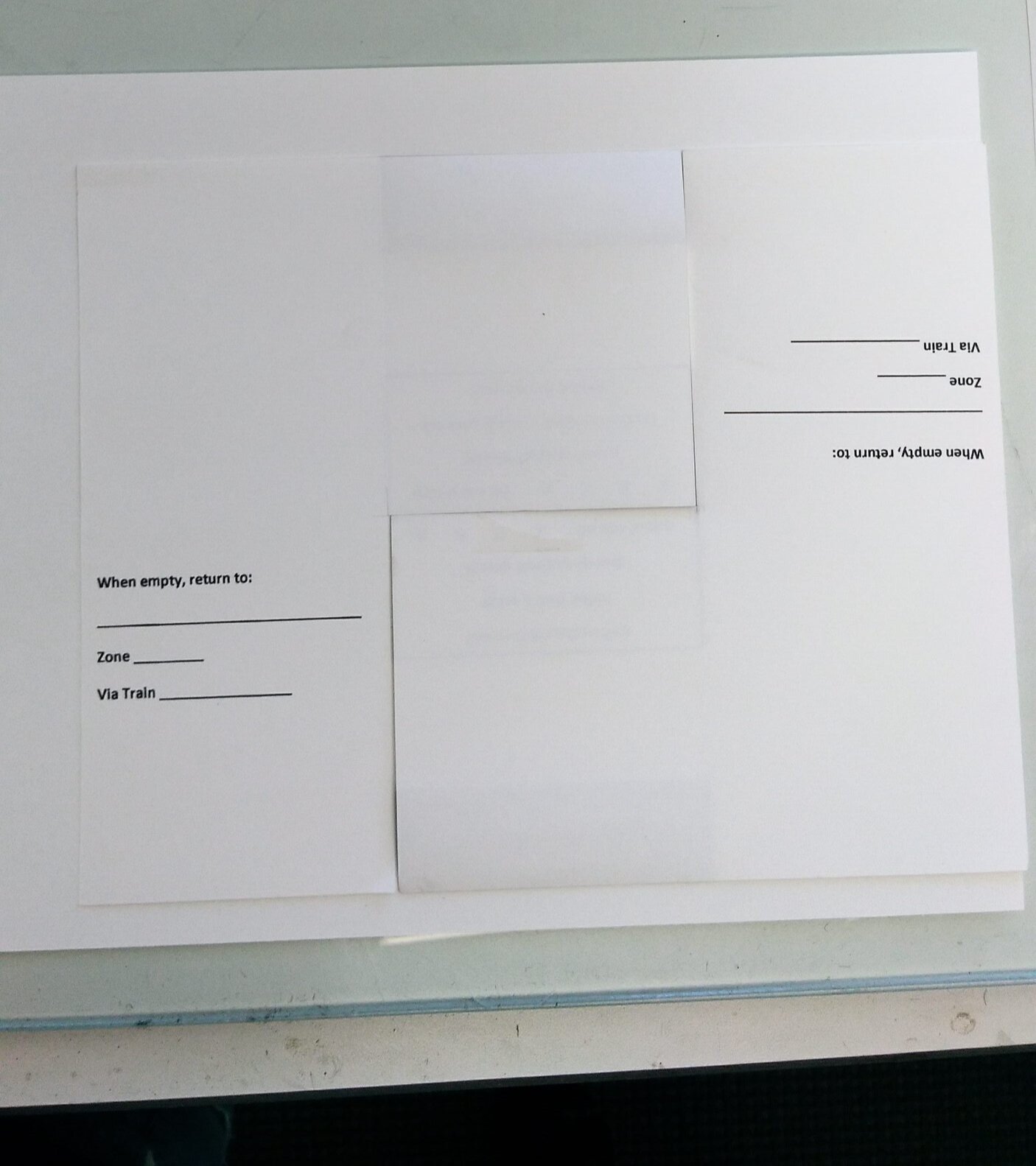

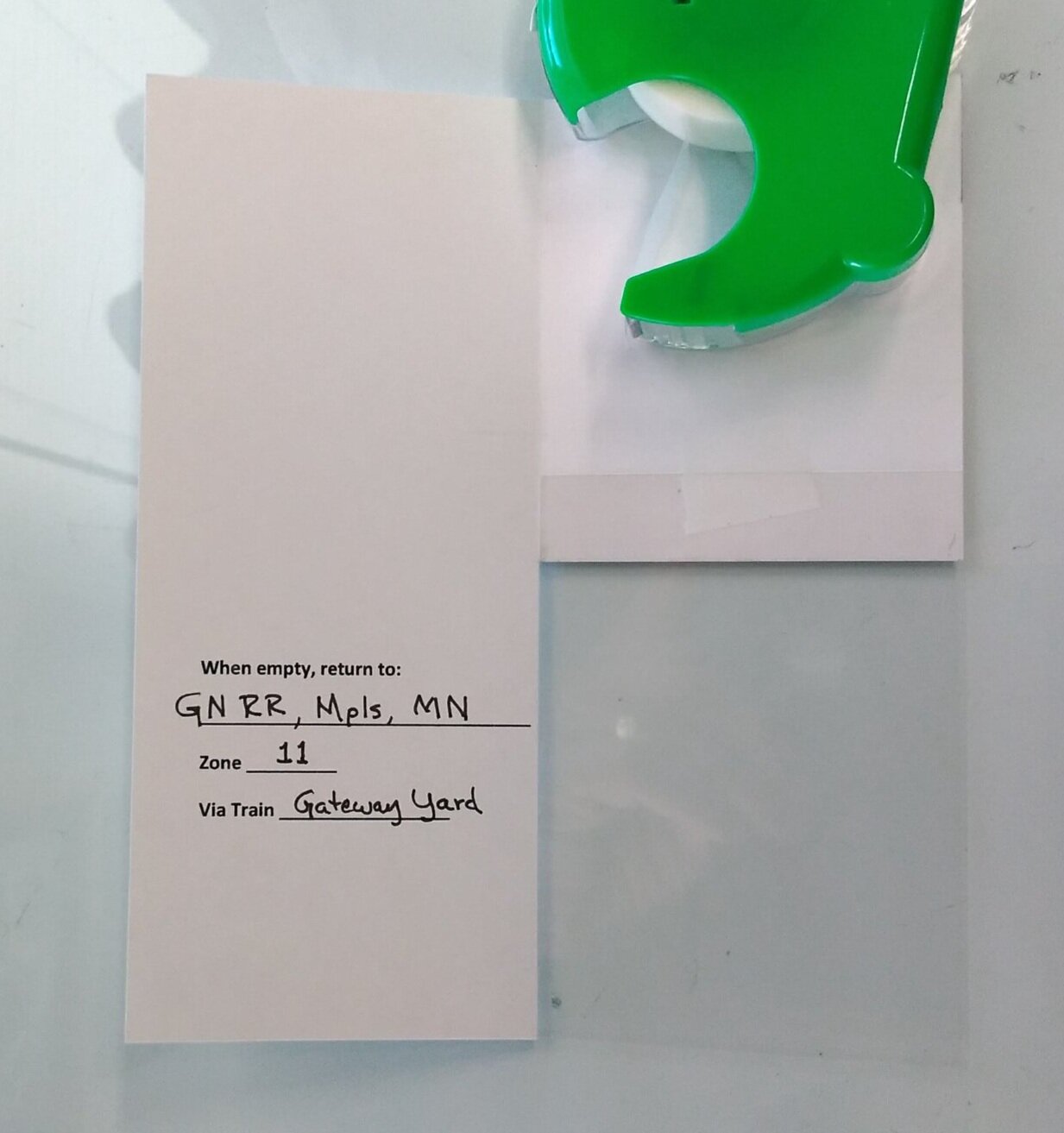

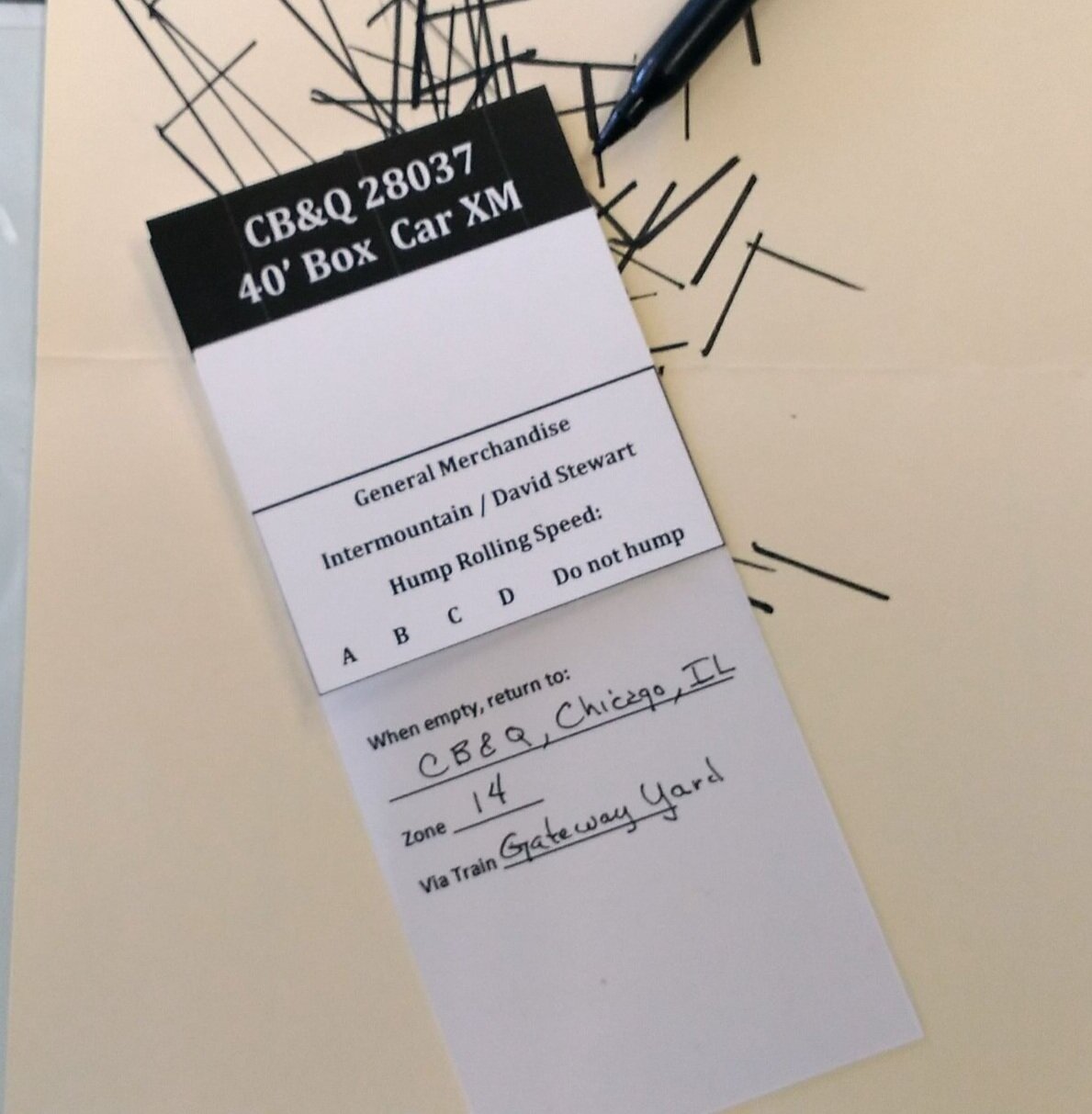

Unmentioned earlier is that we run the cards thru the printer a second time so as to print “When empty, return to:” etc. It takes a little fusswork at the outset to get the template set just right so the printed data comes out where you want it (thanks sweetheart)..

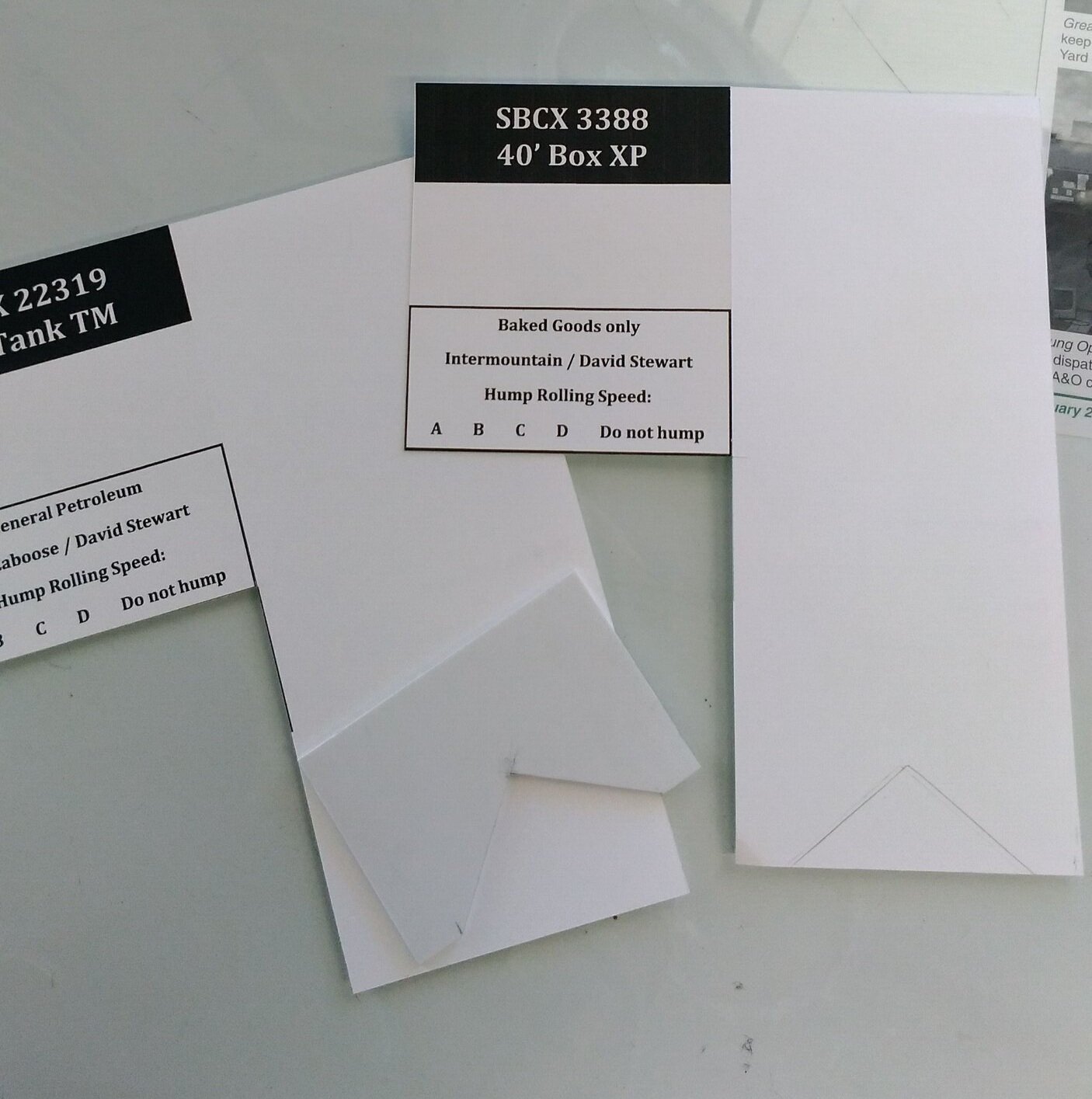

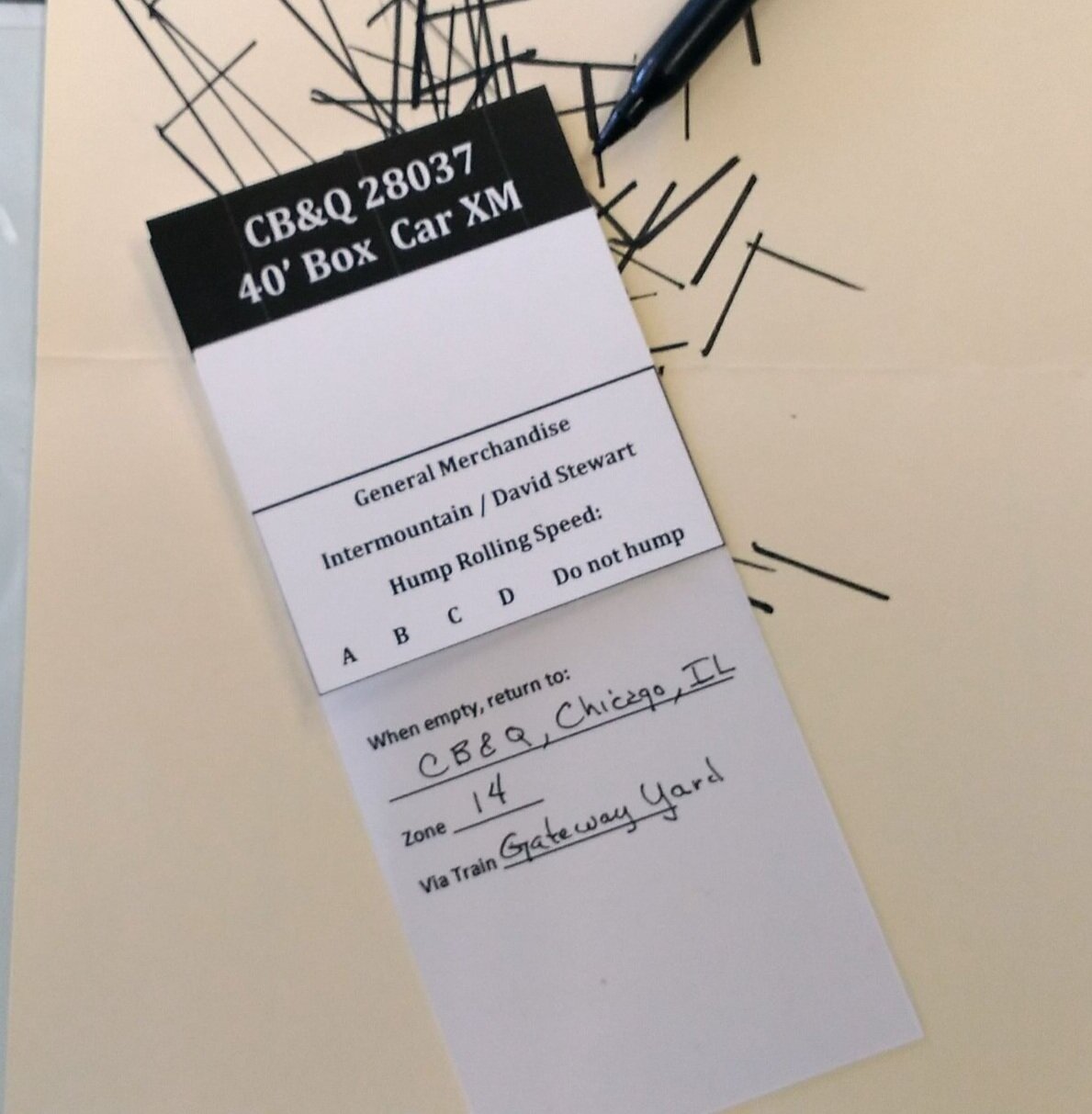

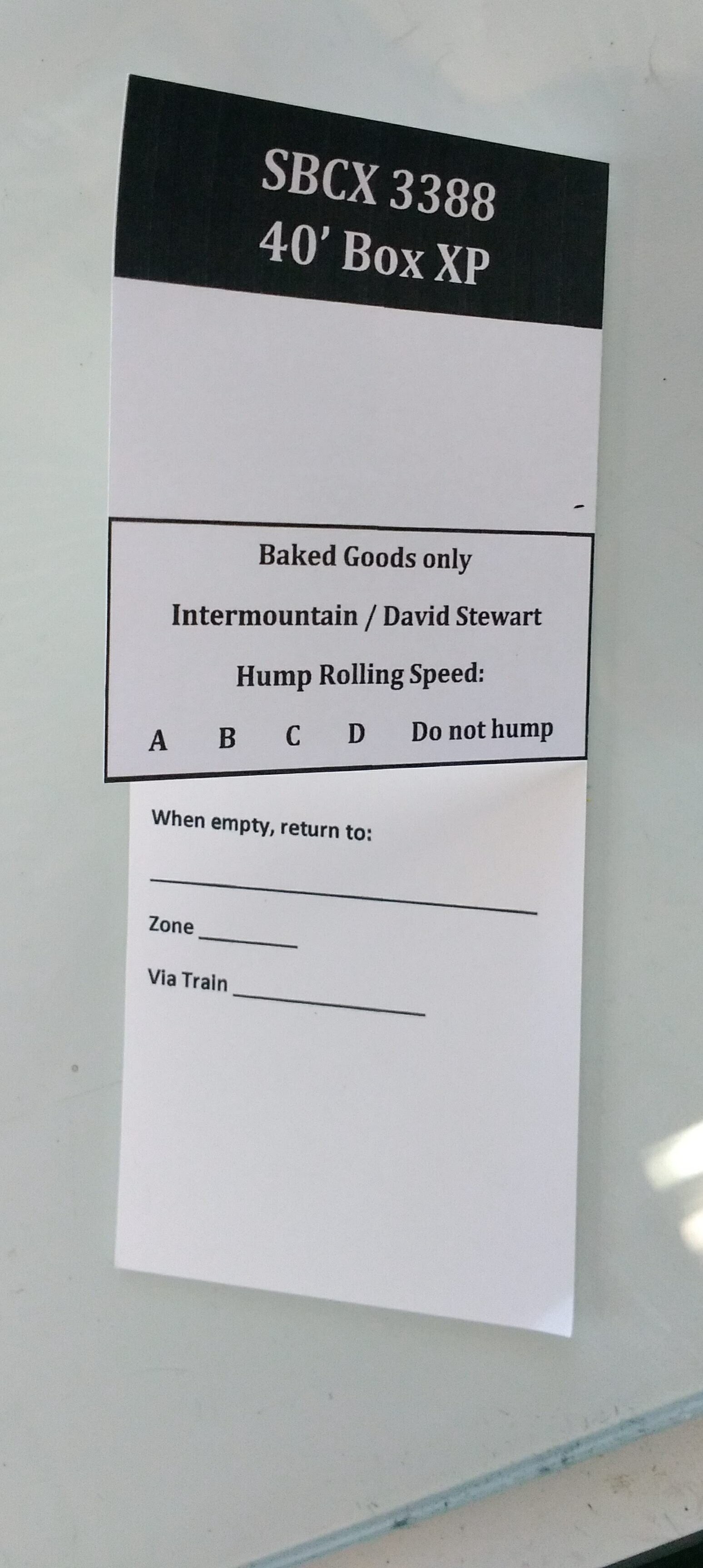

A nearly completed card. The lightly scored edge from the previous slide makes the fold clean and true. Almost time for the clear, see-through front of the pouch.

But first- A styrene template “V” is placed on the back of the card and a pencil line drawn in the “V”. This will later facilitate cutting out the wedge making easier insertion and removal of the waybill.

A packet of Transparency Film from Office Depot is next.

I taped some styrene guide stops to my glass-topped work bench after figuring out how to get the most number of pouch squares out of a 8.5x11” sheet of transparency film. While the width is the same as the car card, the height is more than the visible area. See next slide-

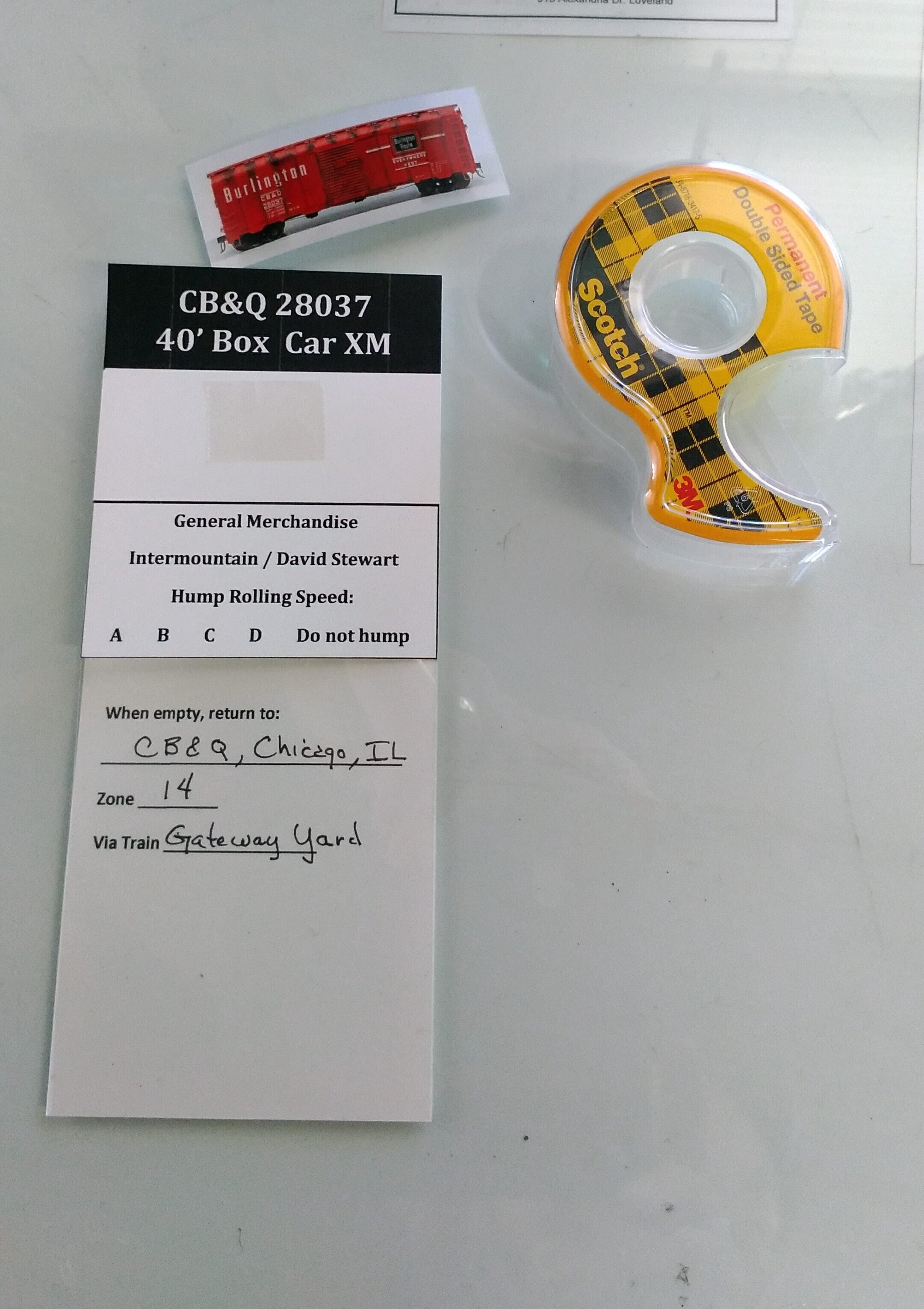

Here the transparency rectangle is taped in place. Even with the bottom edge of the car card and extending up above the viewing area- and then held in place with magic tape.

At this point I fill-in the MTY Return data. This is GN Airslide Flour covered hopper. Tony Koester’s “Realistic Model RR Op” pg. 55 shows GN RR is Zone 11 for return of MTYS. More on this on the Operating Positions page.

If you’re also a bit of a perfectionist, now is the time add some black to the edges of the data box as may be needed, etc. Whew. Now I feel better.

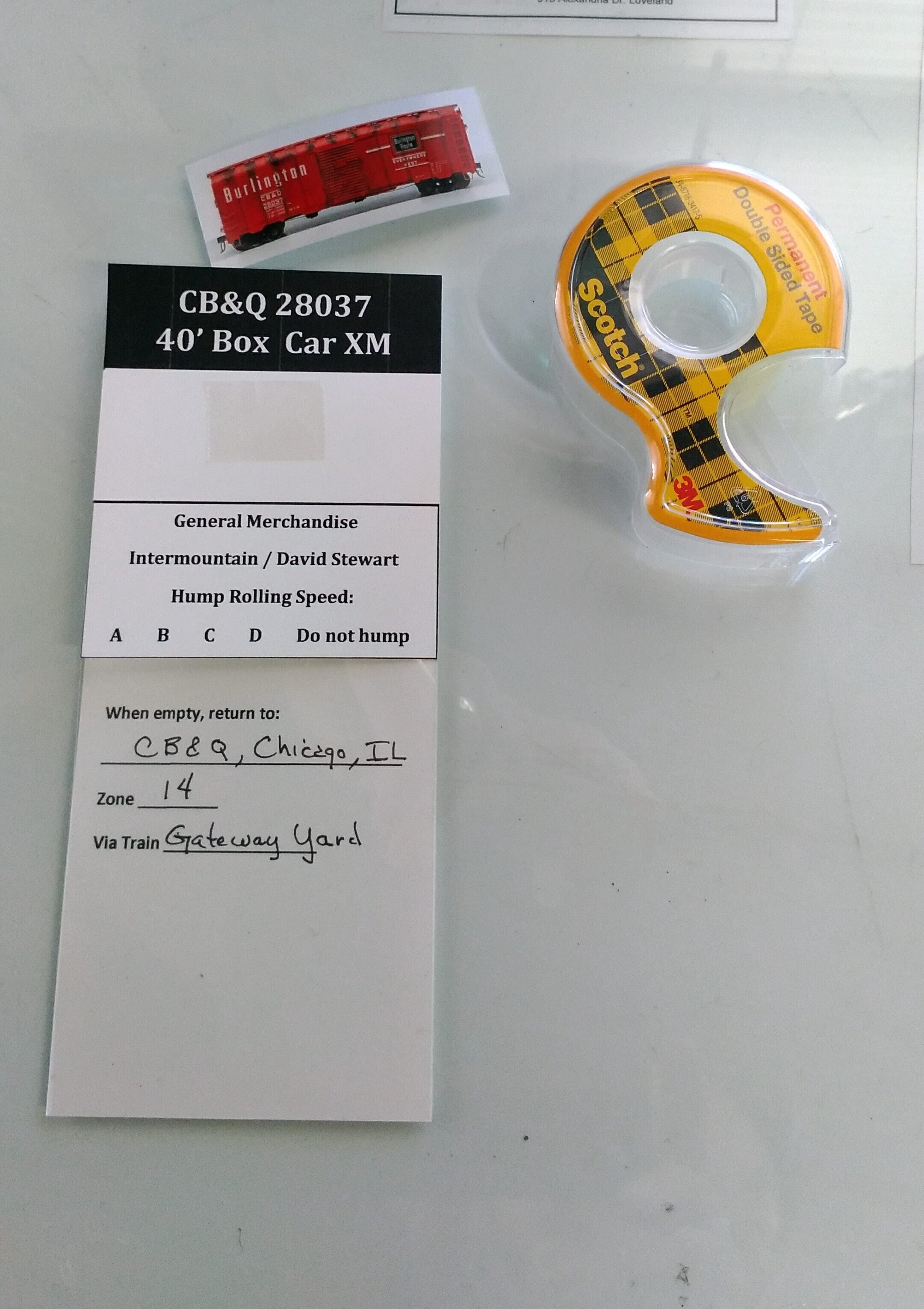

Time to add the trimmed car picture to the card. I use double stick tape for this.

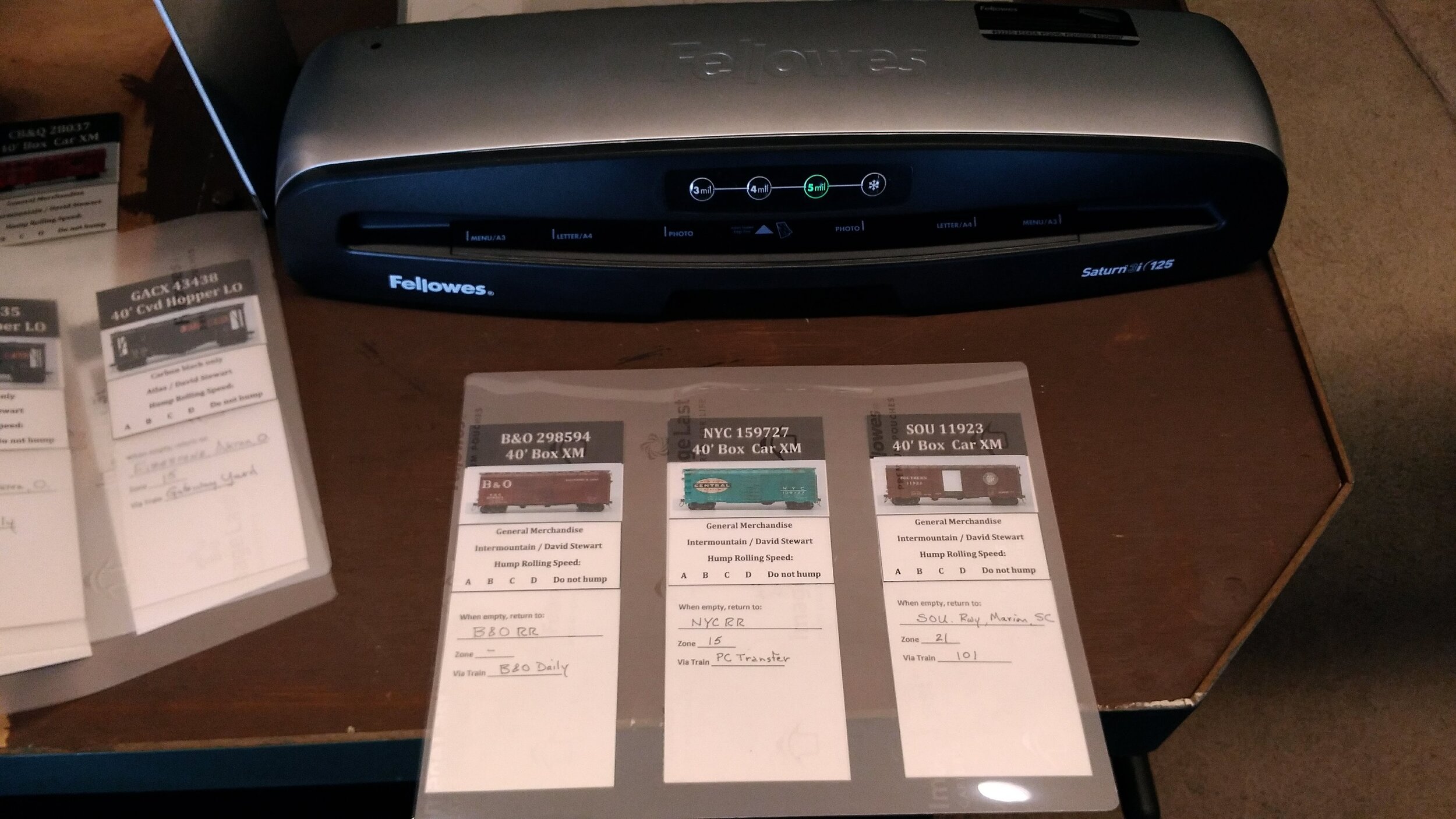

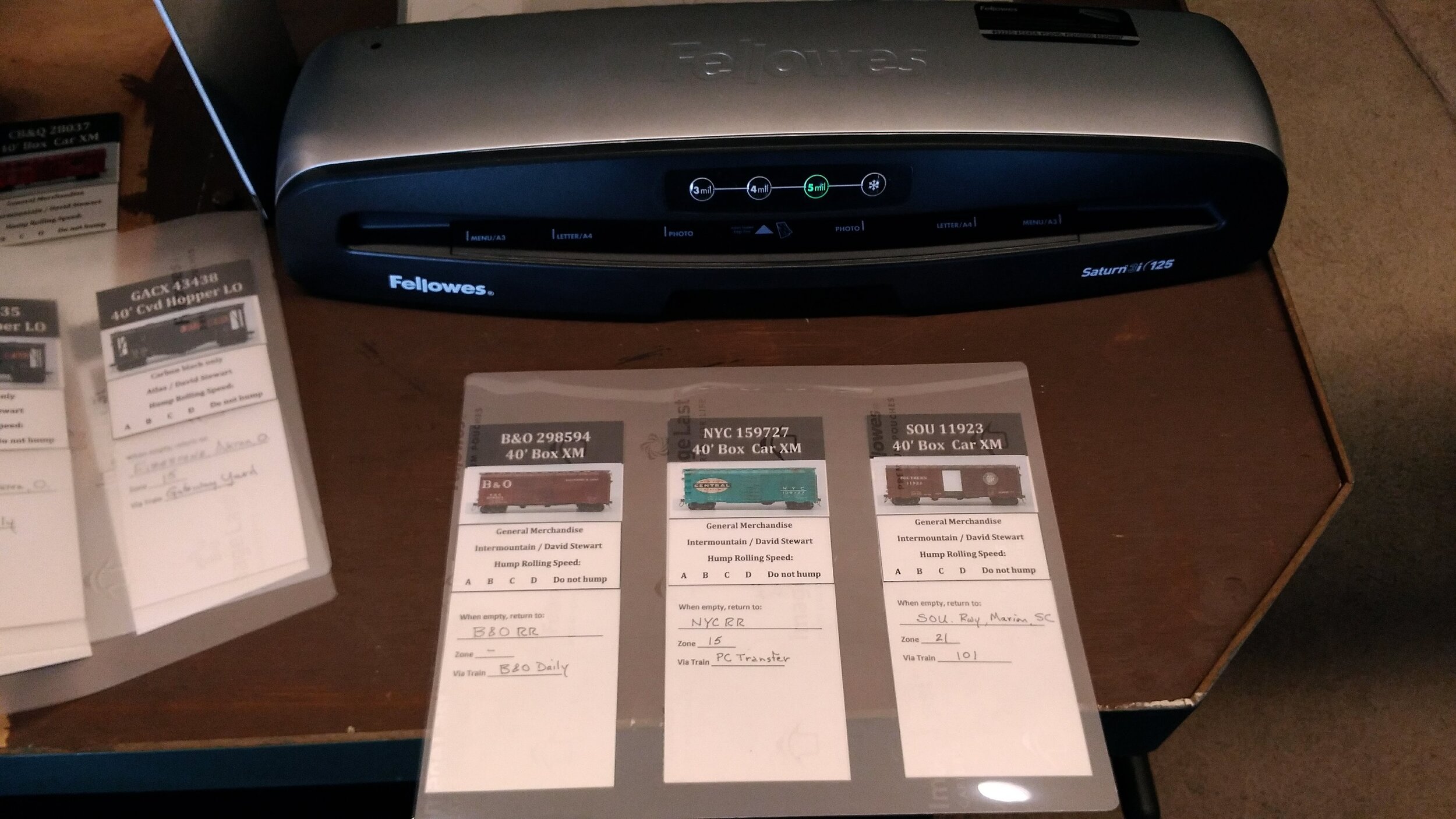

Lamination time. I bought a Fellow’s Laminator just for the A&O’s many laminated items. I also buy bulk packs online of 5 mil 12x17” laminating pouches. I run the pouches thru two times, inverting the second time. Wait; cool. Now turn 90 degrees and repeat. I’ve had virtually no separation of the pouches from use. When it does occur, just run the card thru a couple times and it reseals.

Cut the car card flush along the bottom edge, then leaving an 1/8” or so for sealing, trim the card. Then flip over and opening the newly formed/sealed pouch, put one leg of a pair of scissors into the pouch and cut out the “V” on the cardstock (NOT the transparency film). It’s now easy to insert a waybill into the pouch of the car card.

The cars with their matching cards start to fill up every available spot.

No more room!!

Hey Bob, I found some more!

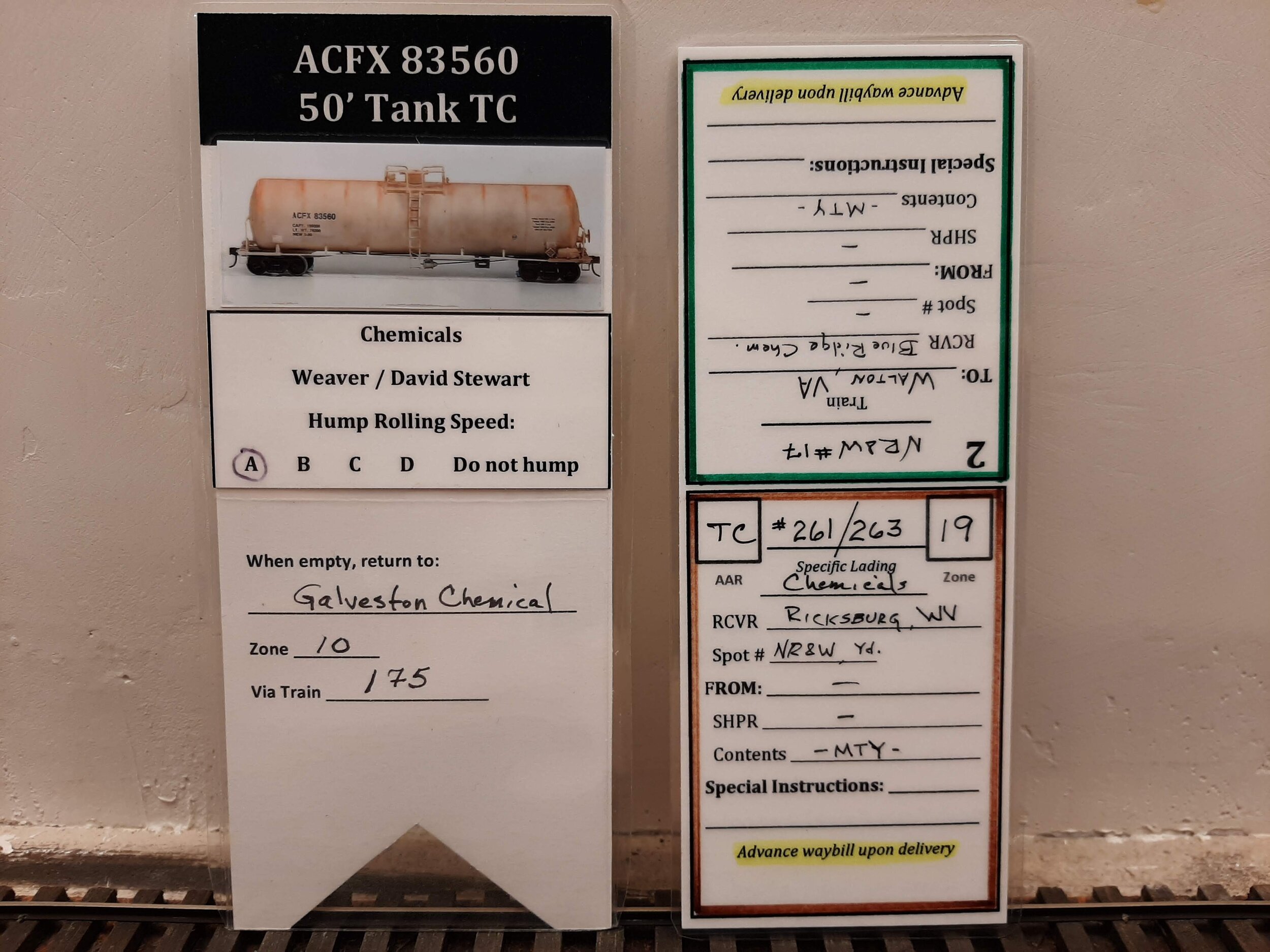

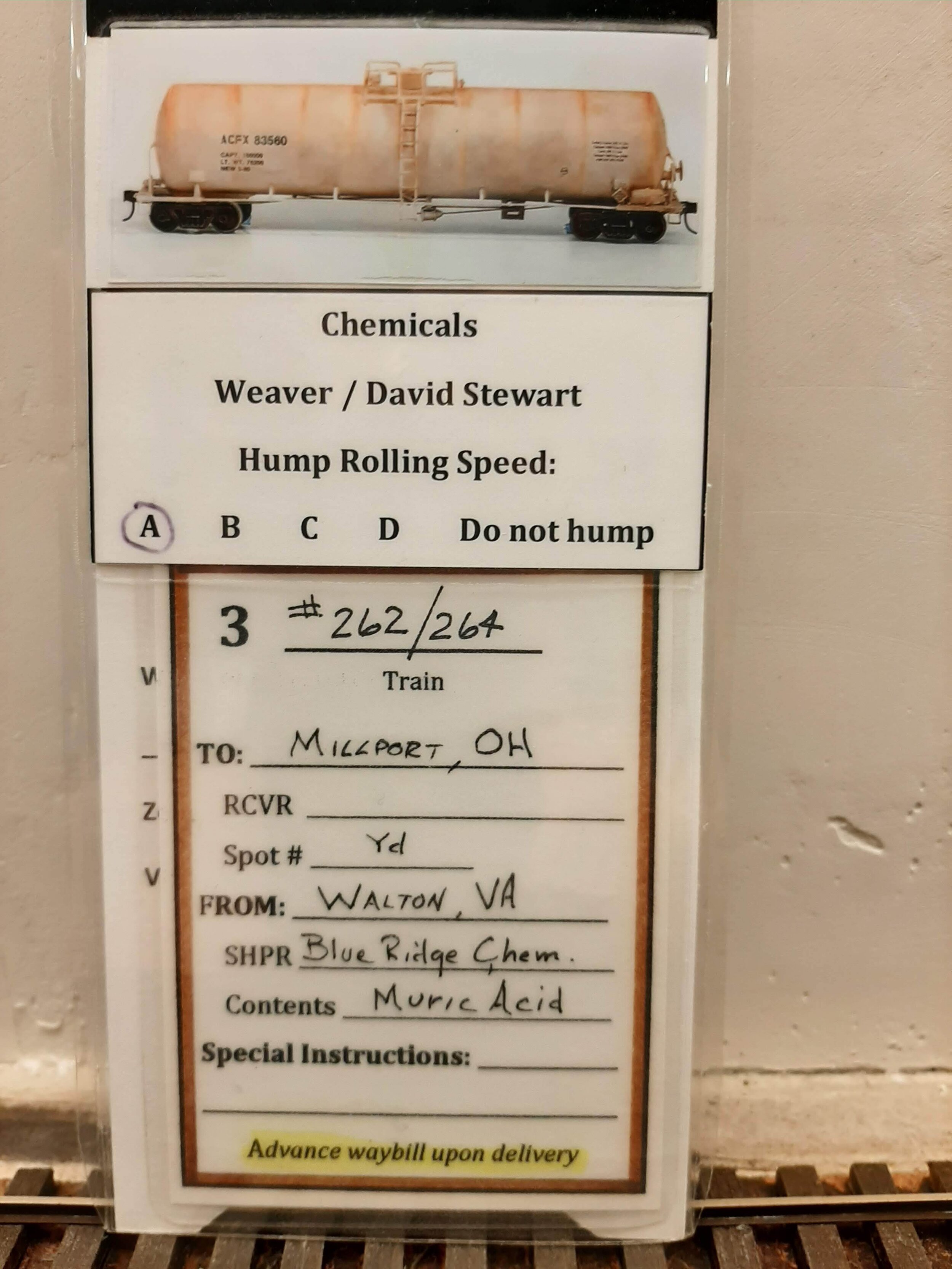

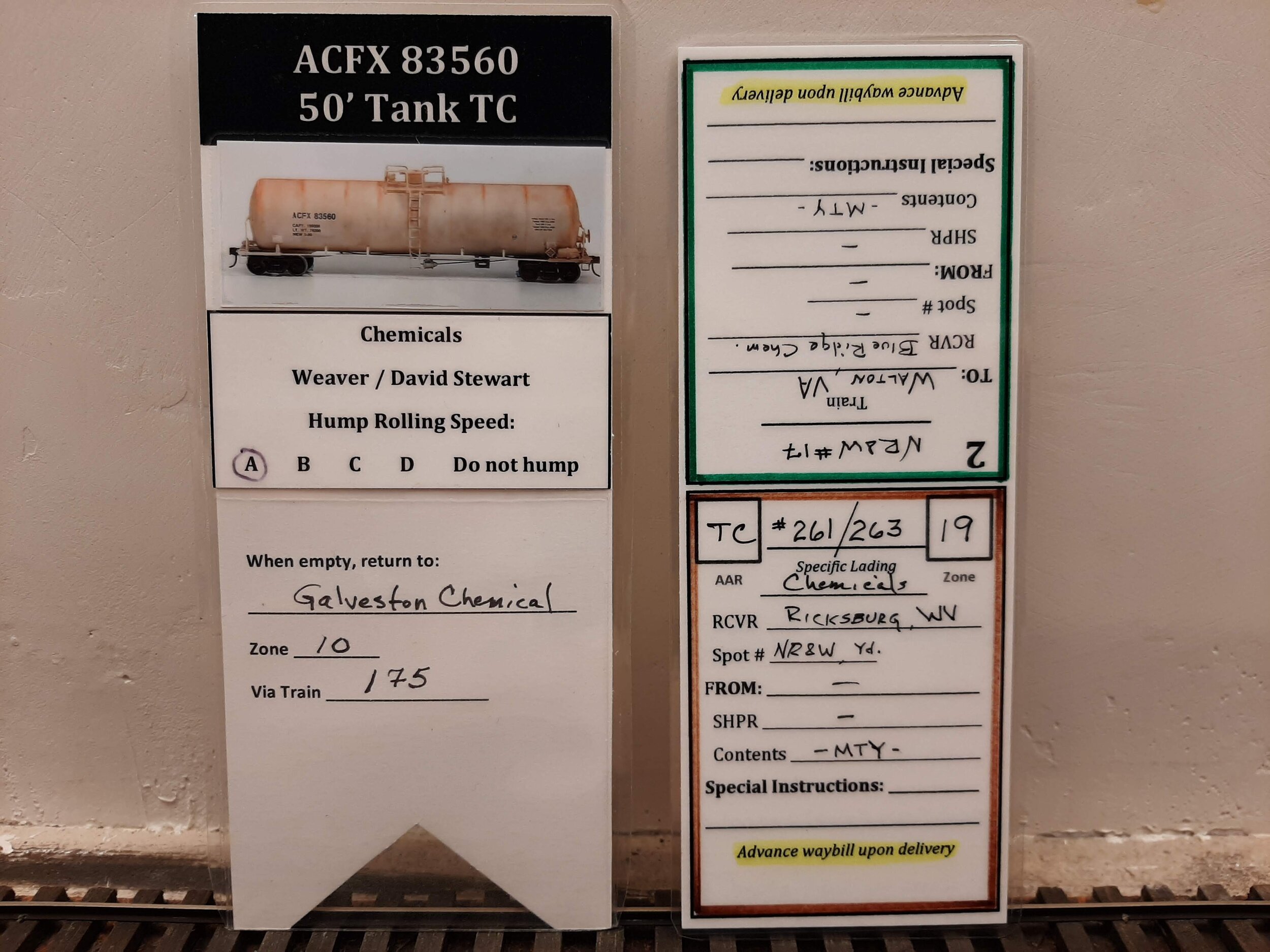

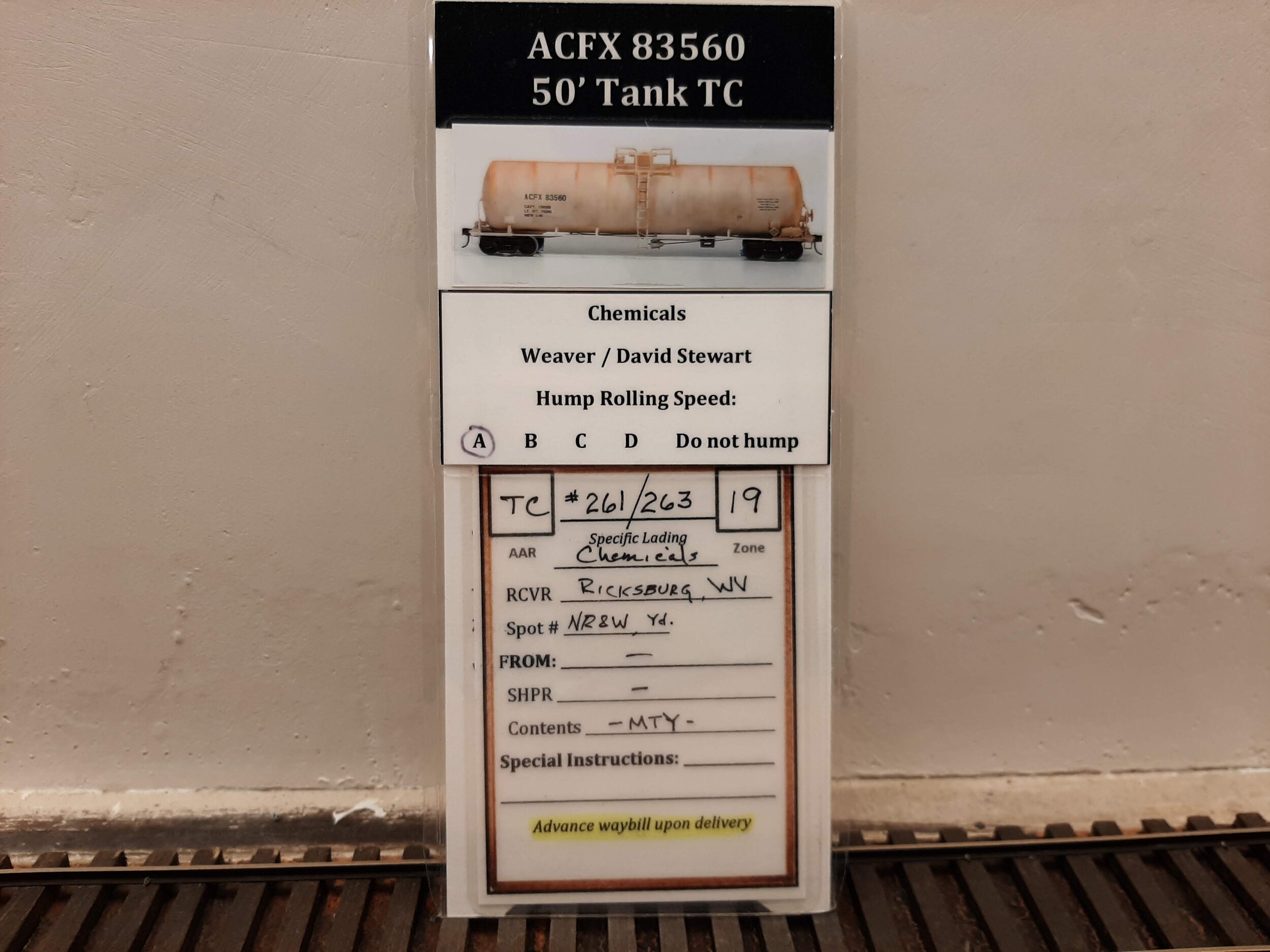

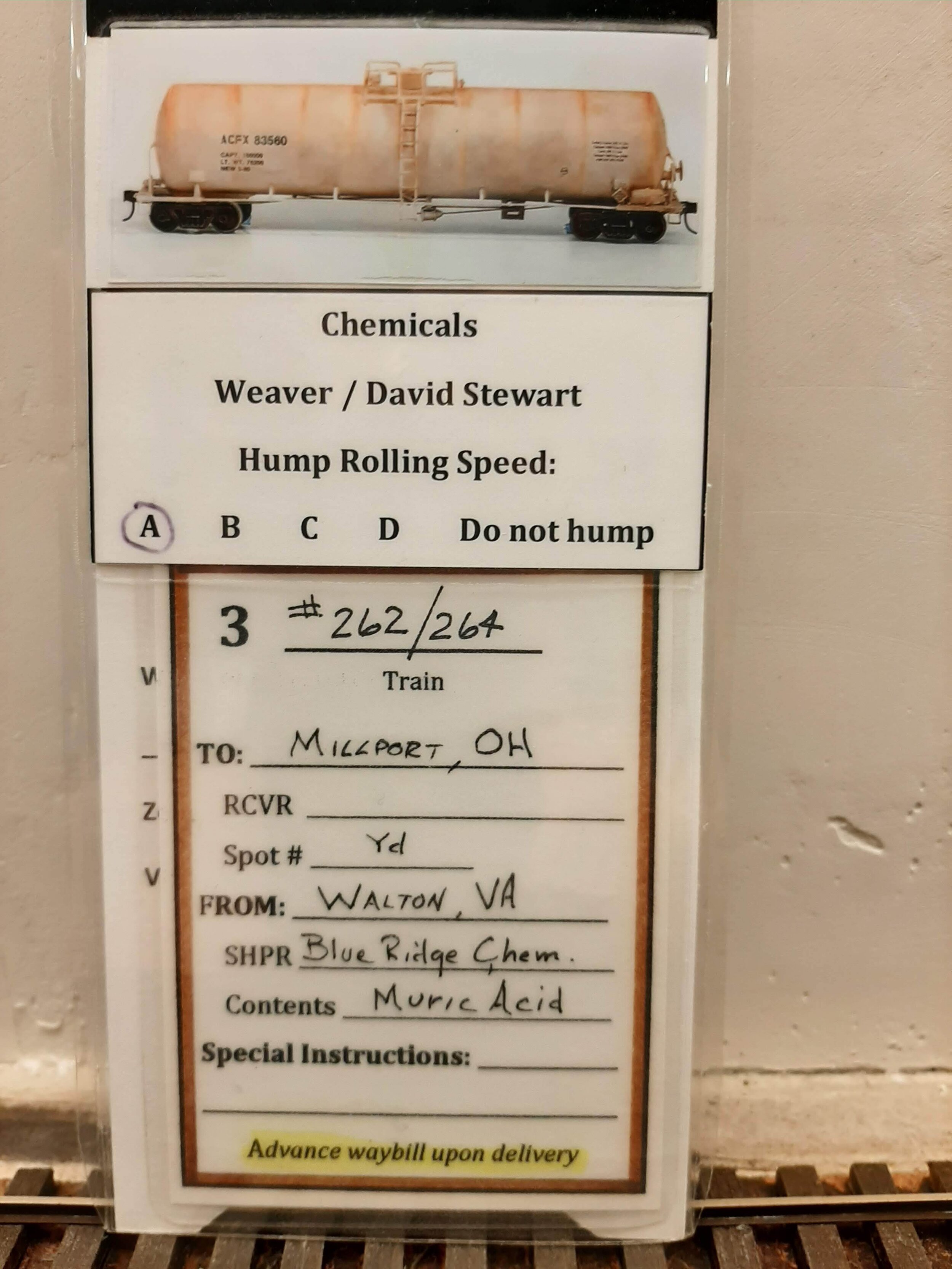

ACFX 83560 with it’s matching card, ready for service. By having MTY car routing car data, I essentially gain a 5th waybill destination. More on how that is handled on the Operating Positions page.

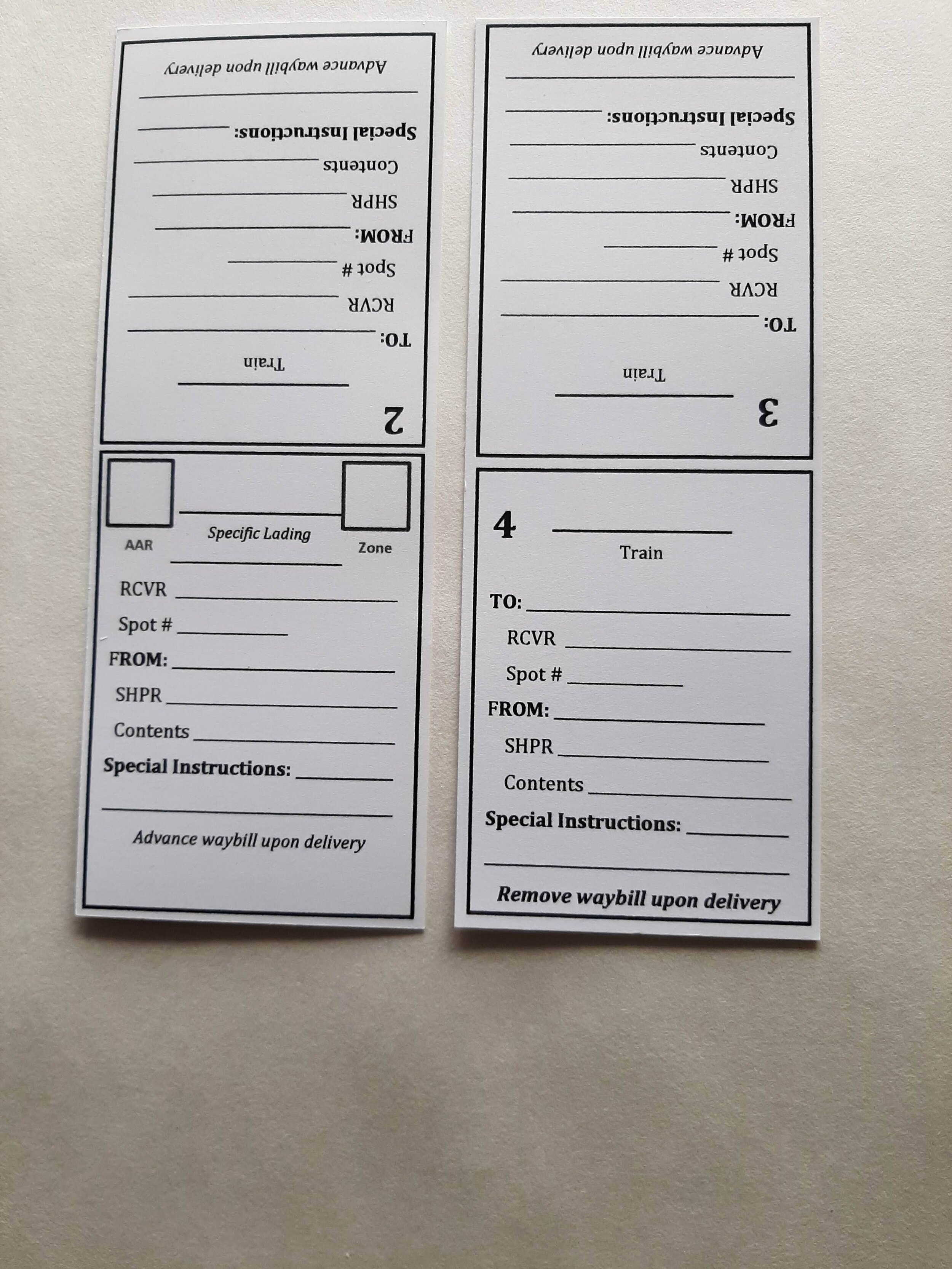

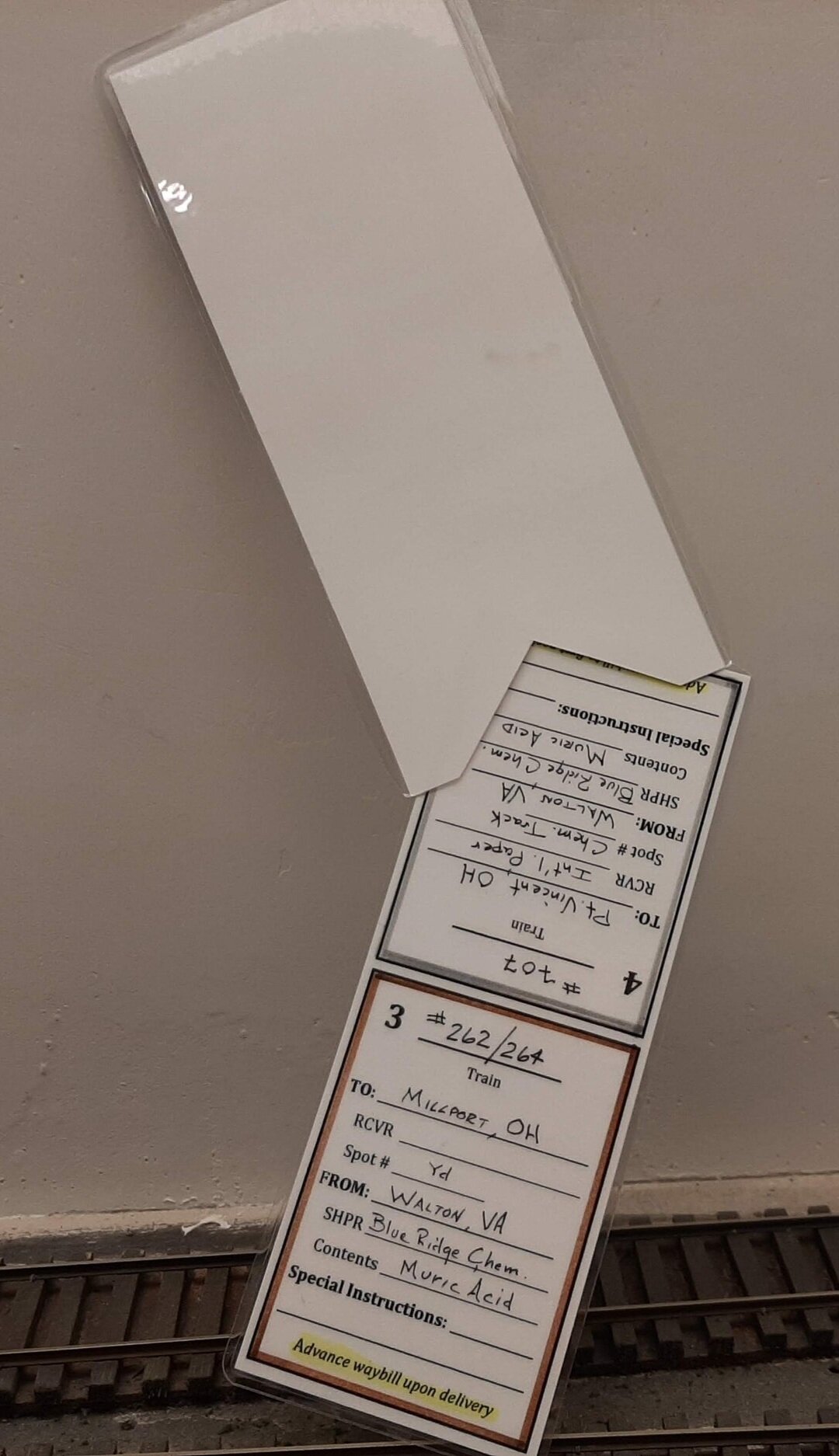

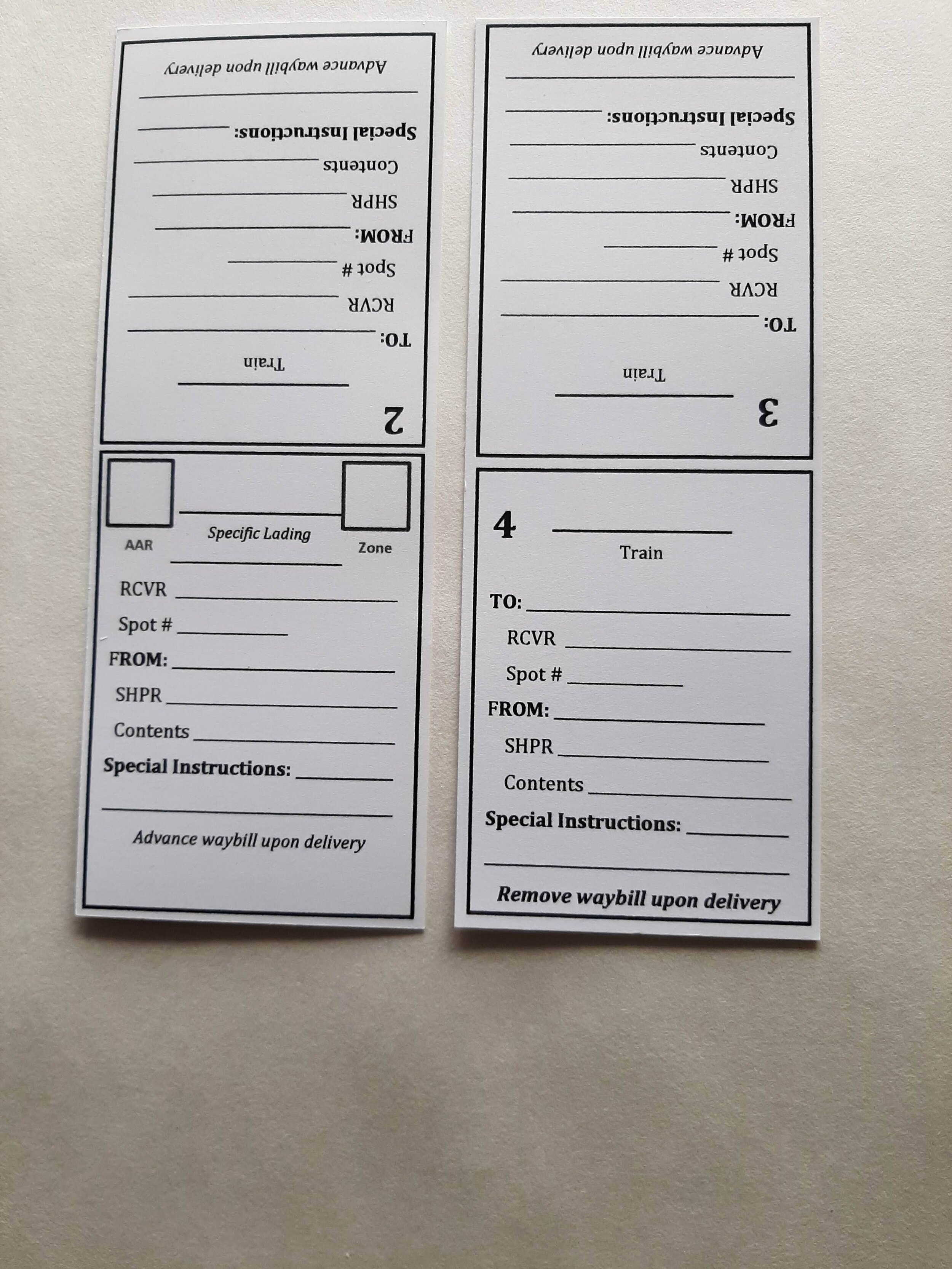

Waybills were also done in Word and printed/cut at Kinkos. Worth the cost. Because the car cards are “bottom loaded” the data is arranged in this manner. These are 4 position waybills with the first position called out by the AAR code for the car type. The waybill is removed and advanced/reinserted to the next numbered position upon delivery to each location. Position 4 tells the crew to remove waybill or advance to position 1.

AAR code on waybill matches the code on the car card: “TC” = “Tank-Chemical.” Some car destinations are purely prototypical, and some are purely whimsical- gotta keep the visitors entertained:)

The Zone # reflects the zone the car is heading to. In this case it’s heading for Walton, VA, zone 19. Probably near John Boy’s house.

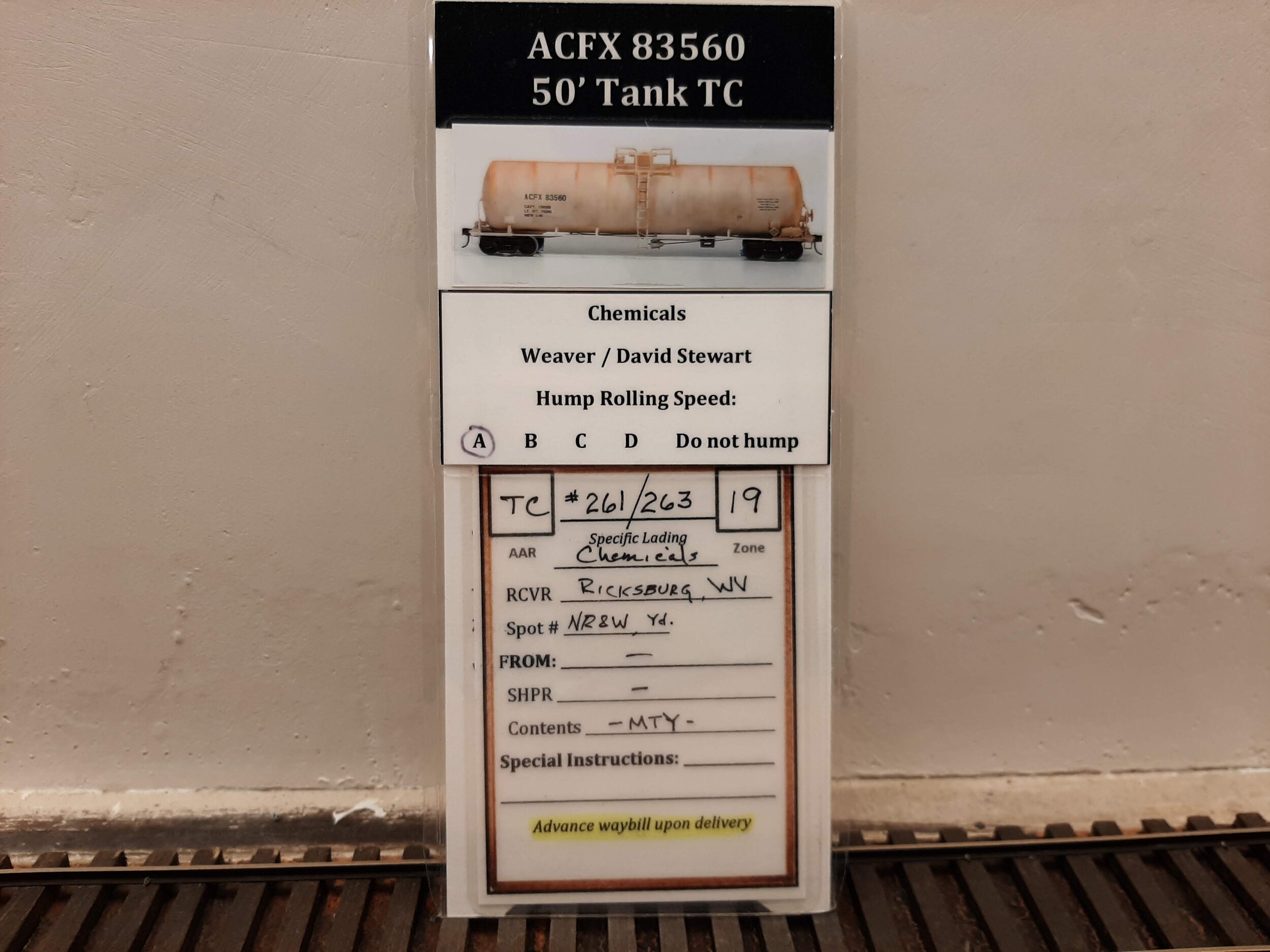

ACFX 83560 was humped at Millport’s 16th St. yard into the track for train #261 (or #263 if a second train is needed later in the session.) Odd #’s are southbound. It will be dropped at Ricksburg, WV and switched into the outbound NR&W track. #261 crew advances the waybill to position 2 and gives the card to the yardmaster.

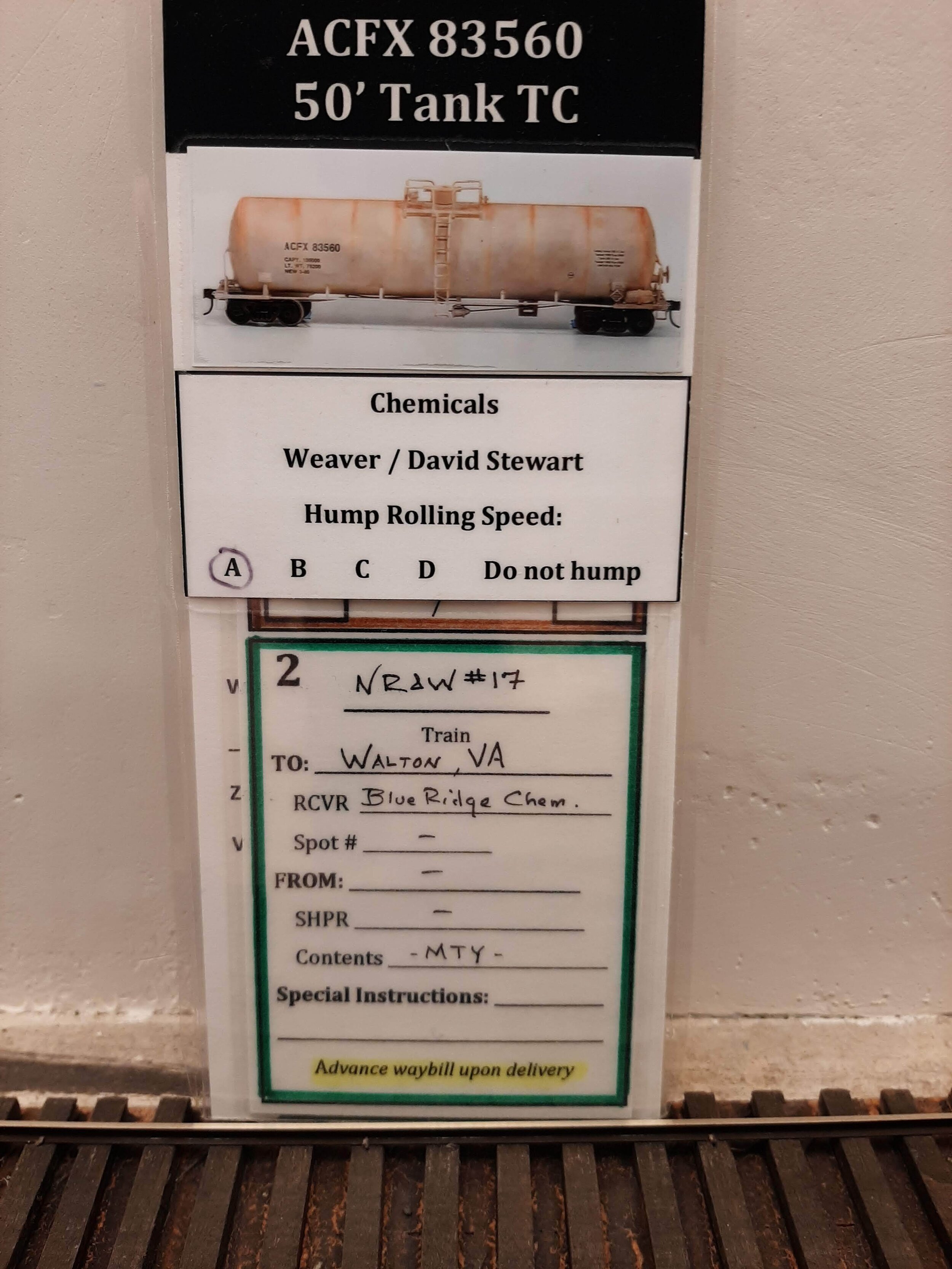

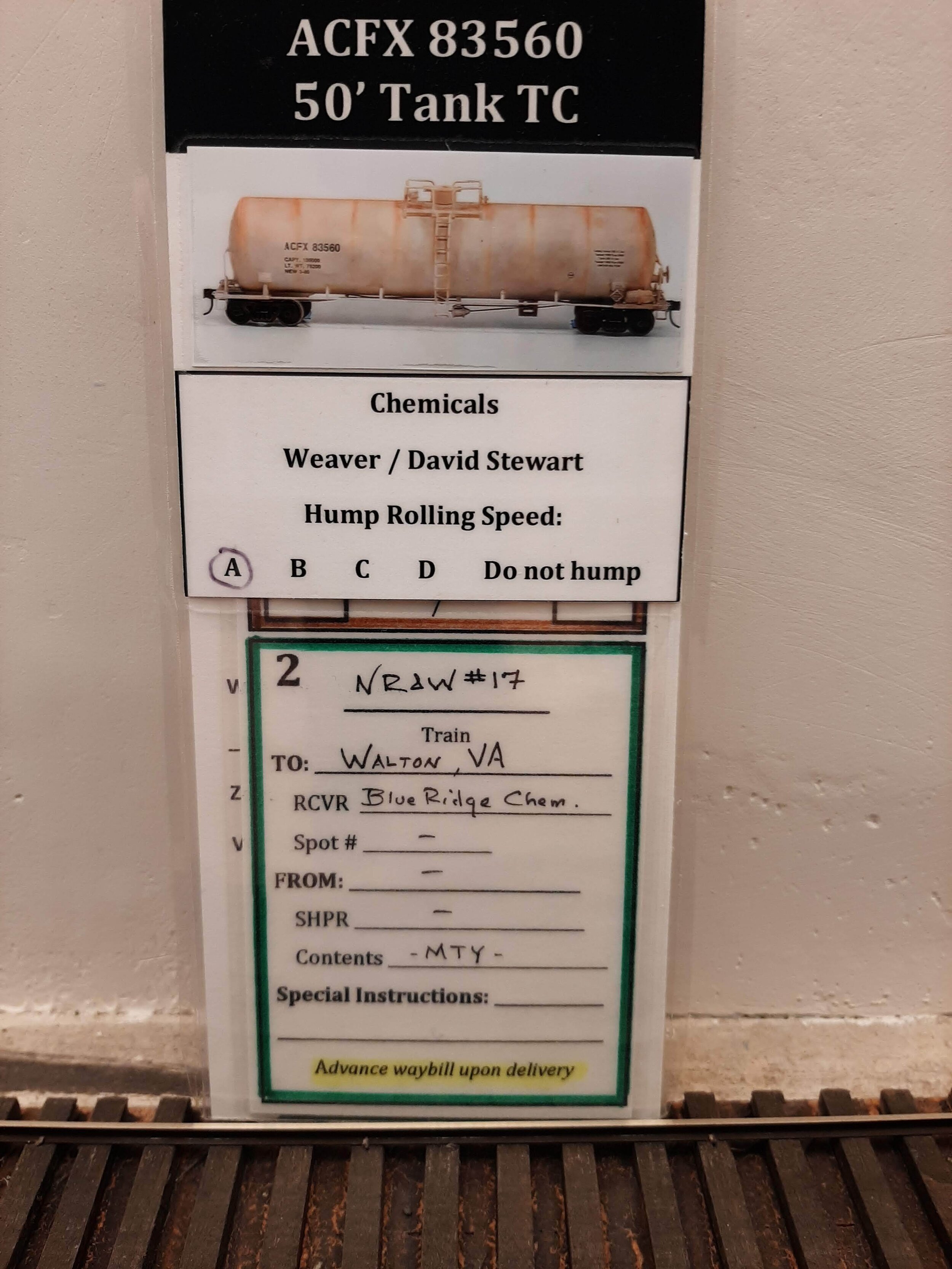

NR&W #17 arrives from Willow Creek via minimal trackage rights and later departs, this time with ACFX 83560 in tow. Crew advances waybill upon completion of the run (into staging).

Having been filled with muric acid, our tank is returned later on NR&W #17. #17 “turns” (returns) at Ricksburg, WV, so ACFX 83560 is left at Ricksburg, and switched into the track for when #262, or #264 passes thru town enroute to Millport, O. #17’s crew advanced the waybill as instructed, and gave car card to the YM.

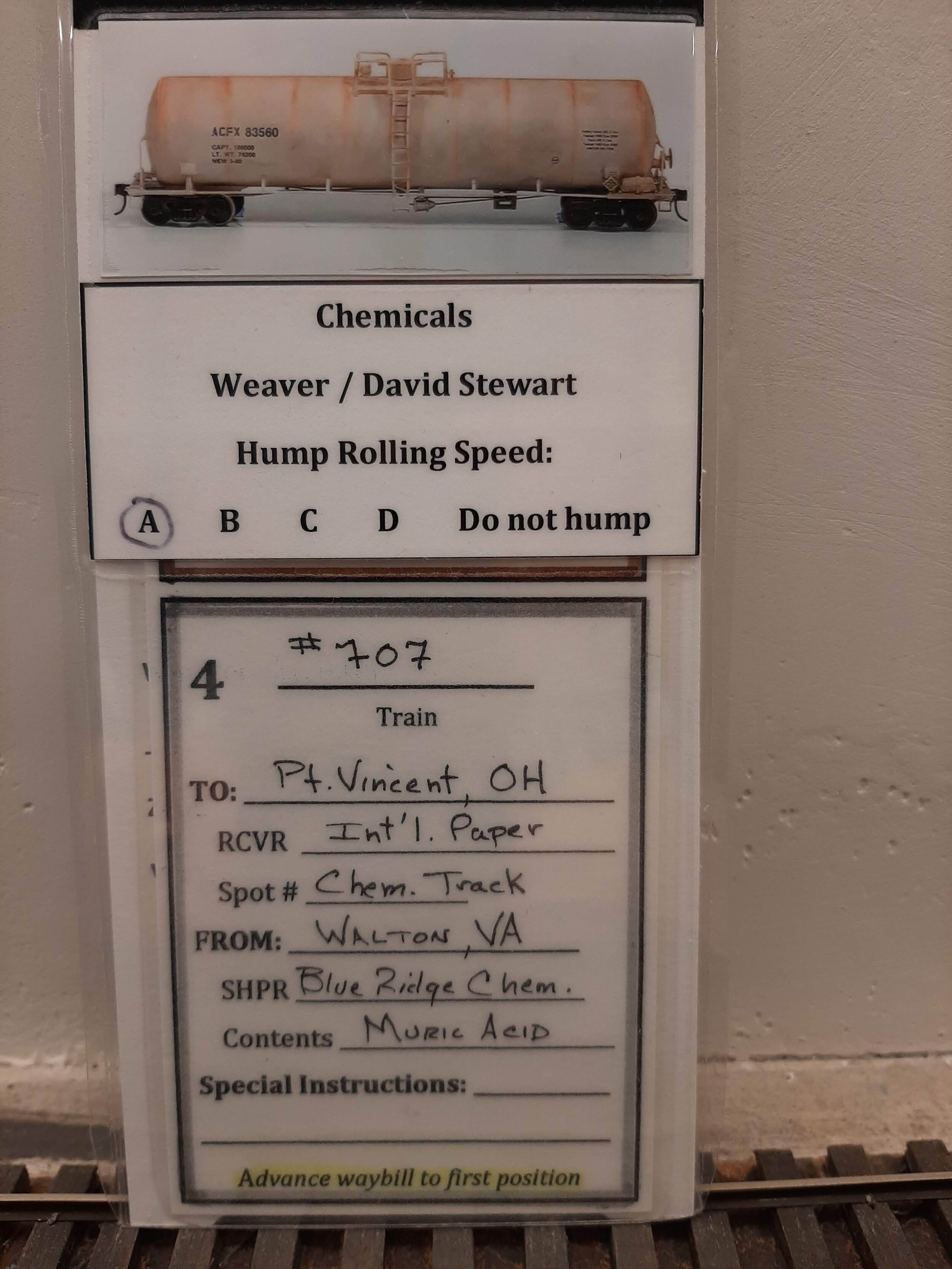

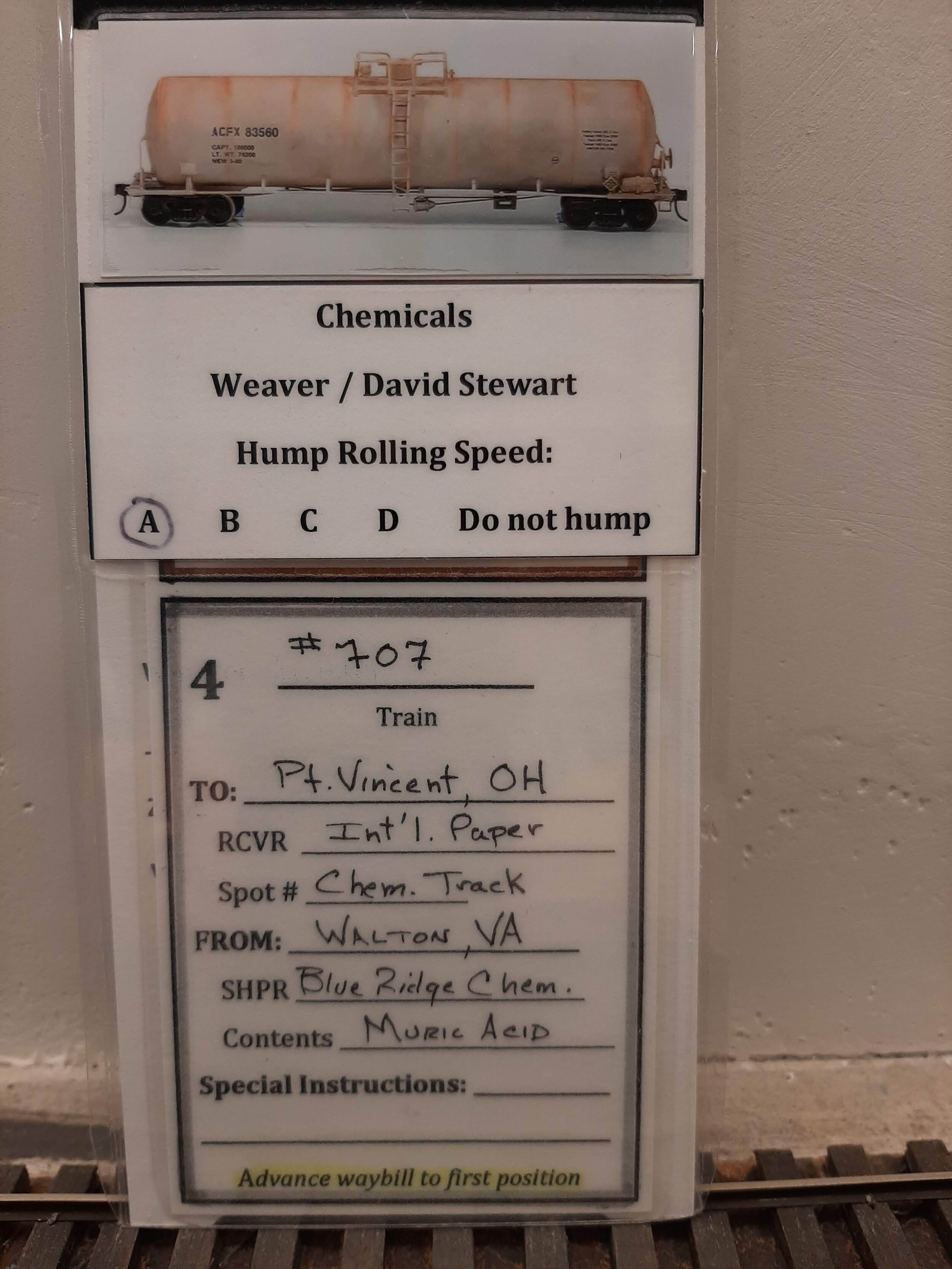

Arriving in Millport, ACFX 83560 is hump classified into the track for #707, “The Bay Switch” to Bayfield, O and return. It will be set out enroute, per spot #, on the Chem Track at International Paper in Pt. Vincent, O. Upon set-out, the instructions say to “Advance …to first position”. It will thus next be sent south and repeat the cycle.

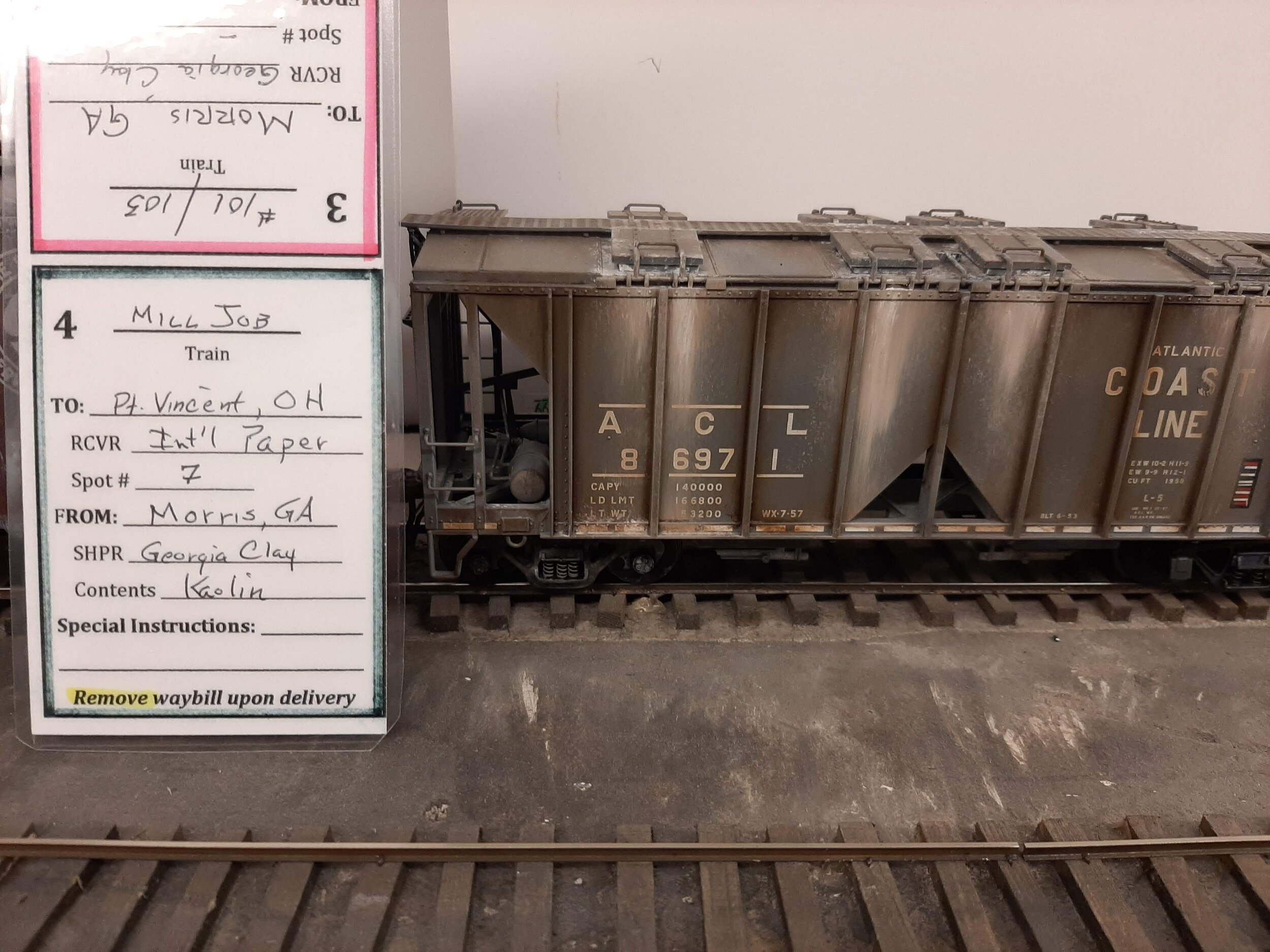

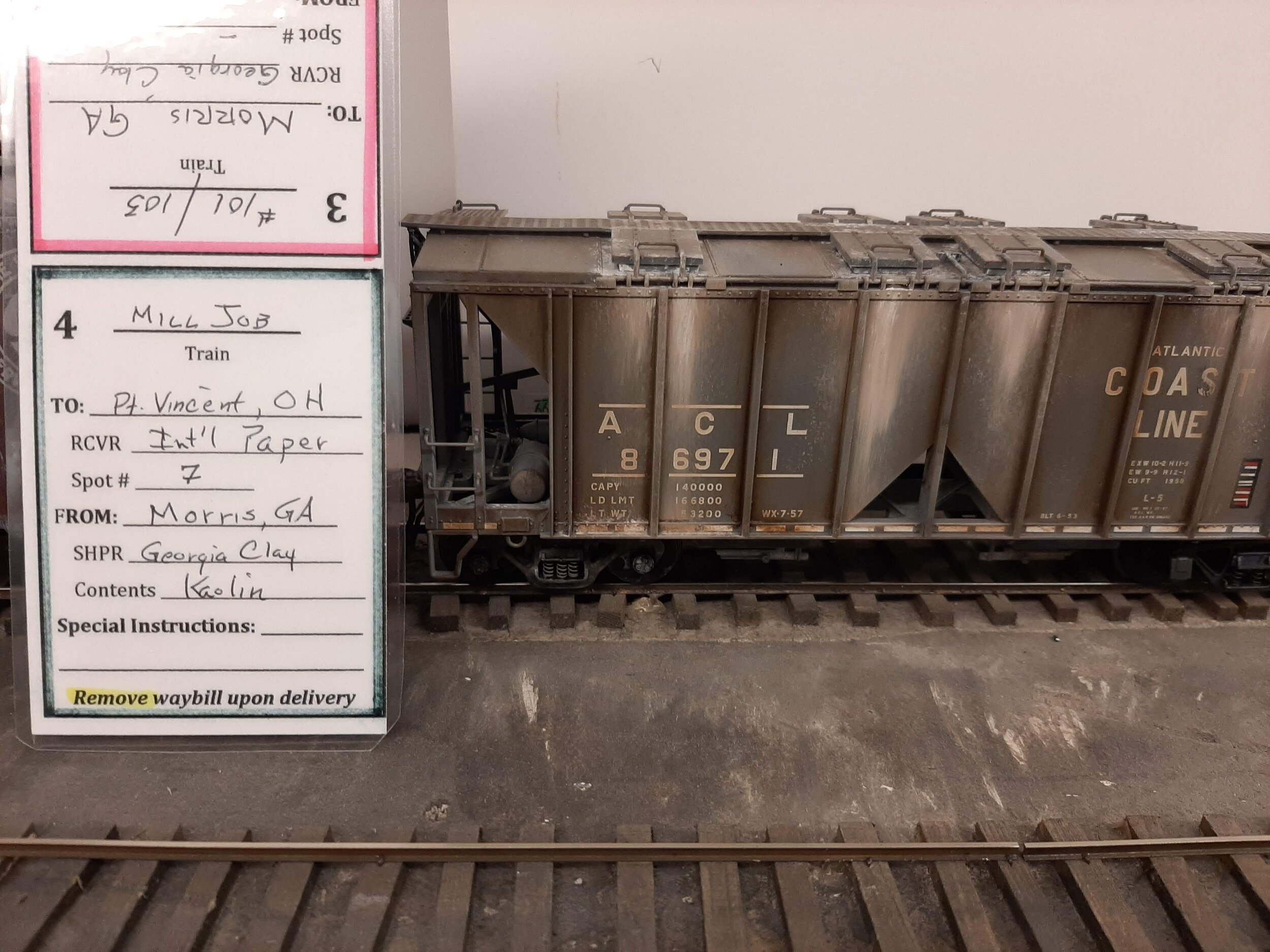

This waybill says to “Remove..” when delivered. Thus ACL86971 which carries kolin clay for paper making will return to it’s car card MTY destination. (see Operating Positions page). Of note is the use of colors on the waybill. This is for help in classifying in the yards. My crew needs all the help they can get….

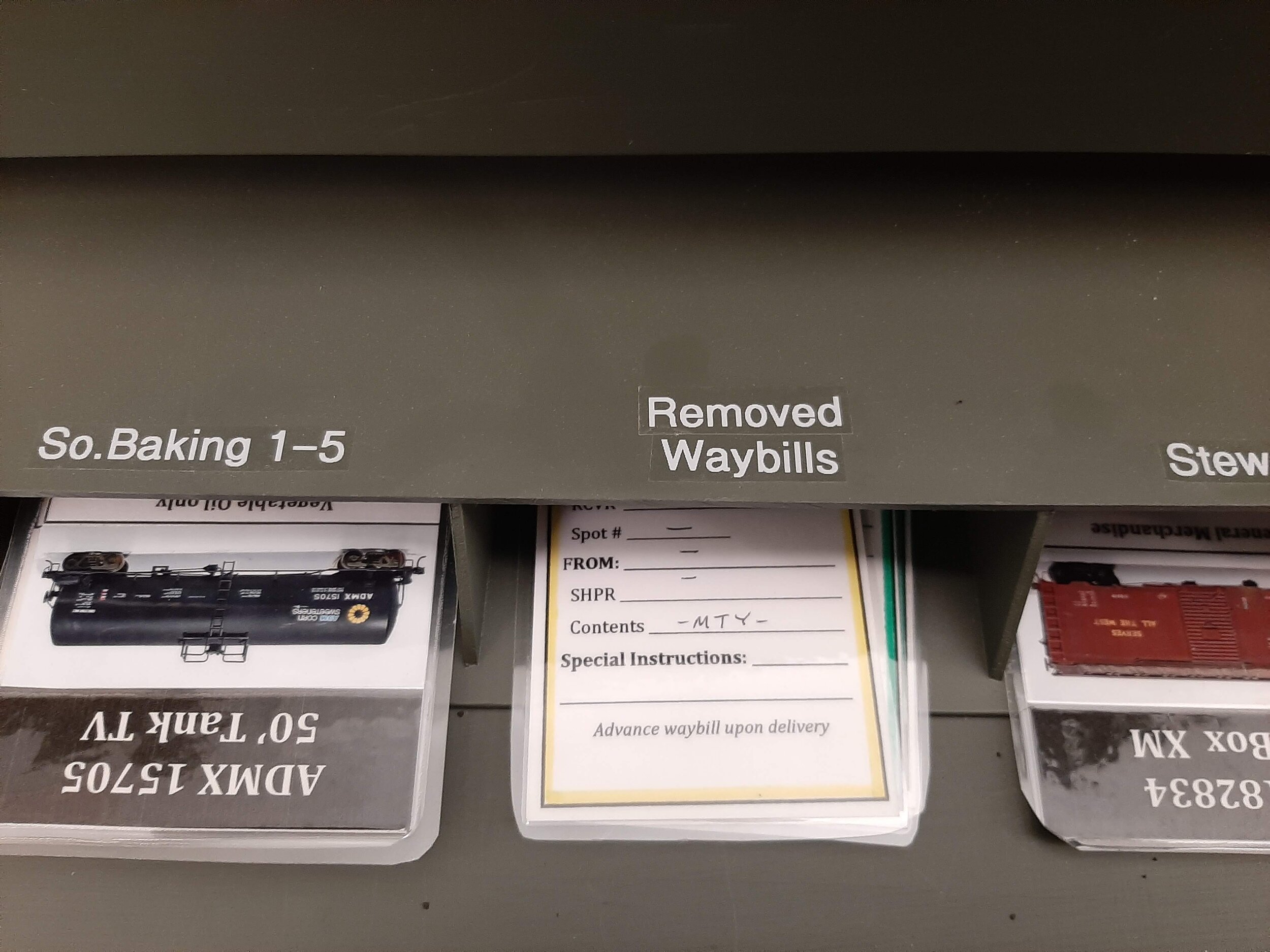

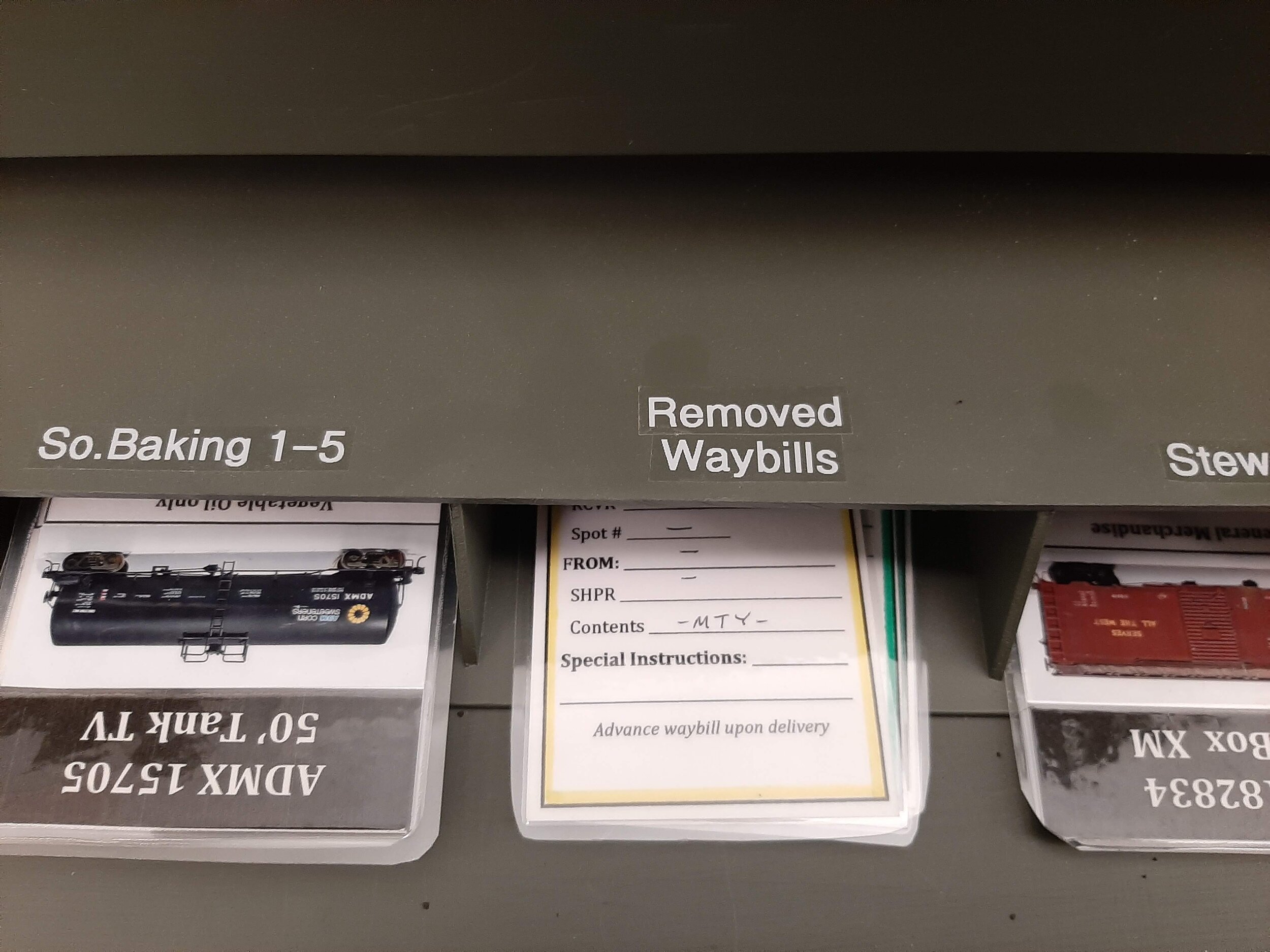

When cars are set out, the waybill goes into the industry card file. A separate “Removed Waybills” file is also near each switching location.

Horizontal working space is always at a premium, especially as the layout becomes completed. Here in Millport, and Willow Creek below, car cards are advanced. So…

a swing out work shelf provides a place for crews to lay train packets, advance waybills, and just hold stuff.