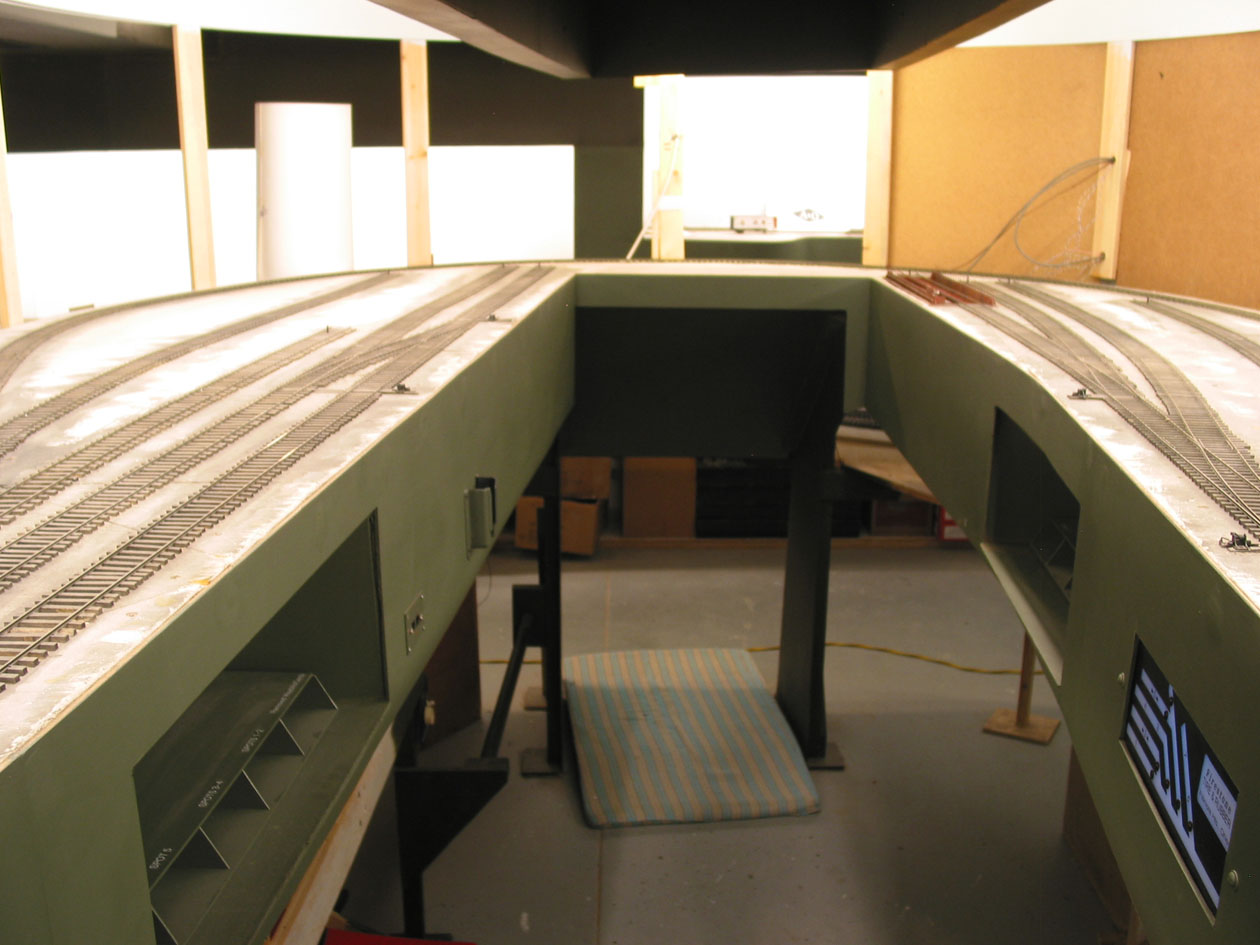

Cross members have been added over the Dogtown staging yard to support the plywood of Millport's Havens Yard. Black paint was applied to add to the dingy environment of this under-city scene. These lower-level staging yards are visible from the Millport aisle. Lighting will be by dimmed rope light behind the front fascia, with ocassional trackside bare bulb lamps.

This view will be visible upon completion. The notches in the cross pieces are for future track wires to be pulled taught to their Fillmore Hts. aisle bus power wire, thus keeping them from drooping into the scene. Upon attachment, they too will be painted black. Removable concrete walls will run the length of this yard completing the scene. Now to find some stray dogs for this Dogtown yard.

Framing in the Point Vincent area. White (and brown) cardboard has been stapled to the sides of the Slausen Cutoff and staging yard leads to protect against any equipment potentially hitting the floor as this lower trackage is hidden from view. It is accessible from the inner Fillmore Heights aisle.

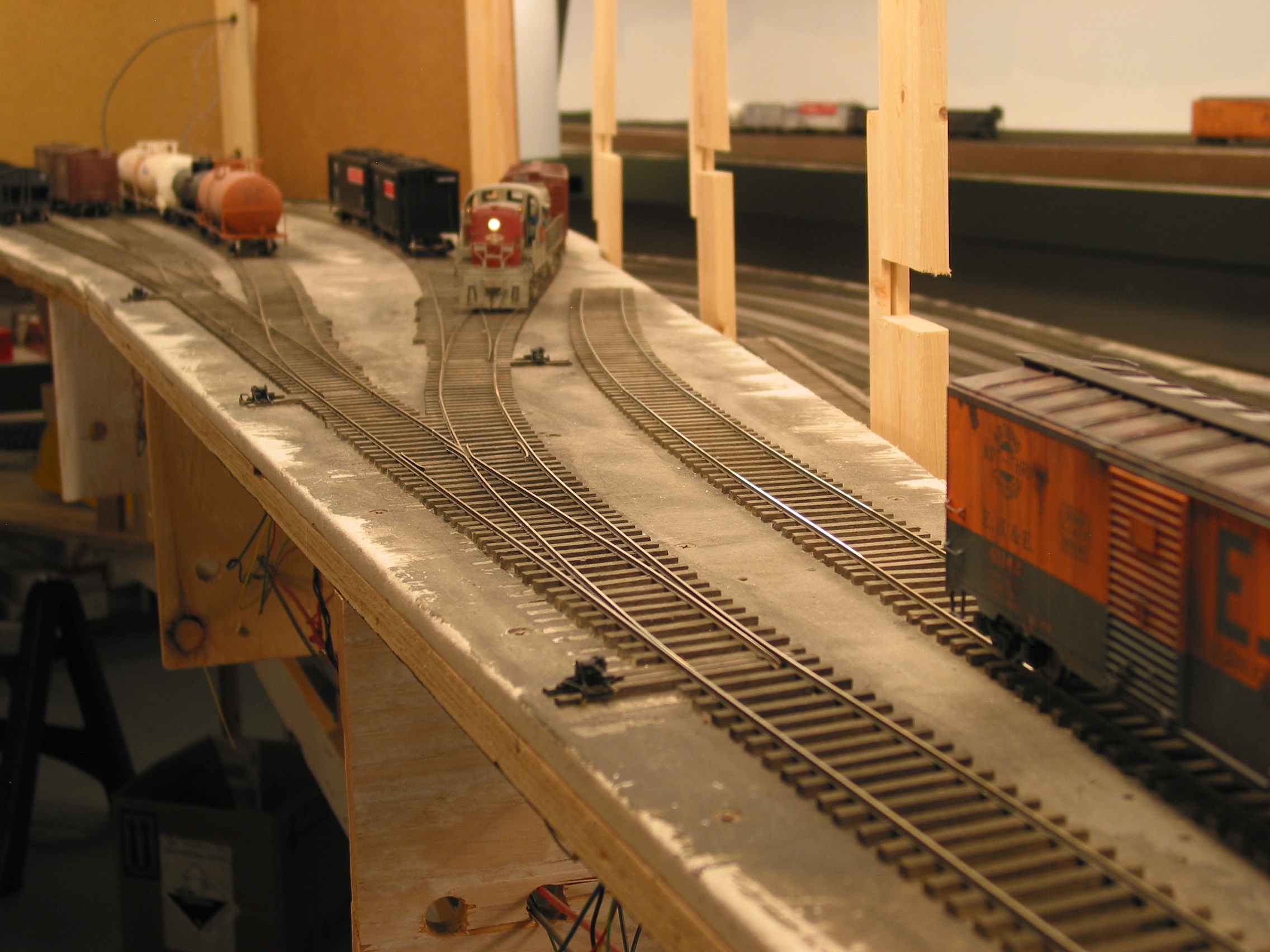

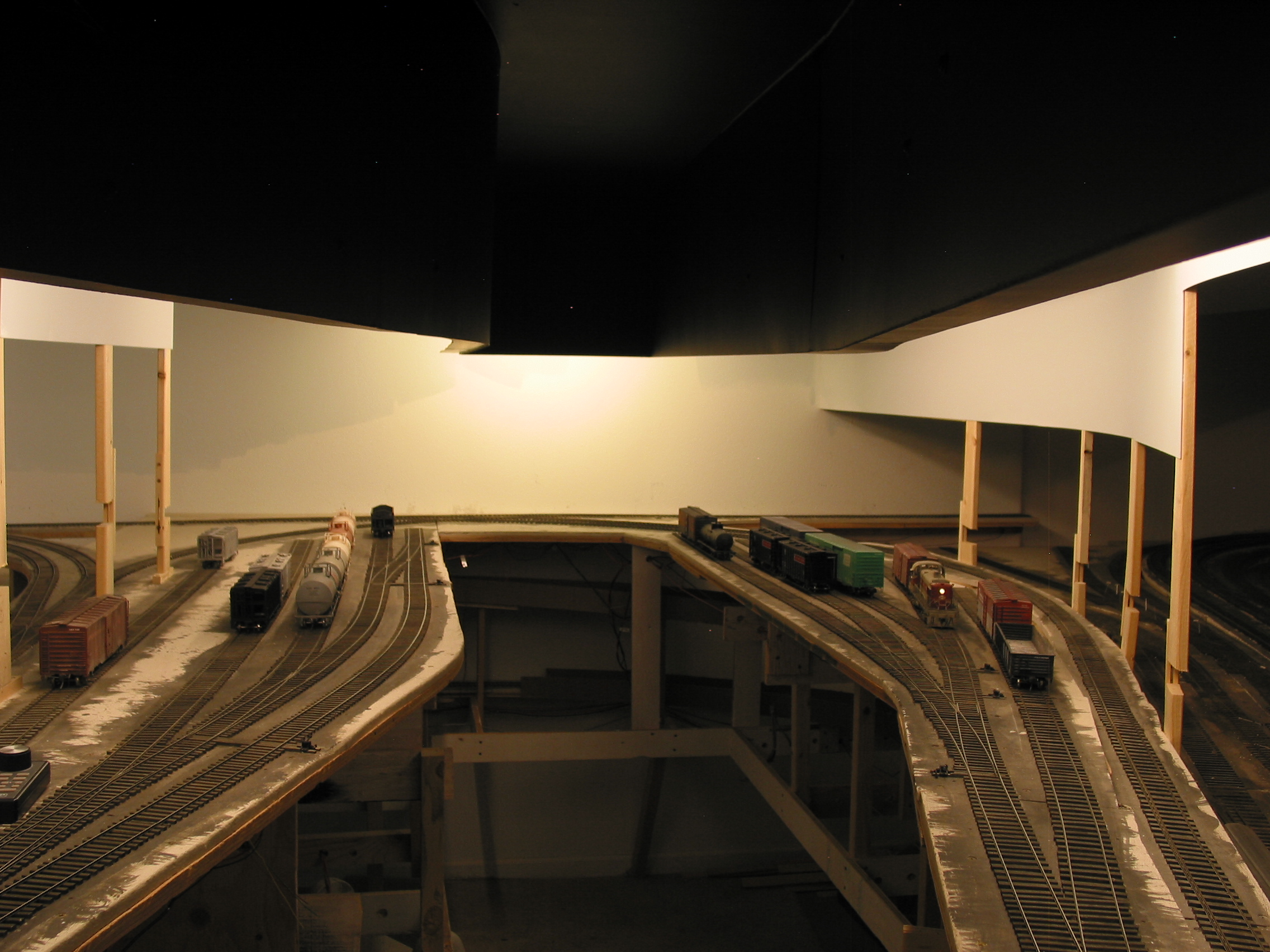

The return loop, Slausen cutoff (lower) and the Havens Yard lead into Millport (upper) snake between the supports for the above Bayfield and Fillmore Hts. trackage. With several tracks and scenes interwoven in this area, the framing required continual rethinking. (Many thanks to Bill Wood.)

The return loop, Slausen cutoff (lower) and the Havens Yard lead into Millport (upper) snake between the supports for the above Bayfield and Fillmore Hts. trackage. With several tracks and scenes interwoven in this area, the framing required continual rethinking. (Many thanks to Bill Wood.)

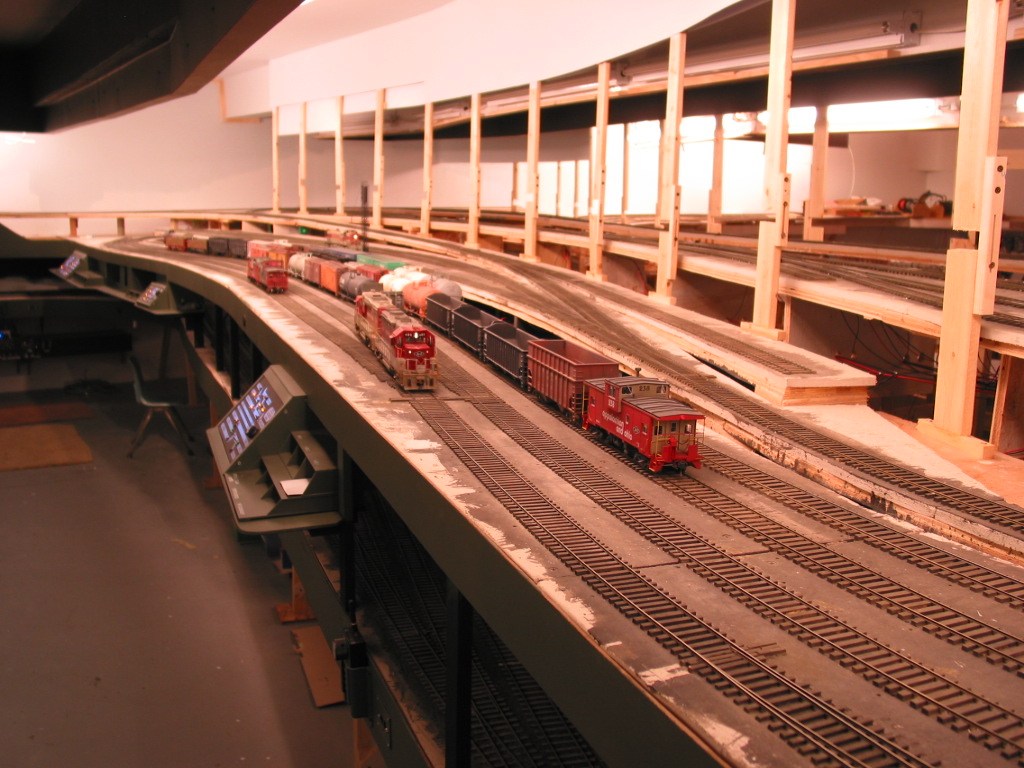

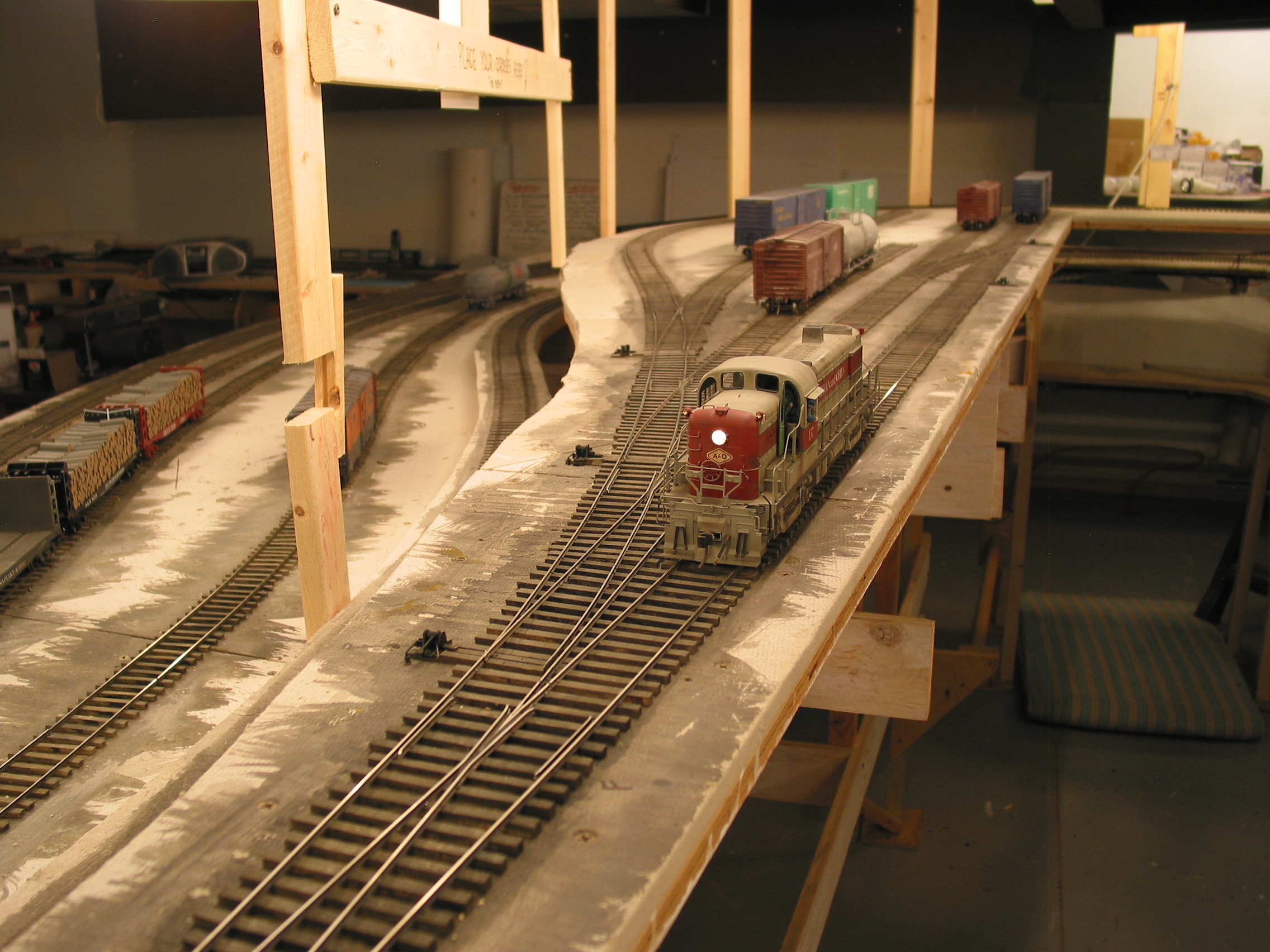

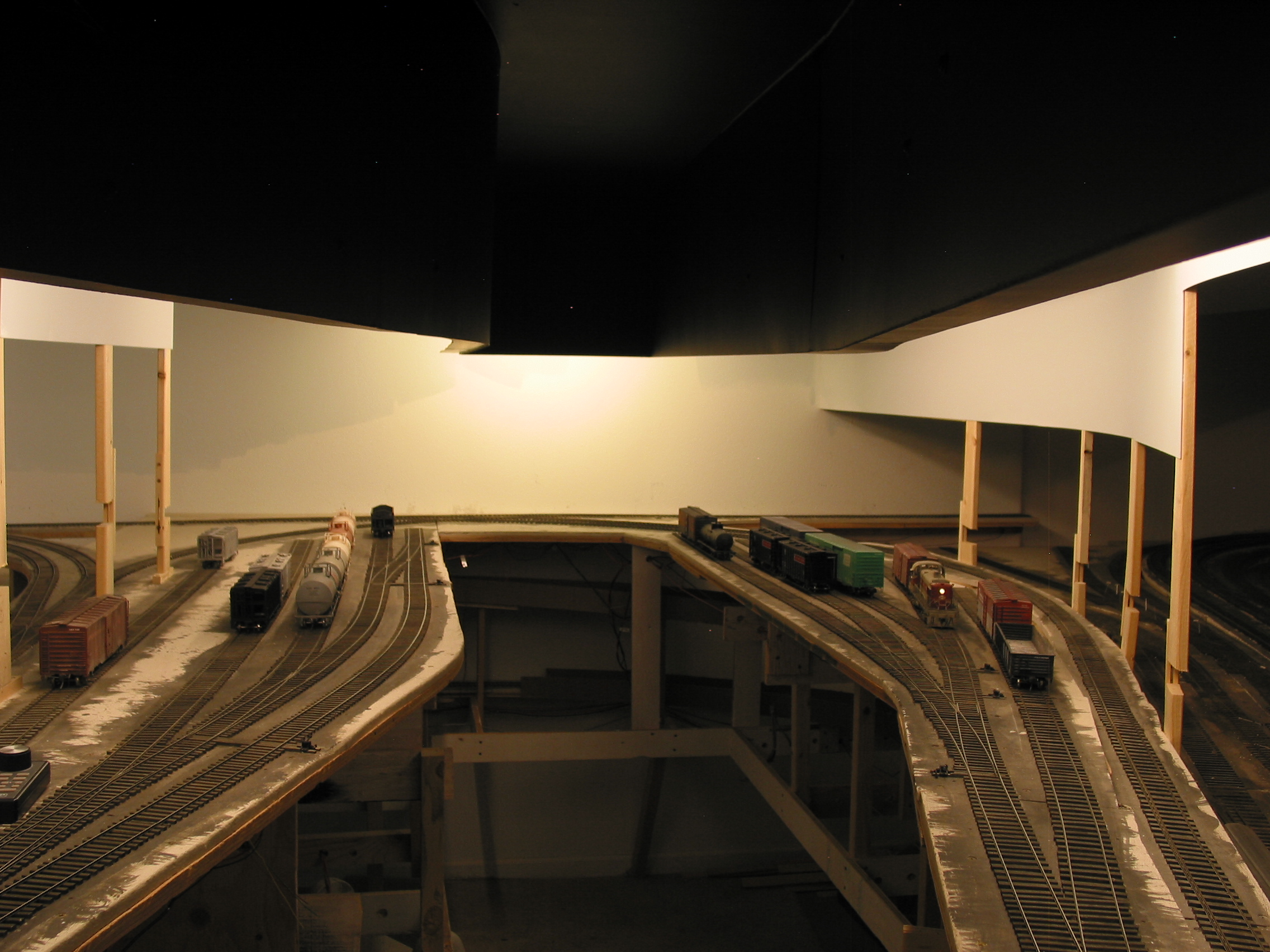

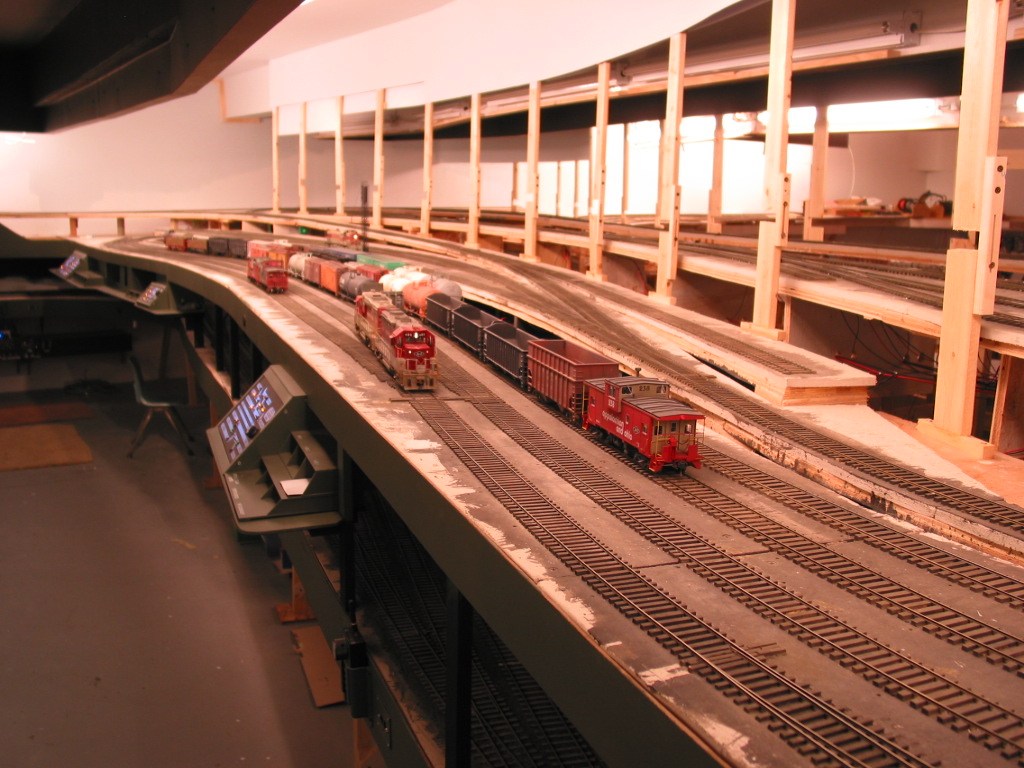

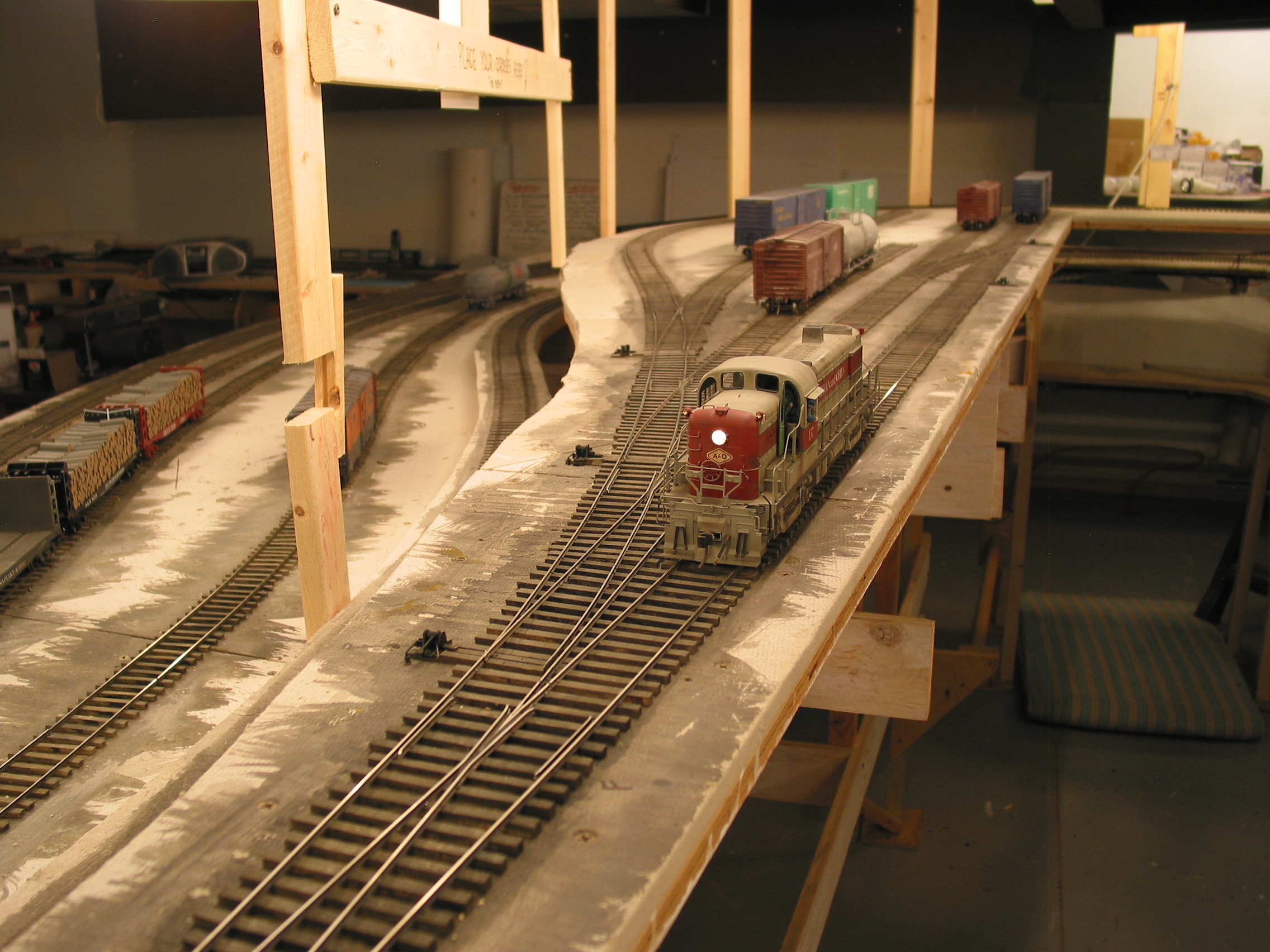

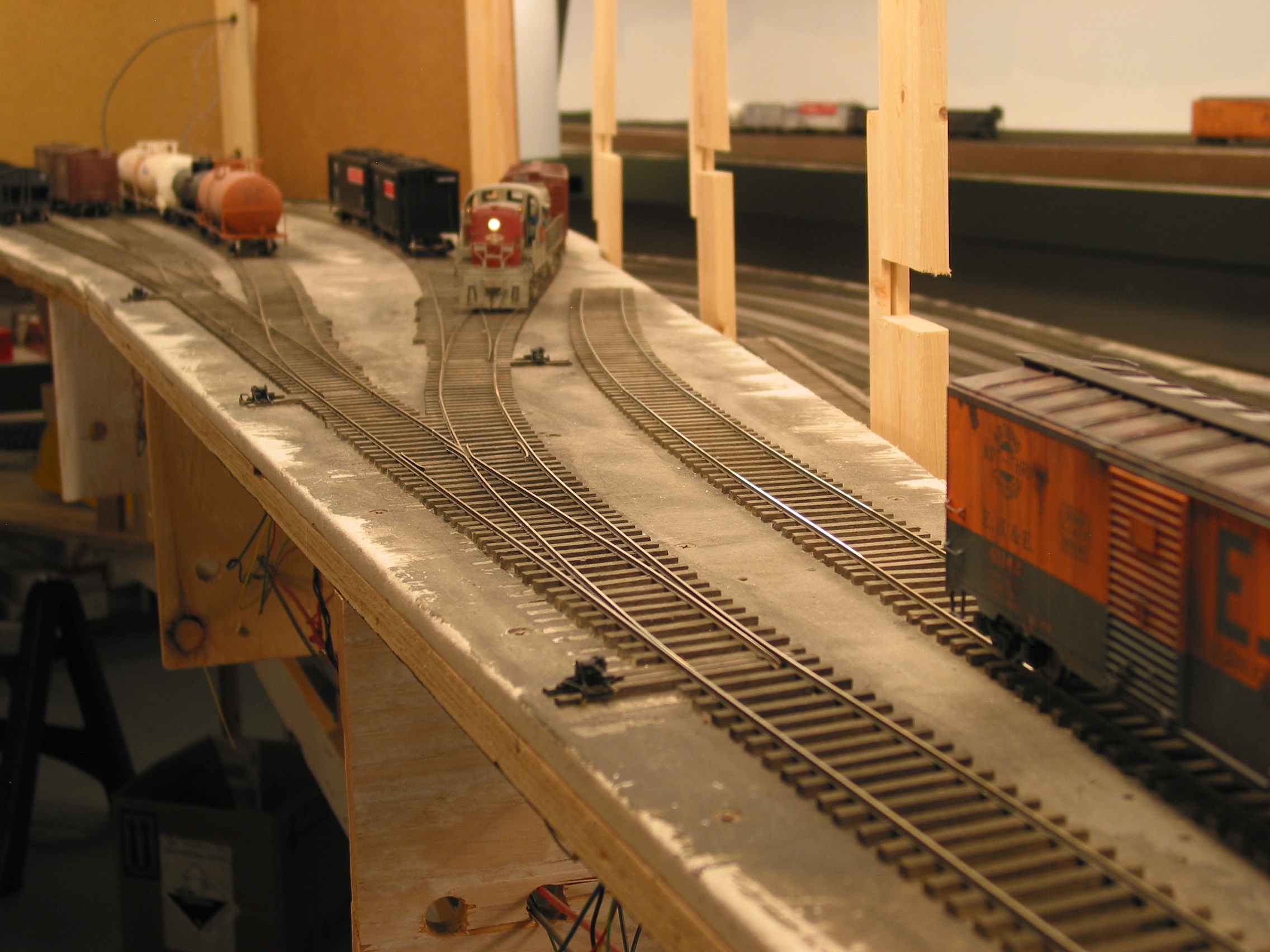

A lapse in keeping a photographic log advances Phase 3 construction to the point of having Millport's two yards in place; Havens (Arrival/Departure/Engine Service) on the left and 16th St. (Hump Classification) on the right. Below are Dogtown staging on the left and Taft Ave/Willow Creek on the right. Craig Linn and Bob Sobol in the distance.

The crest of the hump on the right for 16th St. eight-track Classification yard. Foreground is reefer storage, team track, and switching runaround. Mark Linn laid most of the class yard rail.

North Havens (Boulevard) Yard. A backlighted plexiglas panel (great for nights ops) has been added with sections for the upper wye and its connections ("Wye Knot") and for North Havens. The car card file is sized for the A&O's O scale-sized laminated photo car cards (3 1/2 x 7 1/4")

The North Havens work station. The engine service panel has been added. Car card files lay flat on A&O 2.0, allowing their surface to be used as work space. This also keeps the fascia clean, providing an uncluttered bottom edge/border to set off the railroad. A couple of "storage cubbies" separate the file boxes. Pop can shelf on each end. A rope light just behind the fascia over the flat work space provides light to this area for night ops.

Overall view of Millprt's Havens Yard. A double-sided styrene skyboard backdrop has now been added, encompassing the Fillmore Heights industrial switching area (right). Actual RR lighting has been installed as well. (See "Electrical" for lighting data) Many building flats to make!

Unlike A&O 1.0, I decided to paint the ceiling over the aisles and light valences as dark color ("Deep Sage"). It is amazing how much this made the ceiling disappear and brought all the attention to the railroad.

The Central Havens panel. Even in normal room lighting the backlit plex makes the panel diagram and its data stand out. Dogtown staging yard below.

At North Havens a train is coming up from the Dogtown staging while the doodlebug sits at the site of the future passenger platform along Havens Boulevard. The RS3 is "in the engine house."

Across the aisle, a car crests 16th St. hump as RS3 137 passes underneath and into the 16th St. industrial area.

The 16th St. Industrial District is split into two ends. This end features a wholesale grocery warehouse, and reefer ice dock, the American Boiler Company, and the 16th Street Team Track. The hump lead rises thru the middle of this area.

A lone reefer sits along the future ice dock while a gon sits on the loading track for the American Boiler Co. Removable inbound sheet metal loads and outbound boilers will require the switch crew to play put-'n-take with the car loads.

This is the other end of the 16th St. industrial trackage. A lead along the front of the class. yard (right) reaches the shelf area over the New River Diamond and ladder into Willow Creek, VW below. This arrangement provided a visual barrier for yard below, ie.-keeping WV out of Millport! It also provided a source of lighting.

Campbells Soup and Swansons Frozen Foods comprise the industrial sites at this end of 16th St. industrial. This provides a necessary destination for the iced reefers from the ice dock at the other end of this switching district. What a concept.

A look down the 16th St. 8 track hump yard. Typical of hump yards, it features three 3-way switches. Yard length is approximately18 cars.

Mechanical retarders pinch the wheel flanges to slow the cars, just as in the prototype. The weight and mass of O scale precluded air retarders as is sometimes used in HO. Felt was glued to the surface that pinches the flange. The brass tubing will be dressed and detailed to look like the actual thing.

Work station for the 16th St. hump shows (left to right) panel with route selection, magnet board for "train tiles" which are placed on the panel to denote the train/track designation, a car-to-which-track list which is made up before the train is humped, and the start of card files with the car card for the one being humped laying a top the file. The CNW GP9 is by Craig Linn.

Having just passed the Master Retarder, we're entering the first 3-way to our appointed classification track. Group Retarders will further slow as needed per track capacity. Much time was spent creating the "bowl" so unretarded cars will run-out to the end if the track is empty. The trick is having a quick release grade followed by a continually diminishing grade over 75% of the track lengh. And then a slight upgrade at the end.

The retarders are model airplane servos and a simple bell-crank mechanism with piano wire through brass tubing into the end of the retarder, much like moving switch points. Depending upon the route selected, the Master and one Group retarder actuate when the button is pushed.

Activating the retarders is done by pressing either the green button on the shelf, or using the corded red push button on the hand grip- for walk along operation. A styrene cradle holds the hump engine cab throttle for the operator. A Back-emf decoder allows for continuous, slow speed classification. There is brief learning curve.

Willow Creek is at the lower left and above is 16th St. hump class. yard. A throttle bin is located here for arriving/departing crews. Panel is for the Taft Ave. ladder (other end of Willow Creek) with a beige magnet board for holding train tiles when not placed on the track diagram. Train card files for the trains in staging are below panels.

The Dogtown staging yard panel found its home hanging on the lighting valence above Millport's Haven Yard. The back-lighting really shows its worth, even in this "daytime" environment.

Horizontal work space is always at a premium, especially in yard areas. So I made pull-out shelves to provide temporary assistance. They can be pushed in without disturbing paperwork, and it also makes the reach to back tracks shorter. Train card files for Dogtown are below. The red push button is for a timed electro-magnetic coupler on a rear track.

This view down Millport's aisle illustrates the convenient proximity of the two staging yard panels. The Traffic Manager operator will move trains between yards, and simultaneously move their corresponding train tiles from one panel to the other, (and their train card packets to proper files) to help keep track of what's where.

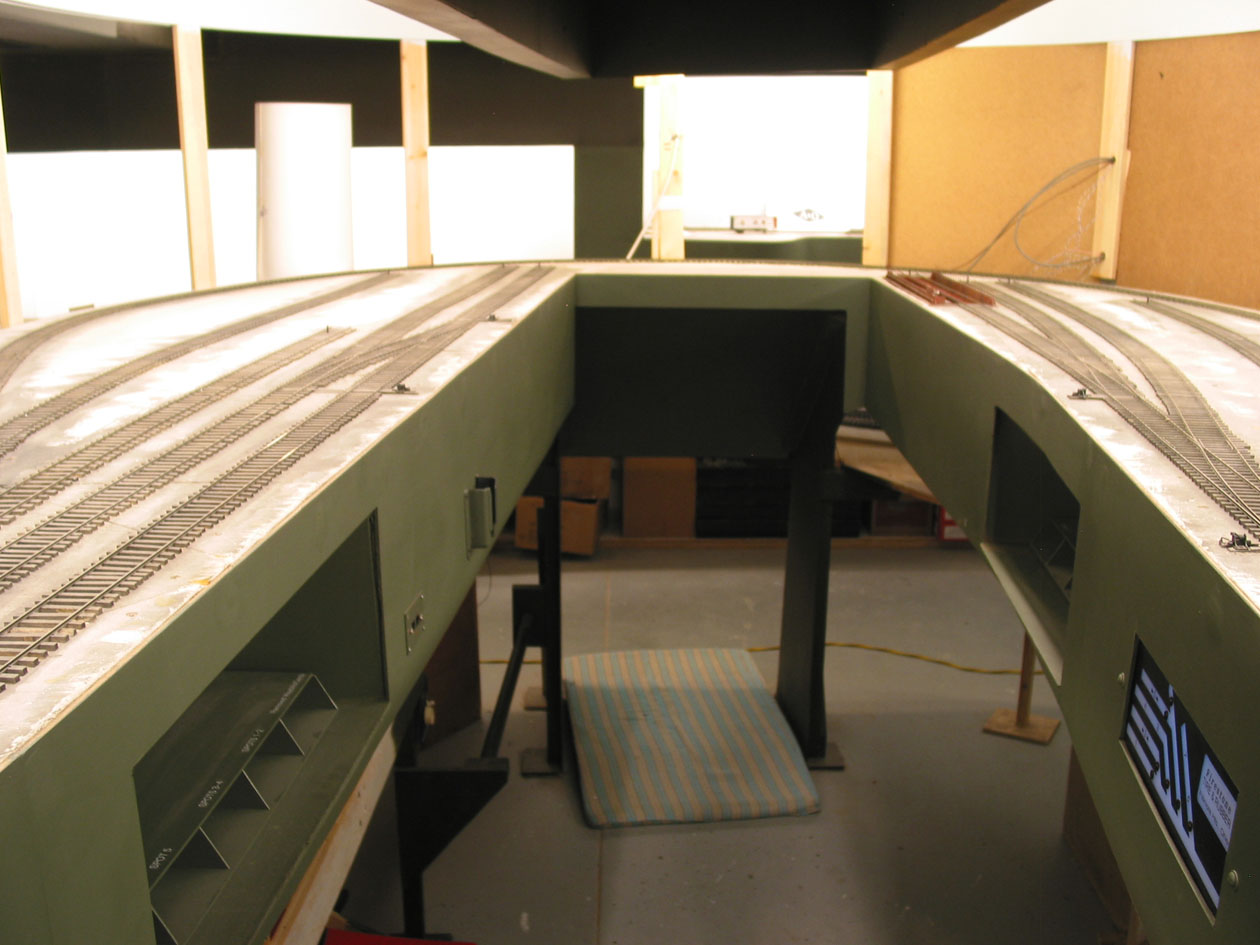

Fillmore Heights (pun intended) is the industrial switching district inside the peninsula blob that forms Millport aisle (to the right in this photo.) It is accessed by a true crawl under at the end of the aisle (where currently the foam mat is placed.) It is my "Bonus Room".....Under the garage! On the left is the future Ford engine and transmission plant and on the right is Firestone Tire and Rubber. Fascia and work stations yet to be added. Now all that crazy looking framing from earlier picture above makes sense! (?)

60' auto parts cars will frequent the Ford plant, with the back tracks inside the building. Given the narrow aisle width of 27" and the nature of the work, only one or two operators will be in this space at one time. Track elevation here is 53" and with the very vertical backdrop scenes, Fillmore is designed to be an intense, in-your-face, operating experience. This is a totally isolated 26' long aisle of industrial delight. Vince Griesemer and Jack Heir laid much of the rail in Fillmore.

Carbon black airslide hoppers are being set out at Firestone. The hopper in the foreground will be for the power plant located nearby to supply power for both Ford and Firestone. Without Firestones building flats yet installed, the 16th St. Hump is visible in the distance across the Millport aisle.

Because of the closeness of the track to the aisle, ground throws (HO) are used in Fillmore Heights. A bell crank wire actuates a micro switch underside to change polarity of the frog. The EJ&E box is on the loading dock track for Firestone.

Looking to the opposite end of Fillmore Heights shows the inbound tracks from Millport in the distance. A sorting and holding yard is on the right, along with a siding for Steelcase Mfg. On the left is an Owens-Corning shingle plant. The ceiling in Fillmore has received the same lighting and valance treatment as the Millport aisle.

RS3 137 completes a runaround move at Owens-Corning.

Fillmore's fascia has been completed, showing work stations at each switching area with car card files.

The crawl under entrance to this completely isolated industrial switching area was trimmed out with hardboard on all sides. A handrail here (left) and one in the outter aisle, assist operators regain verticality after going thru the chute.

Because the operation at Fillmore Heights is so up-close-and-personal, it uses ground throws. However turnout position indication is provided on panels via micro-switches on the ground throws. This will be particulary helpful in night ops.

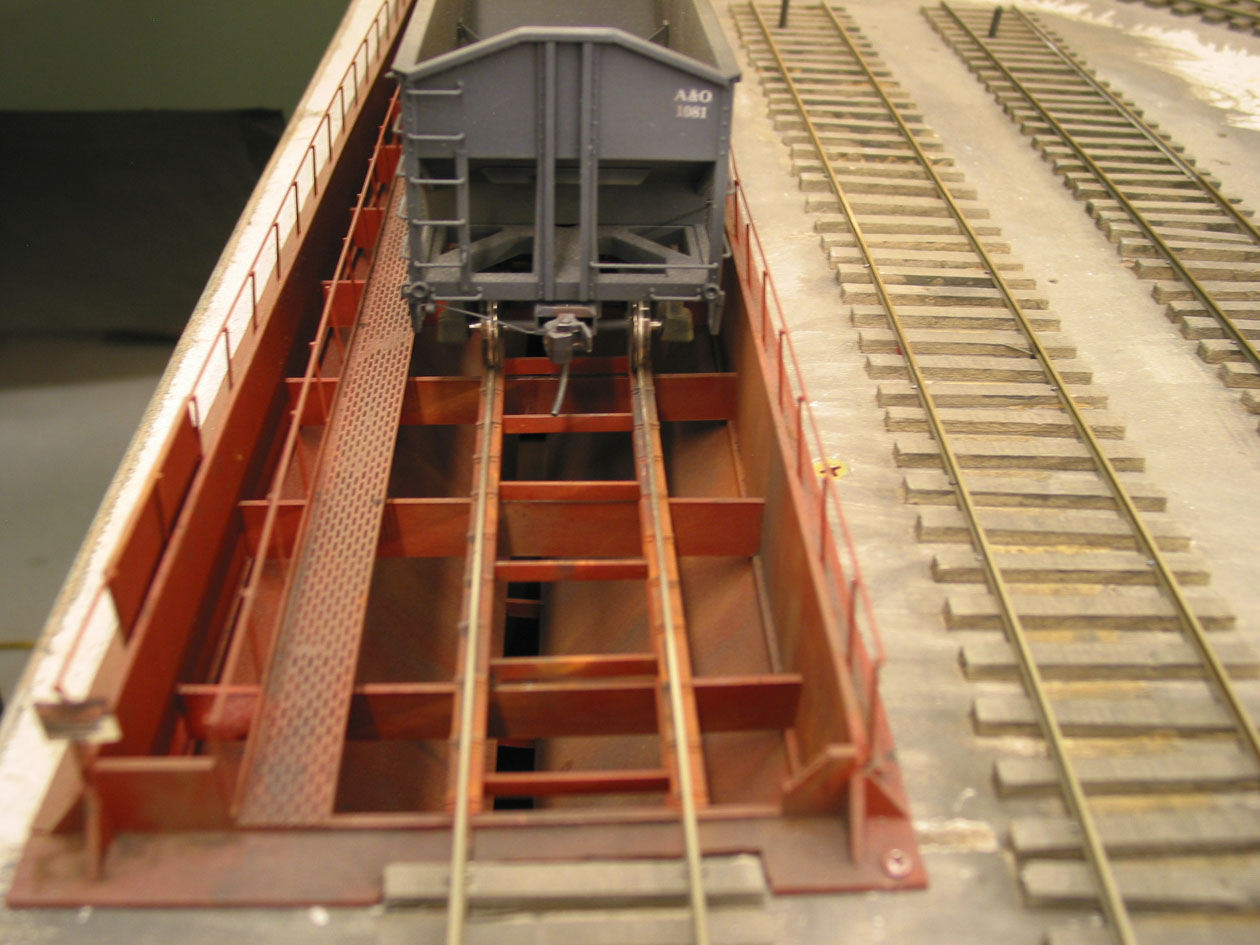

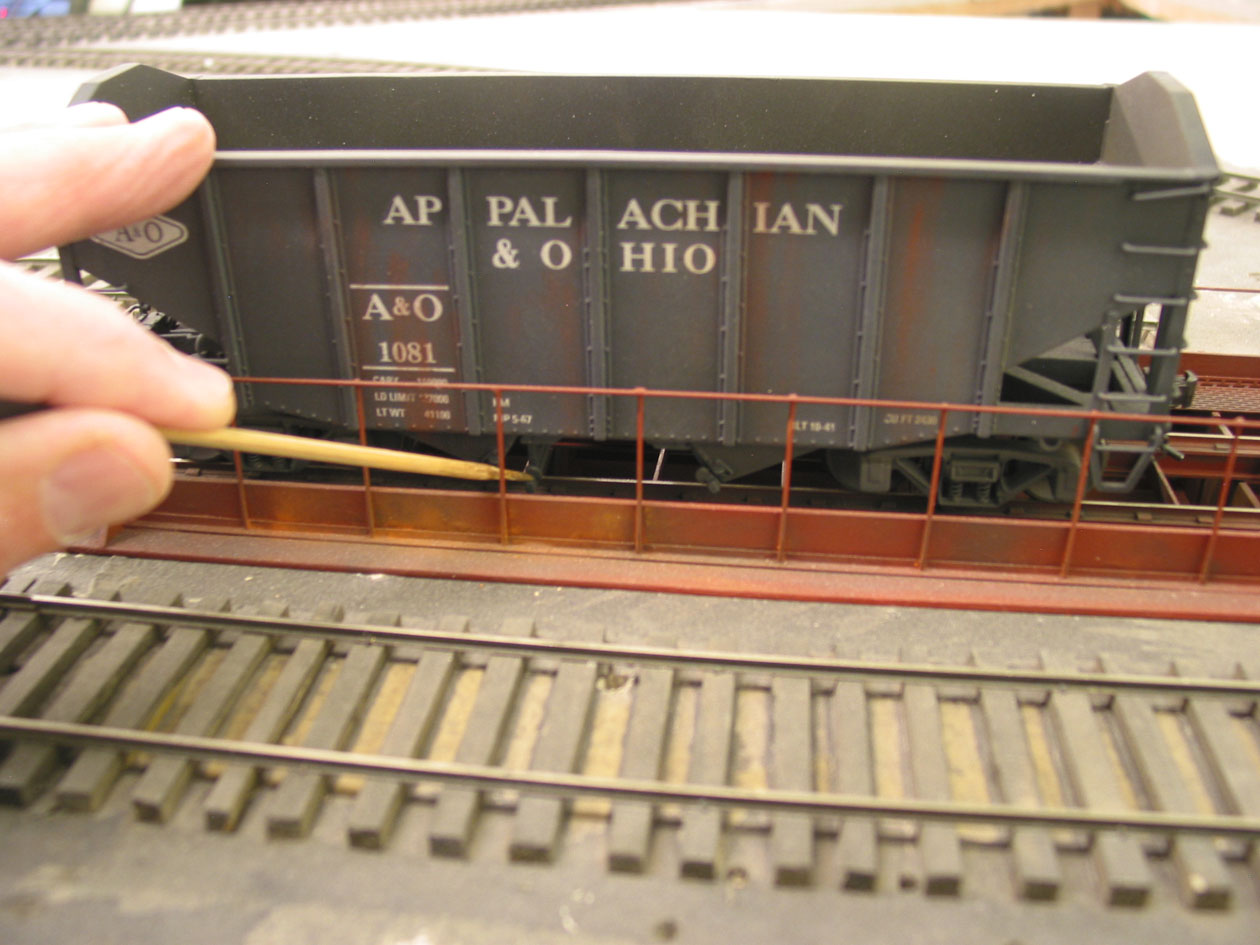

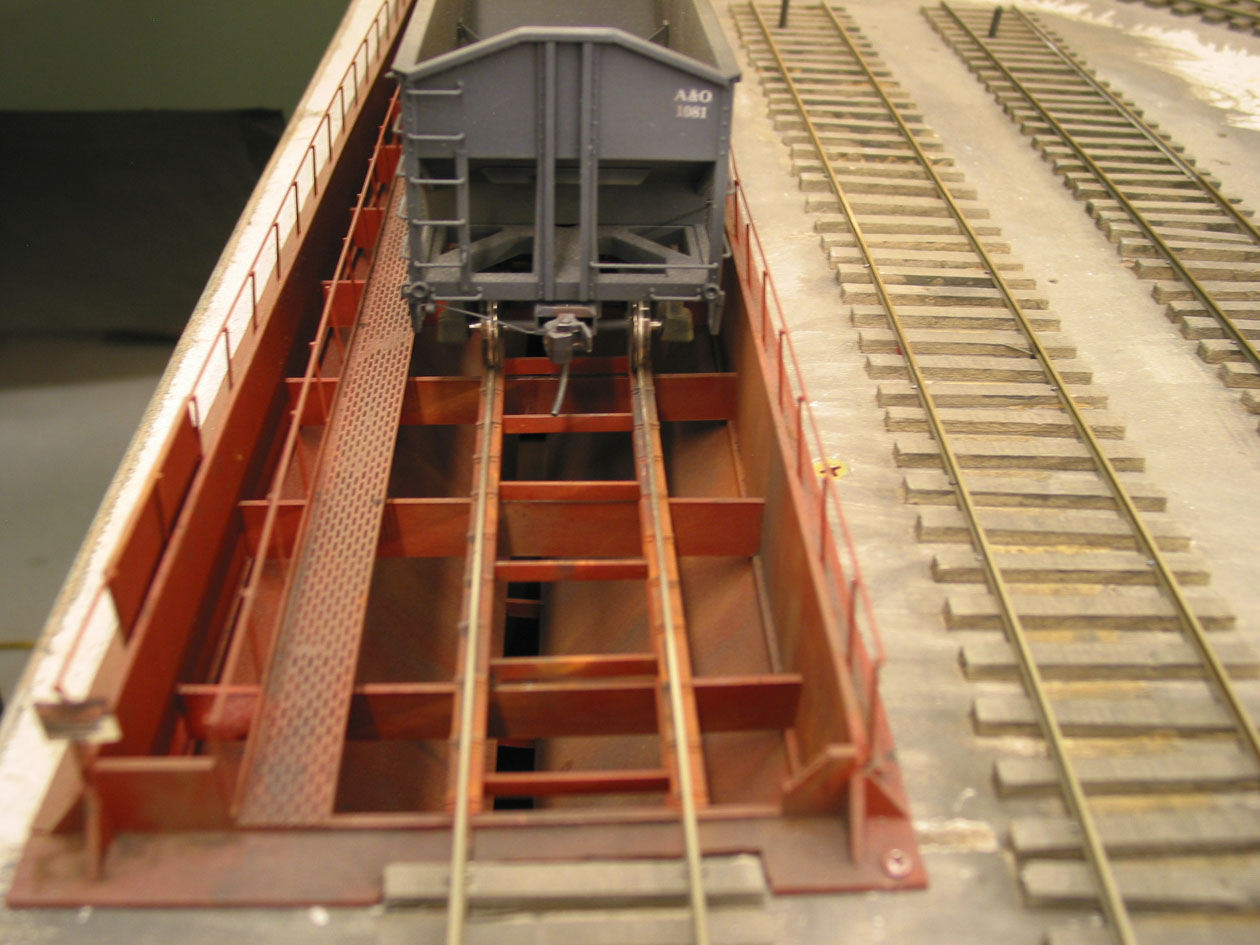

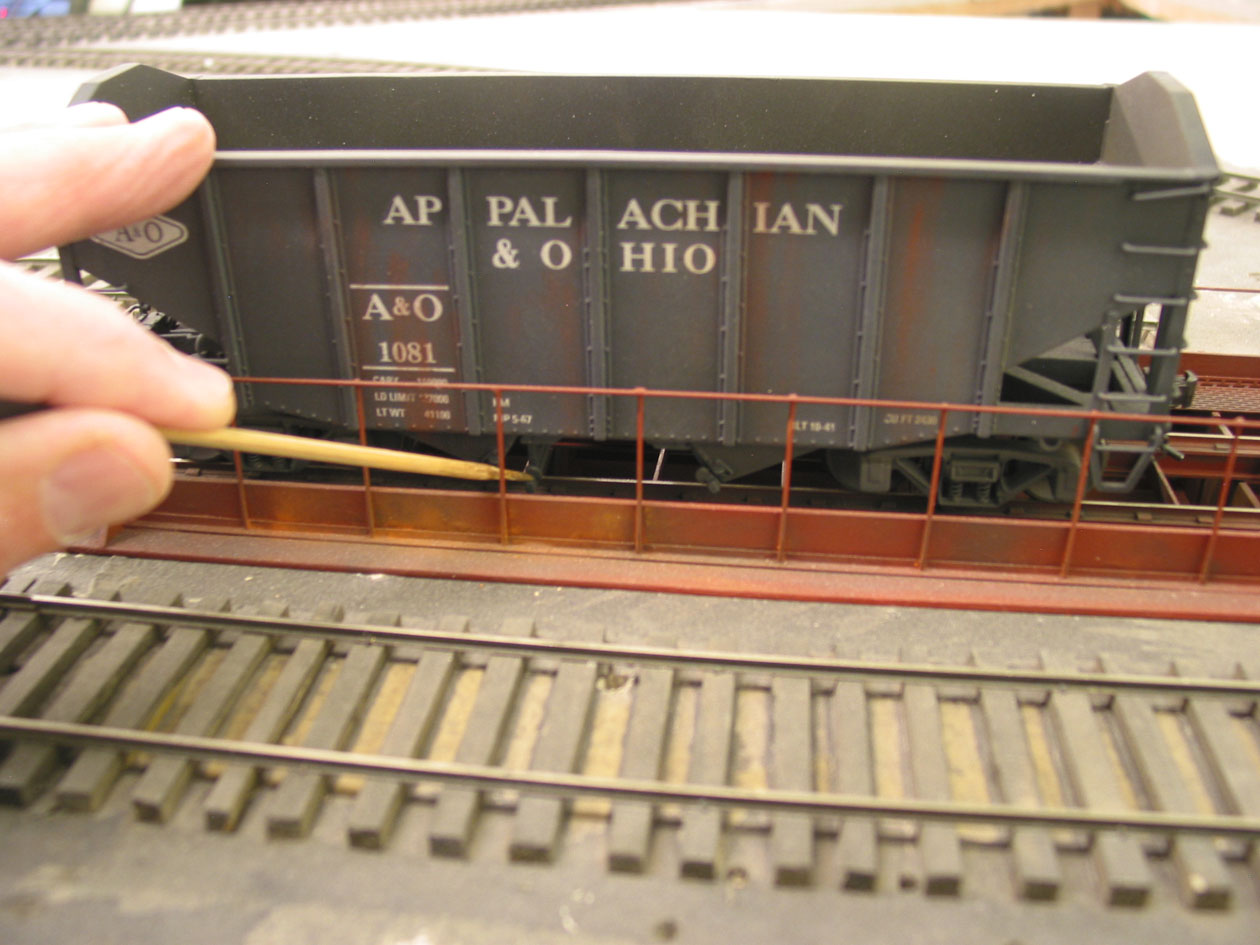

There are two coal dumps in Fillmore for industrial power generation. They were made from styrene and brass. Four such Buckeye Power & Light coal dump-trestles are planned for A&O 2.0.

Atlas fishbelly hoppers feature spring-loaded operating gates. As on A&O 1.0, they will be manually unloaded with a wooden skewer as each car is set-out at delivery.